SHARE ON:

Link copied!

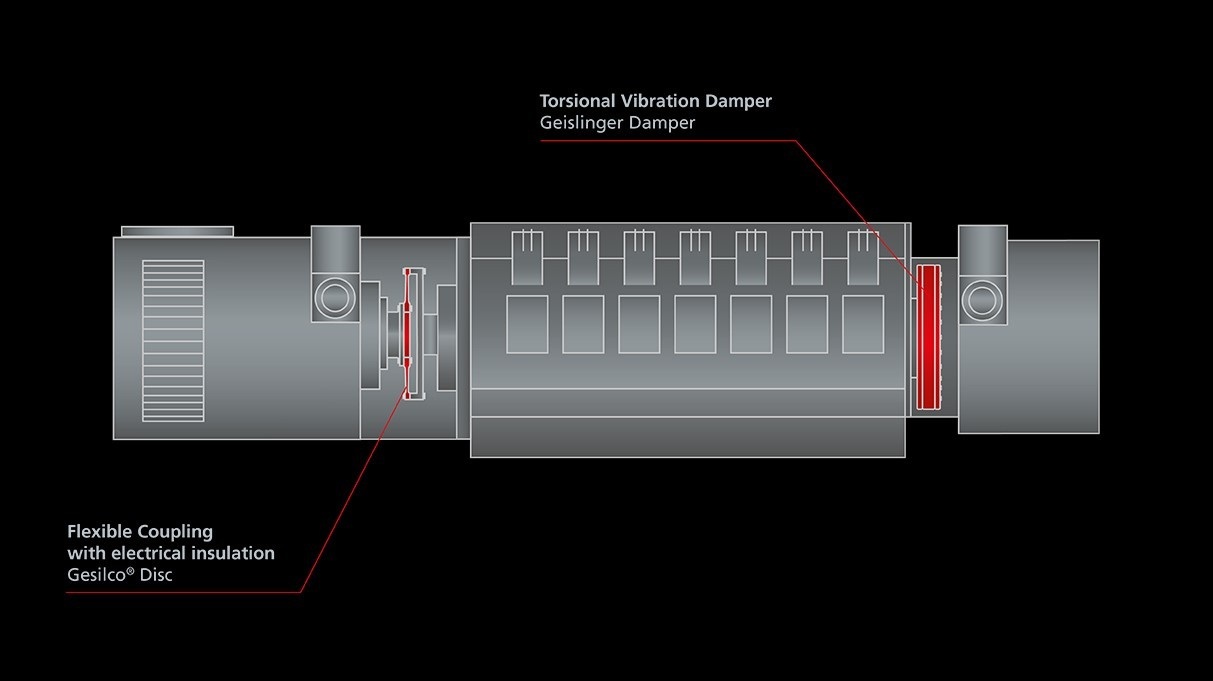

This application shows an example of a diesel-electric power pack with a closed coupled single bearing alternator for an underfloor rail application. The reciprocating engine is connected to the alternator by the Gesilco® Disc, which is made of composite materials. The Gesilco® Disc coupling is flexible in axial and angular direction. It significantly reduces the restoring forces in the bearing. Additionally, the fibre composite coupling protects the engine due to its electric insulation and non-magnetic properties. The Geislinger Damper with its compact design is integrated into the crankshaft and lubrication oil system. The spring steel damper enables the genset to be operated at variable engine speeds in hot ambient conditions up to the full engine lifetime.

To summarize, the maintenance-free Geislinger Gesilco® Disc coupling in combination with the Geislinger Damper are key components for a highly compact and robust crankshaft and alternator design. Additionally, Geislinger offers integrated, compact and heat resistant torsional elastic couplings for all kind of genset applications for highest power density and lowest best life-cycle cost.

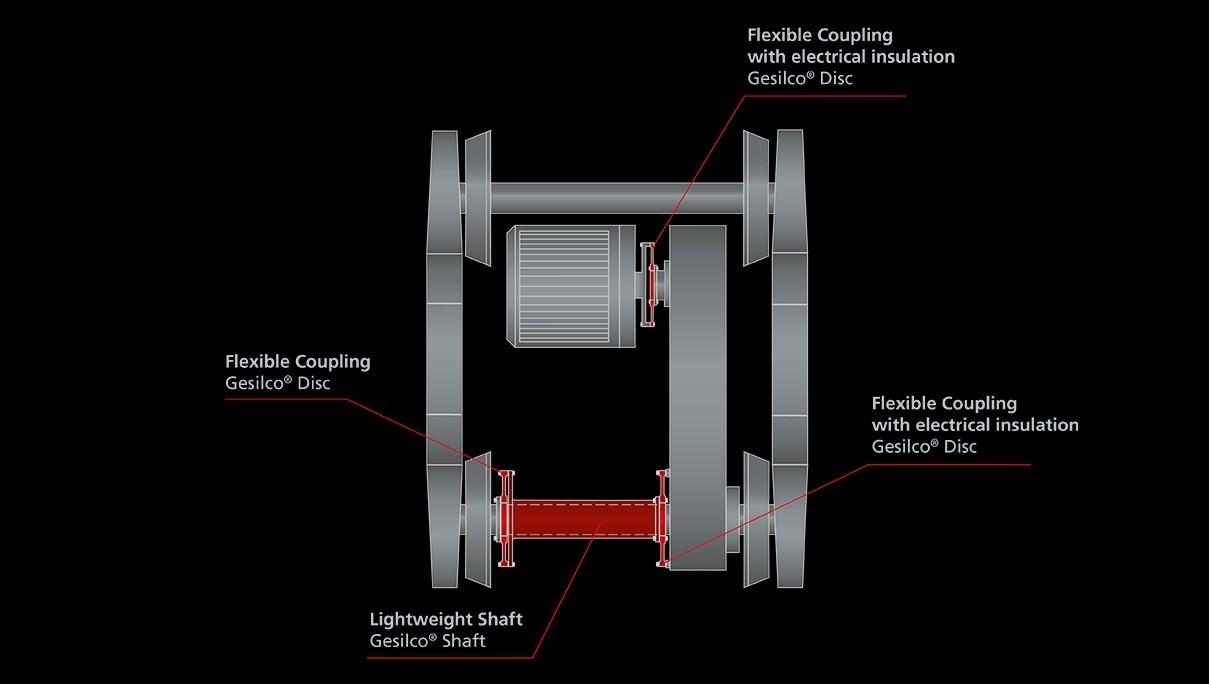

In the application example above you can see an electric motor for rail traction. The Gesilco® Disc membrane coupling is used in rail drives between the electric motor and the gearbox. The electrically insulating membrane is built for the highest load requirements, where a directly connected high speed electric motor drives the gearbox input shaft. The integrated e-motor flange design of this membrane coupling gives the possibility of an integrated overload function and eliminates possible high frequency currents and leakage currents. As an additional option, lightweight composite shafts can be integrated into the system, as shown in the picture above.

Applications with full shock absorbing e-motor concepts are individual designs where flexible composite materials transmit the highest torques and insulate the gear from a possible leakage current. A compact product design with electrically insulating properties is the decisive factor for rail applications. Geislinger provides customized and reliable solutions and is prepared for innovative drive systems.