SHARE ON:

Link copied!

The Blohm+Voss powerplant in Hamburg is taking a leap forward in both efficiency and monitoring capabilities. Geislinger Digital Solutions is supporting the process. Due to the need for a new damper, the dual-fuel (Diesel + gas) facility has been upgraded not only mechanically but also digitally—with the installation of the state-of-the-art Geislinger Monitoring System.

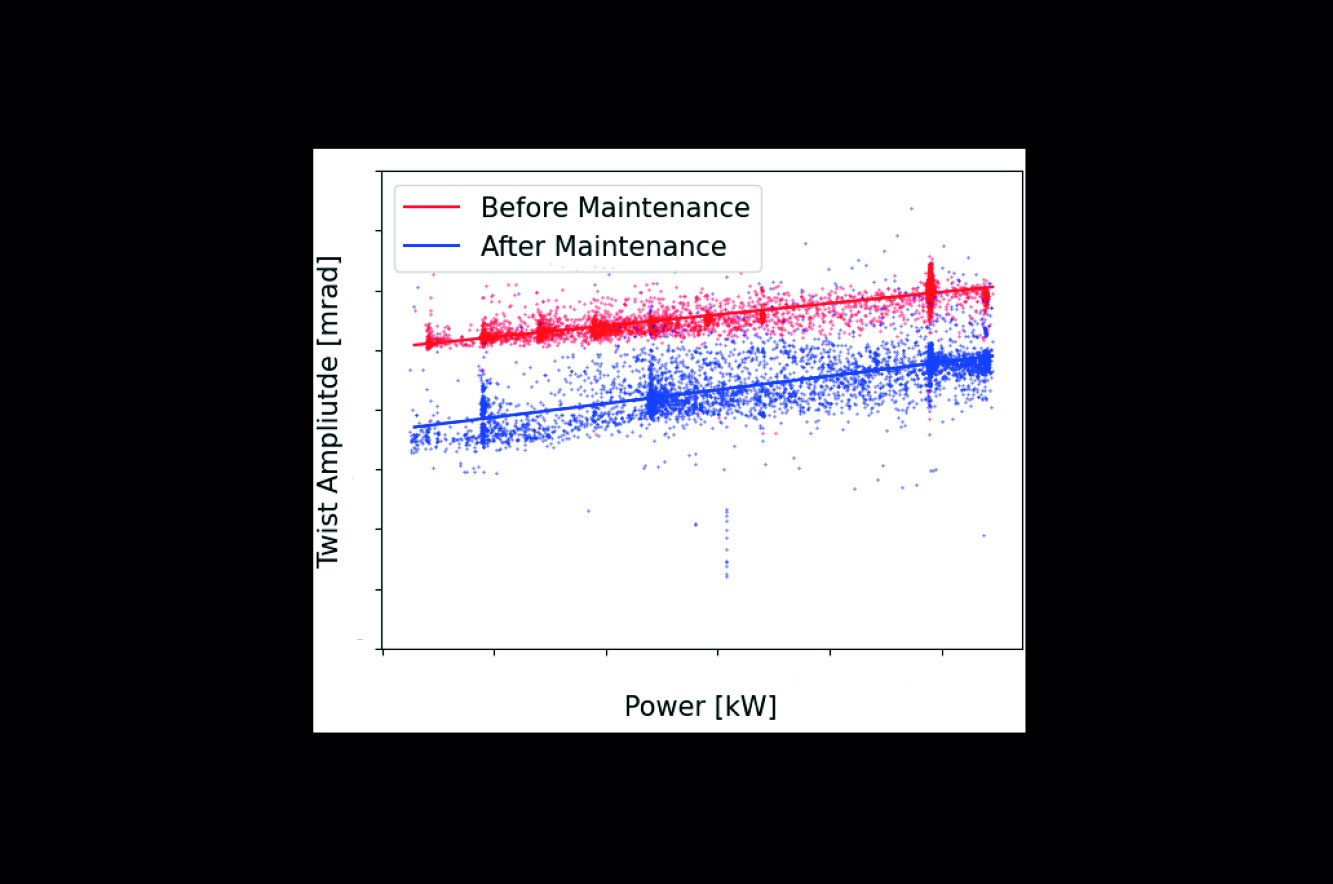

During a major engine maintenance, the Geislinger damper was replaced as well. After the maintenance, a significant reduction in torsional vibration amplitudes for the same average load can be clearly seen. Following the replacement, the system now operates more consistently within its defined limits. The damper is performing as expected, effectively protecting the system from overloads caused by torsional vibrations. The observed change in damper behavior is in line with expectations and can be attributed to its renewed state, free from wear and degradation.

