SHARE ON:

Link copied!

The monitoring system is the gate-opener to the digital world. Geislinger Digital Services combine 60 years of torsional vibration calculation and engineering know-how with 30 years of vibration monitoring experience and now with artificial intelligence solutions enabled via the Geislinger Analytics Platform.

The Geislinger monitoring system is designed for monitoring torsional vibrations within the whole powertain and predict failures through early detection of abnormal behaviour. The used hardware components guarantee a high level of robustness against harsh environmental conditions, for example in industrial applications. However, due to the modular design the Geislinger GMSMk6 allows for tailor-made solutions for almost all powertrain components and can therefore be used in a wide range of applications, such as marine propulsion, power generation, wind power, rail applications, compressors or test beds.

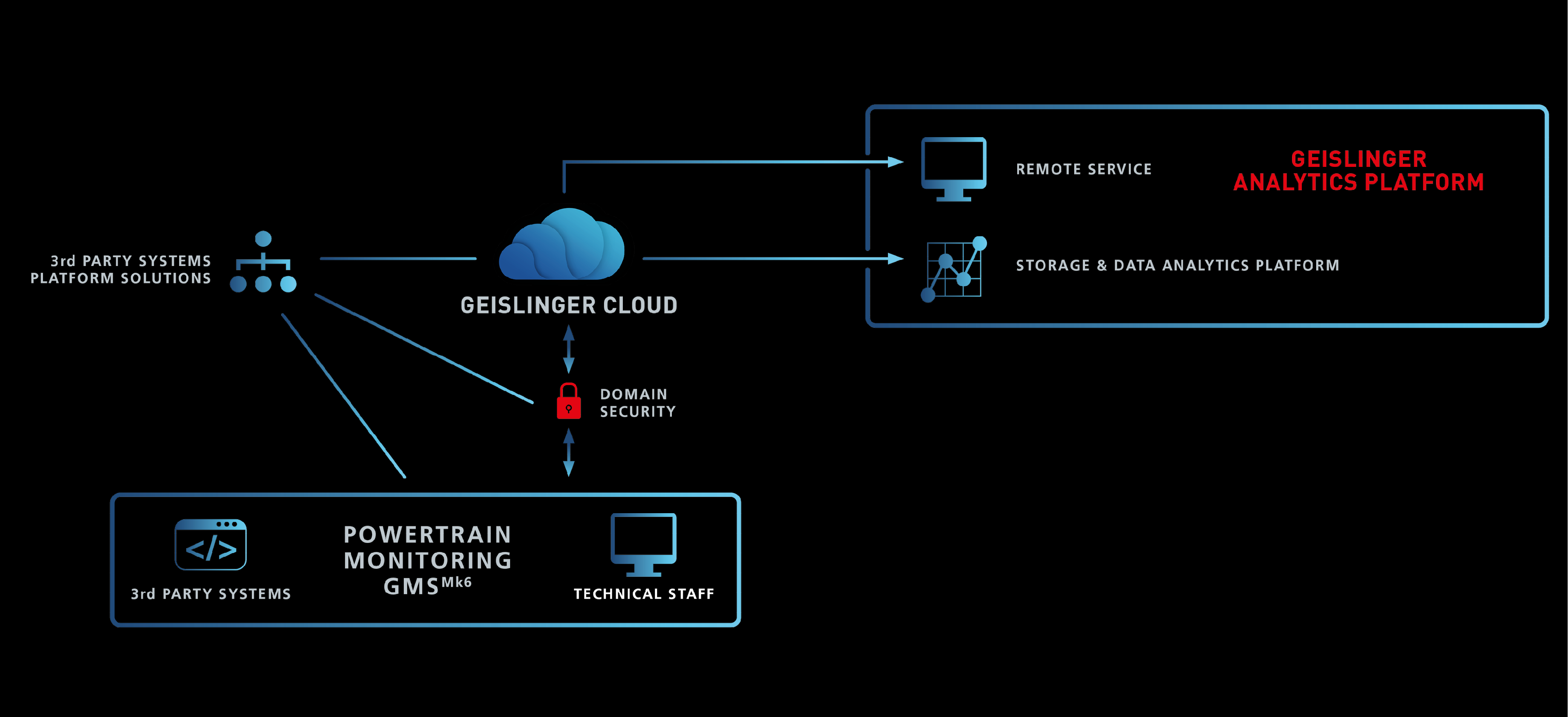

The Geislinger Analytics Platform is a cloud-based online monitoring platform for torsional vibrations and permanent measurements allowing for predictive analysis and anomaly detections. It provides an interactive and intuitive dashboard solution, which facilitates also a fleet management dashboard by giving you an overview of all important and relevant information.

The cloud is entirely hosted by Geislinger and maximum data security is guaranteed. By using the Analytics Platform, a trend analysis can be made, which offers an in-depth look into the system and allows for recommendations to run systems more efficiently, which leads to an increased service life due to problems being detected early. Based on the gathered data a report on the condition of the system is created. The continuous measurement of the powertrain as well as the automated analysis of the measured data are used to improve our simulations. With this additional data, the simulated “Digital Twin” of the measured system becomes even more accurate. And this gives the Geislinger Engineers the option for very accurate predictive and condition-based maintenance advices. Due to the direct line to Geislinger services, experts are able to access the monitoring system remotely and investigate the monitored torsional vibrations to minimize the downtime of a system and reduce operational risks.

Geislinger Digital Services are your connection to the future of innovative powertrain solutions!