SHARE ON:

Link copied!

With more than 60 years of experience in dealing with torsional vibrations in complex powertrain systems and 30 years of experience with monitoring systems, the latest generation of Geislinger's Mk6 monitoring system is the newest gateway to the digital world of torsional vibration monitoring. The Geislinger Monitoring System allows for torsional vibration and power monitoring of the powertrain. In combination with the Geislinger Analytics Platform - a revolutionary, machine-learning, in-house software, utilizing big data analysis - the simulation and visualization of key performance indicators of the powertrain and, most importantly, early fault detection, is enabled.

With the Mk6 it is possible to continuously push operational data into the Geislinger Analytics Platform. The Geislinger Analytics Platform (GAP) is a cloud-based online monitoring platform for torsional vibration and permanent measurement that enables predictive analysis and anomaly detection. The vibration monitoring system can be accessed remotely at any time via a computer or mobile device. A clear and optimized web interface for PC or mobile devices allows customers to access both the Geislinger Monitoring System and the Geislinger Analytics Platform at any time.

Based on experience with the previous generation, the new capabilities of the Geislinger Mk6 and online services help CPO and its crews operate vessels within the most efficient parameters. This increases operational safety, reduces emissions and wear and tear on key components. Inferences about wear and tear are among the pilot project’s most valuable information. In addition, data analytics allows maintenance and servicing activities to be scheduled in advance and carried out more efficiently.

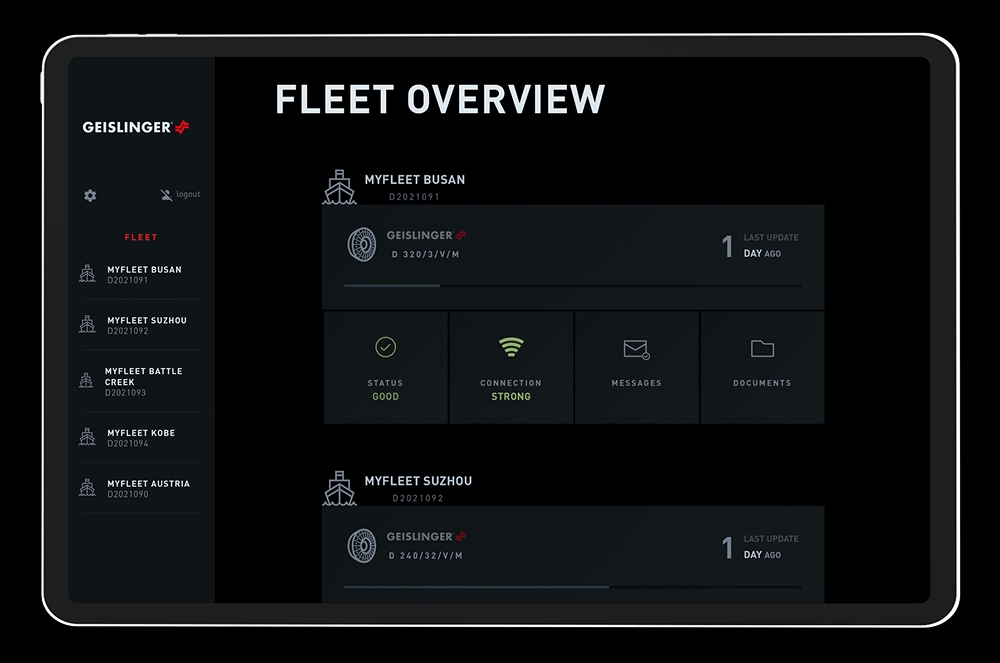

Overview of the fleet

With the Geislinger Analytics Platform, CPO can effortlessly track and compare the performance of the individual vessels in its fleet. Best practices can be shared, and crews across the fleet are able to receive real-time support. Software updates, remote service and document management are other benefits implemented in the platform.

Important next step towards digitalization

"The more than pleasing results of the pilot project confirm what digitalization can achieve in the marine industry", says Christoph Gessner, COO of CPO. "We are proud that the pioneering role is paying off." Geislinger is confident that the pilot project with CPO has set an important milestone with its digital services. "Demand for powertrain digitalization is currently growing, and we are proud to have a partner like CPO on board", says Torsten Philipp, Managing Director of Geislinger GmbH.

CPO and Geislinger will continue their close cooperation and work on additional features and enhanced real-time performance monitoring.