SHARE ON:

Link copied!

The shipping industry, among other sectors, is supporting actions against climate change. In order to compensate for the increasing transport volume of maritime trade, transport efficiency in terms of CO2 emissions must be increased. Therefore, legislators are introducing regulations that must be complied with by both shipowners and operators. In addition to energy-saving equipment and low-emission fuels, there is a strong focus on the development of hybrid and electric propulsion systems for ships. Such solutions not only reduce the carbon intensity of the vessel, but also translate into higher efficiency and thus lower fuel costs.

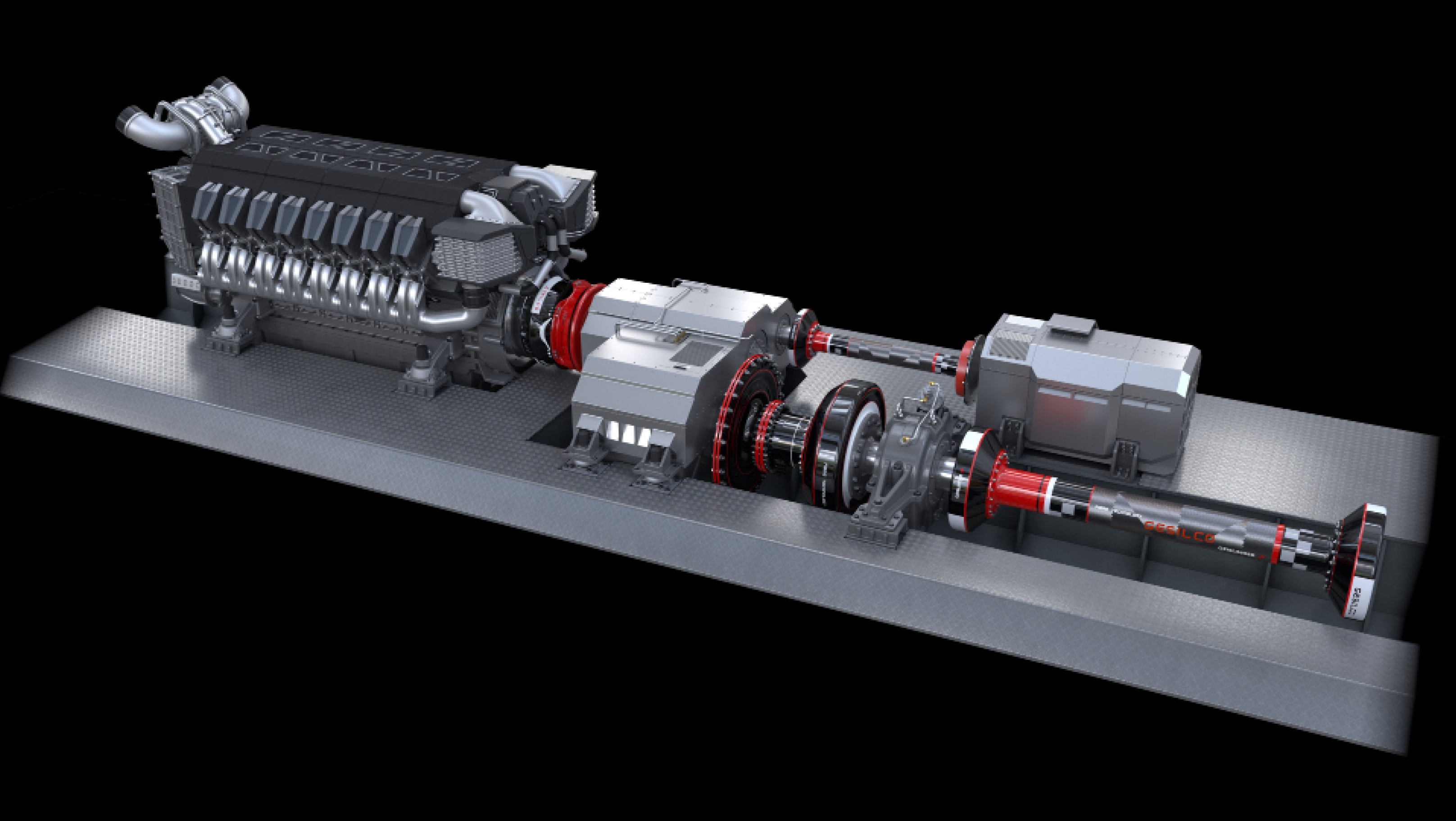

Hybrid propulsion is often closely related to the integration of zero-emission energy sources such as batteries or hydrogen fuel cells. However, naval architects and shipyards need to take energy conversion and power transmission into account as well. Geislinger sees itself as a key component supplier for the latter and strives to provide the ideal mechanical solution for modern marine drivetrains.

