SHARE ON:

Link copied!

The US Department of Energy has partnered with industry professionals in the Supertruck 2 program to develop new technologies and engine developments to support the initiatives mentioned above. Companies like Daimler, Volvo, Cummins/Peterbuilt, Navistar and DAF/PACCAR are involved with development focus on vehicle and engine efficiency optimization.

The parameters set forth by the Government meant that engine manufacturers and industry partners were going to have to look at unique methods to meet these new demands. Geislinger is a well-known industry partner for providing customized solutions for the most challenging environments and parameters. Due to this reputation, Geislinger was asked to develop a crankshaft damper for a high-efficiency prototype engine of the Supertruck 2 program.

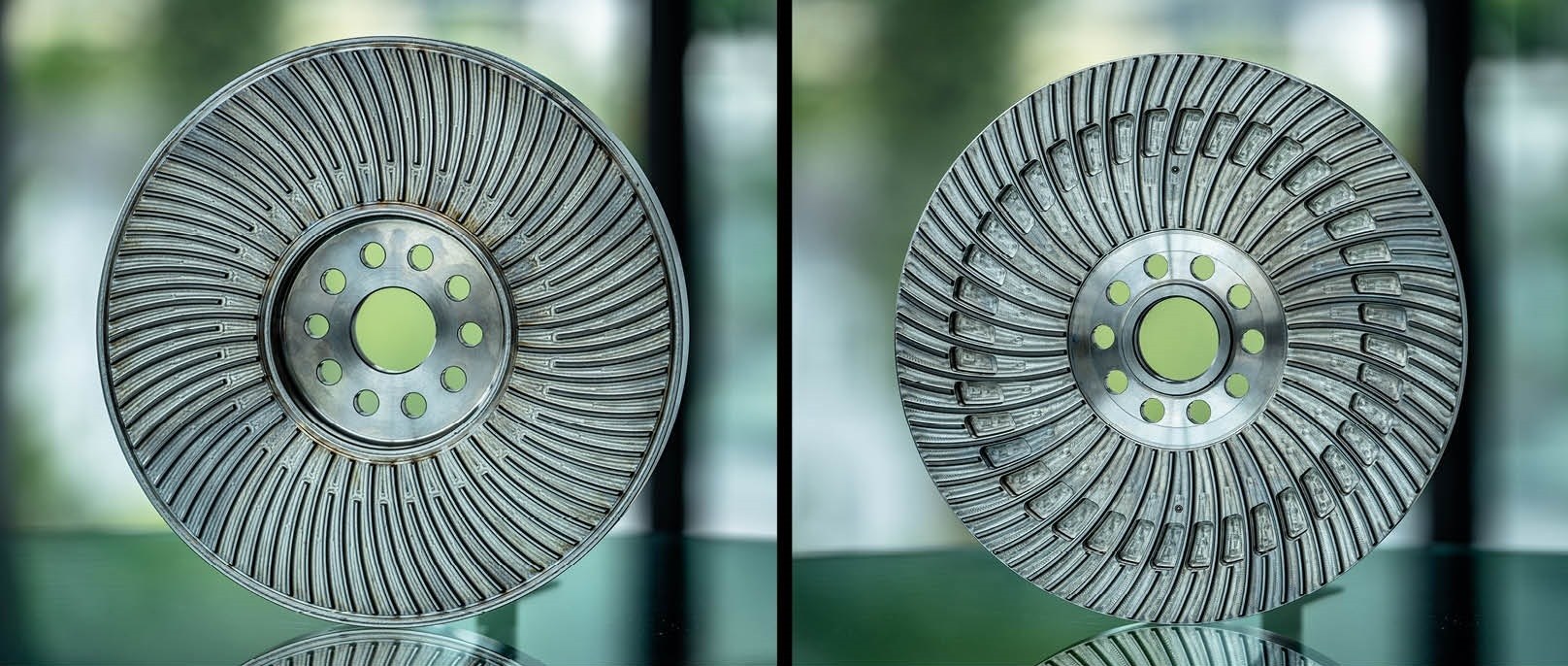

One of the initial challenges when looking at the viscous damper were the temperatures inside the engine cover and the heat generated by the viscous damper. The Geislinger Vdamp® is filled with a silicon fluid with fins added to the surfaces to increase the flow of air around the damper. The increased air flow allows for a greater heat dissipation around the damper and ensures maximum thermal stability. For each single application, Geislinger sets up a computer model – a so-called digital twin – of the complete powertrain, which covers all relevant boundary conditions and operating profiles in order to develop the most efficient solution.

During our analysis, we found that at the operating speed required for the system the damper still had a high thermal load and so the development began for a completely new viscous damper design. This new innovative design incorporates fins into the housing that allows additional cooling for the Vdamp® so that a remarkably high heat dissipation can be achieved during operation. With this new and highly optimized viscous damper, Geislinger was able to meet the torsional requirements for the system while keeping thermal stability at a high level.

As a world leader in providing powertrain solutions, Geislinger has the in-house expertise to engineer customized solutions for the most demanding applications and requirements. Geislinger Powertrain Solutions – Engineered for Performance and Built To Last!