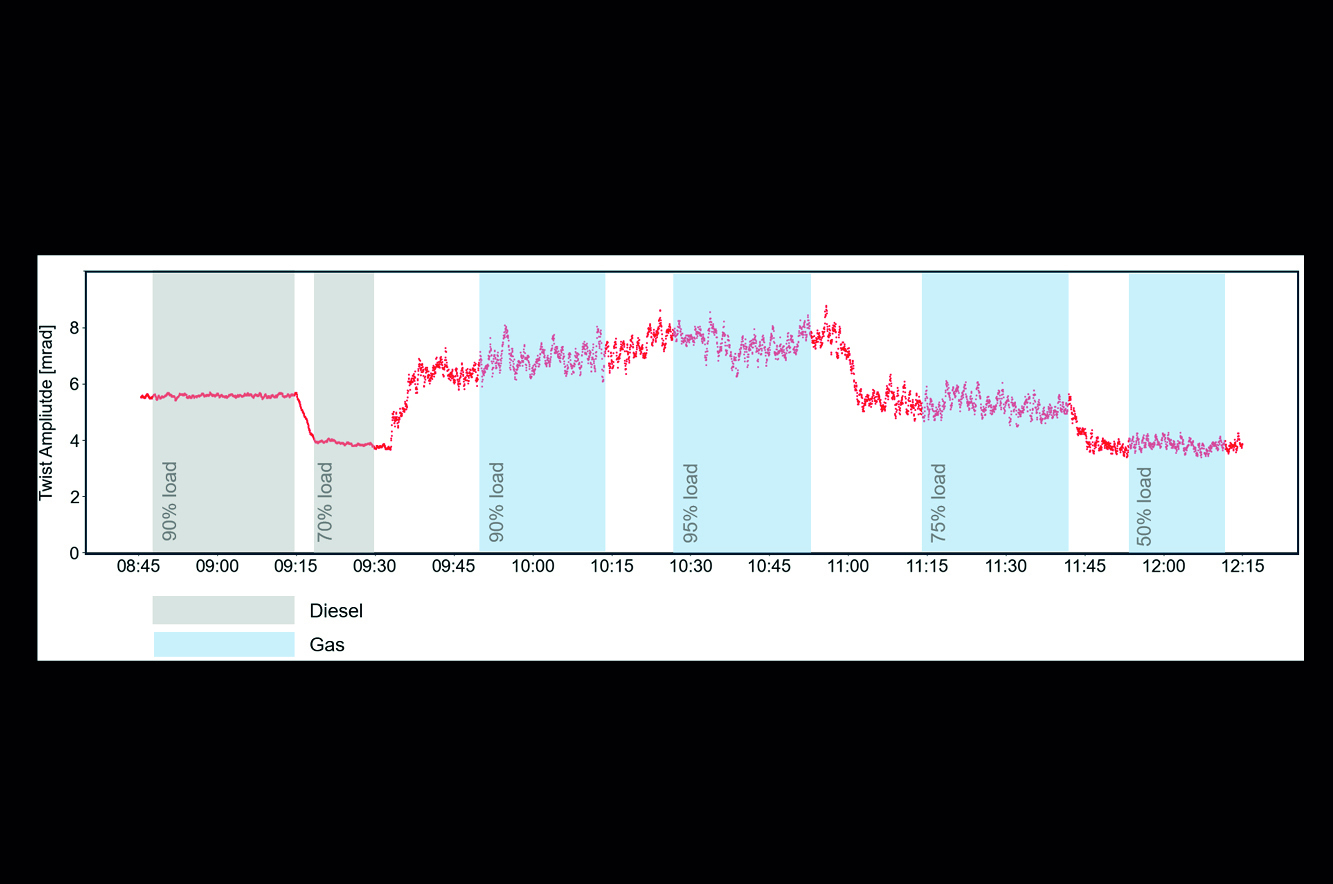

A few weeks after the engine mainanance, load tests were carried out with different fuels. This involved testing how the system behaves when running in Diesel mode and gas mode under different loads. Picture 2 shows the different operation modes and load configurations and the corresponding twist amplitude. The load cases are clearly reflected in the twist amplitude levels, with a surprisingly large variance in the signal observed during gas mode operation.