Selecting suitable driveline components, especially for complex powertrains, can be difficult. Each prime mover, whether a combustion engine or an electric motor, has its own characteristics that must be considered. Systems with a four-stroke diesel engine require closer attention to torsional vibration, while electric drives require proper insulation and lightweight coupling solutions with low moment of inertia. Geislinger, with its experience in ship propulsion systems, is committed to providing products and expertise to meet all those powertrain requirements.

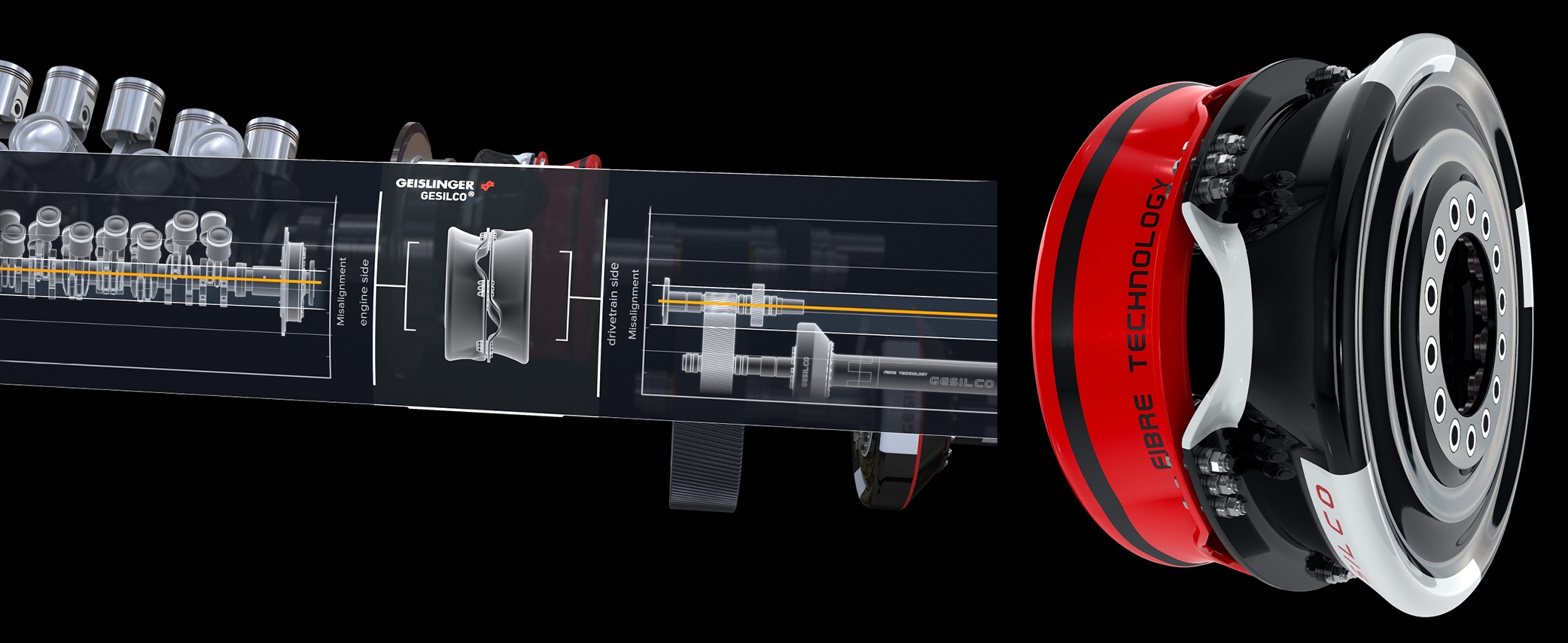

The GESILCO® product line is a viable solution for integrating electric drives into a powertrain. The fibre composite membranes feature outstanding misalignment capabilities while providing very low mass and moment of inertia. Optionally, any GESILCO® coupling can be delivered as a non-conductive component preventing dangerous current flow towards coupled equipment. In addition to the customized design, GESILCO® couplings come in various sizes and shapes.

