SHARE ON:

Link copied!

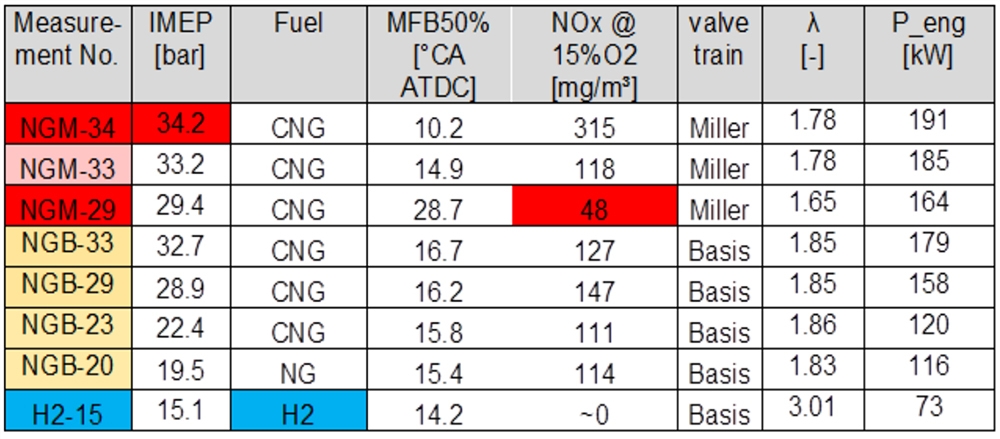

To study these effects in more detail, test bench setups, like using a 4.77-l single-cylinder research gas engine of the Chair of Internal Combustion Engines (LVK) from the Technical University of Munich (TUM), are a valuable option. Numerous research tasks concerning engine and emissions performances have been successfully carried out with this engine. Using alternative fuels, the engine vibrations can change considerably. One factor is the difference of the pressure in the cylinder during the combustion process, see the table and pressure curves below.

Different pressure curves of these alternative fuels have been measured on this single cylinder research gas engine. The combustion of pure hydrogen was also used for these studies. Even hydrogen with quite a low IMEP of 15 bar shows, that the torsional stress limit of the crankshaft is exceeded without a torsional vibration (TV) damper. Compared to the diesel engine, a 30% higher TV stress in the crankshaft for pure hydrogen can be seen, even with a state-of-the-art TV damper. In addition to that, the combustion of natural gas with an IMEP of 34.2 bar shows an overload of the crankshaft, even when applying a torsional vibration damper. In such a case, additional design loops for this application between the engine builder and the damper and coupling supplier are required for further design optimizations. Due to such studies, Geislinger has built up its knowledge also with respect to alternative, future fuels, to individually optimize the dampers and couplings depending on the engine builders’ concepts.

For more information, have a look at the paper related to this presentation: https://bit.ly/3x5UQqN

And you can also see a video of the presentation here: https://bit.ly/3h2ojuG starting at 42:40.