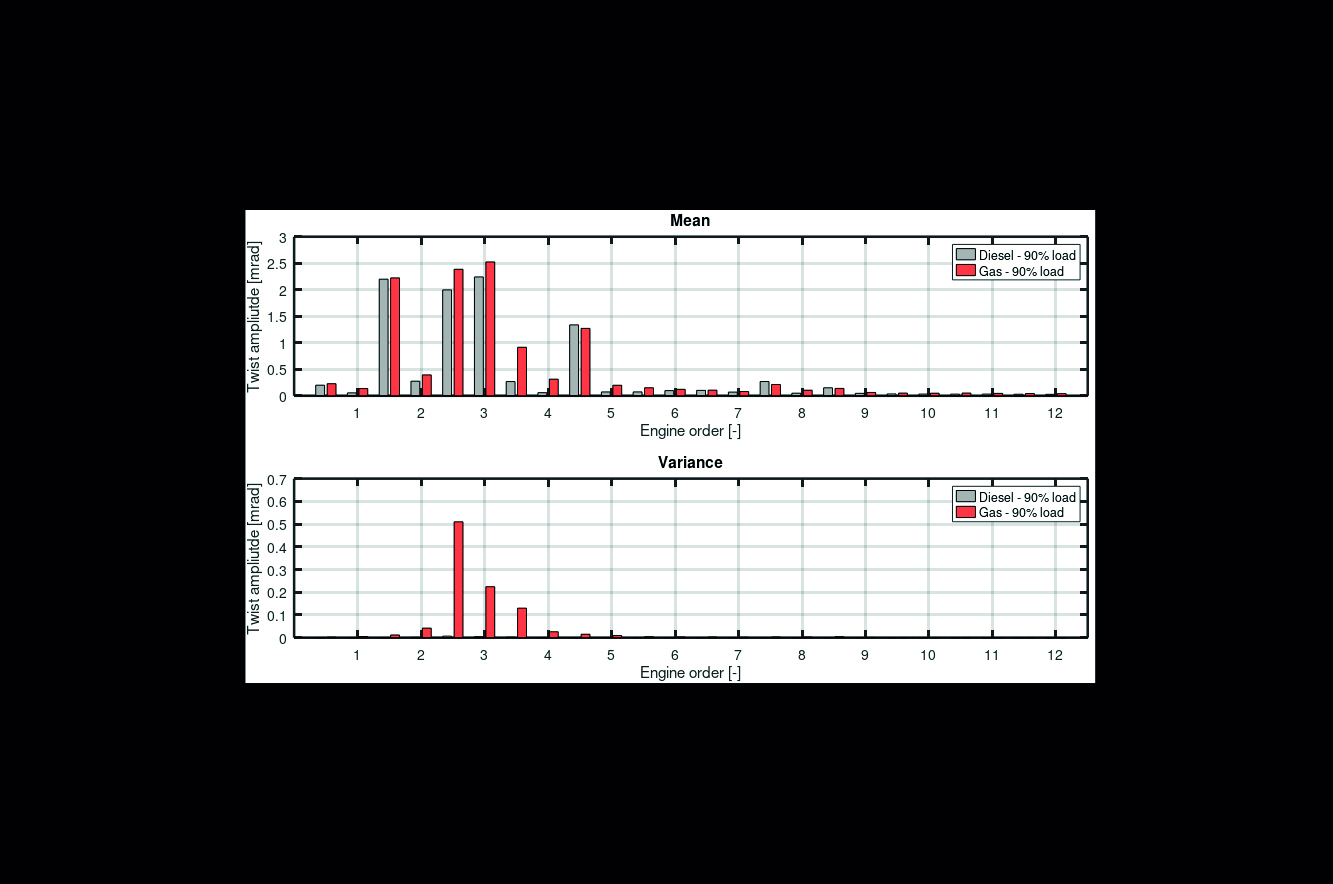

The quantitative analysis (picture 3) reveals that the twist amplitudes closely align with the values predicted by the torsional vibration calculations. The means for Diesel and gas mode loads show minor differences.

In contrast, the variance observed during gas combustion is approximately 100 times greater than that of Diesel combustion. This measured variance exceeds expectations and may be attributed to the quality of the gas or other influencing operating parameters. (The increased variance indicates a higher load on the engine and the damper. The Geislinger system can therefore provide valuable information for early detection and maintenance measures.)

Flexible maintenance intervals

Permanent monitoring starting with the very beginning of the operation will not only lead to guidance and indications for performance optimization with different fuels but also has the potential to benefit the operator with savings for maintenance. Instead of fixed intervals we switch to flexible intervals with maintenance indication in advance for planning, the possibility to align the maintenance job with other components and – last but certainly not least – the potential to extend the intervals and thus achieve savings.

Gas Quality

As previously observed, the signal exhibits significant scatter. This variability may differ between gas supplies, potentially offering insights into the properties and consistency of the gas being used.

That is not all, sharing means caring: A smart interface now allows data from partner company Schaller to be pushed directly into the Geislinger cloud infrastructure. The result: all critical operating data is accessible through a single user interface, enabling direct comparison of Geislinger and Schaller measurements and providing valuable insights for optimized performance. Additional data integration is foreseen shortly.

The upgrade of the Blohm+Voss power station in Hamburg demonstrates how a combination of mechanical renewal and intelligent digital monitoring can significantly improve operational efficiency, reliability, and insight. By installing a new damper and integrating the Geislinger monitoring system with Schaller's data stream, Blohm+Voss has taken a proactive step towards future-proofing its operations.

We invite you to visit with us the Blohm+Voss Powerplant in Hamburg on-site and experience these innovations firsthand—see how advanced engineering and digital solutions work together to optimize real-world powerplant operations.

And this is just the beginning – stay tuned for even more new features of the Geislinger Monitoring System that are set to redefine the standards of reliability and efficiency, and performance. Read about the latest innovations in our upcoming blogposts.