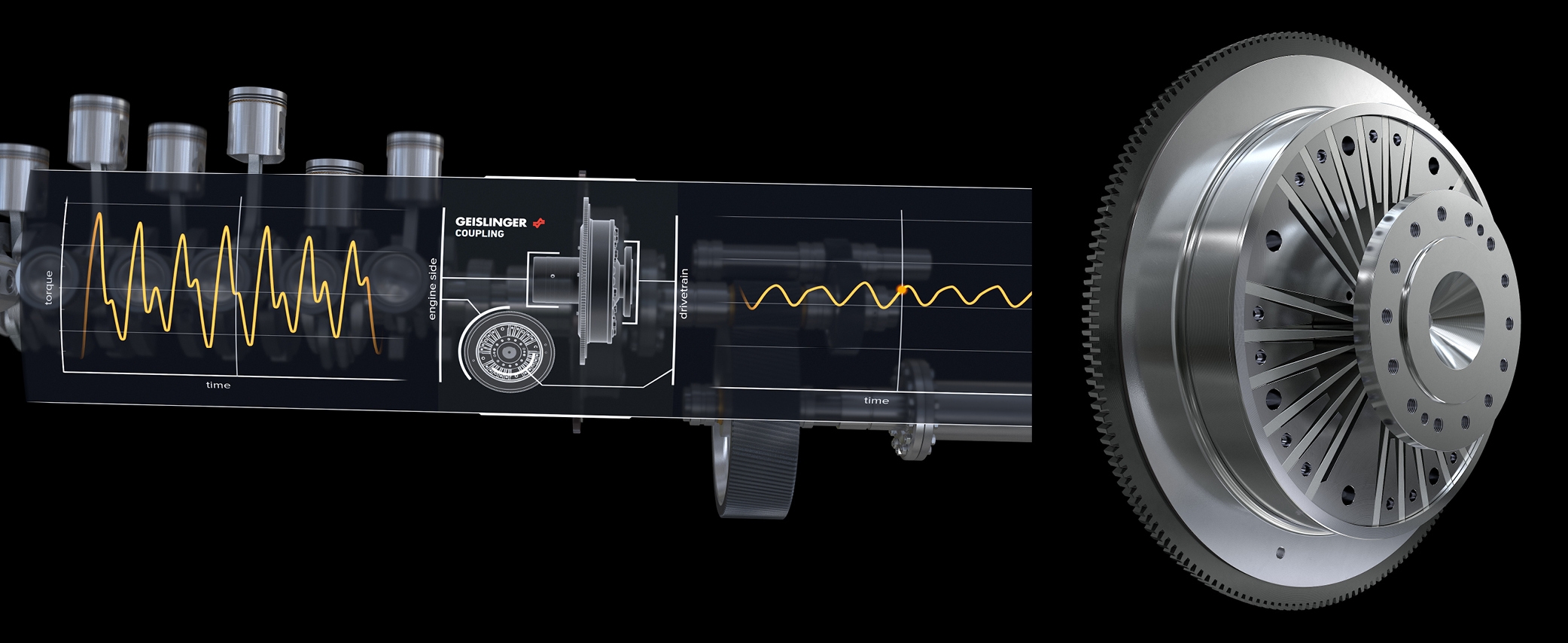

The Geislinger Coupling and its torsional elasticity, on the other hand, provide stability in mechanical hybrids by having a high damping coefficient. Resonances may occur when combining variable-frequency drives and combustion engines. In some cases, this interaction poses a threat to the driveline and must therefore be taken care of. Adding a Geislinger coupling to the driveline is an appropriate countermeasure, as it shifts resonance frequencies into a non-significant range and provides adequate damping in the areas that may be affected.

With the increasing complexity of modern powertrains, the monitoring of driveline components is becoming more and more important. The Geislinger Monitoring System Mk 6 is a solution that not only provides monitoring of key components such as couplings and dampers, but also monitors the proper operation of the powertrain in any situation. The data from the powertrain is then processed and anomalies in operation are quickly displayed in the Geislinger Analytics Platform.

With a broad portfolio of powertrain solutions, Geislinger is well prepared for the upcoming challenges in the marine sector and especially hybrid marine powertrains. The Electric and Hybrid Marine Expo was an outstanding event to showcase Geislinger’s solutions to an interested audience. We are very much looking forward to participating in the exhibition again next year.