SHARE ON:

Link copied!

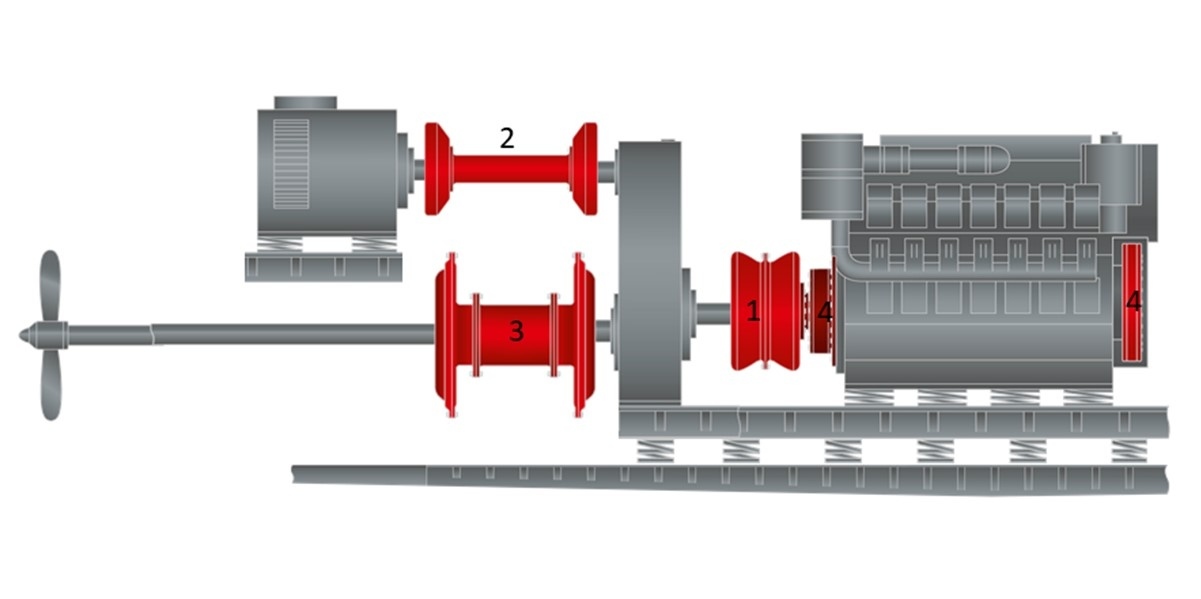

Our Gesilco® Coupling was the first one of its kind made from fibre composites for marine applications. At Geislinger, we believe that the secret to creating the best product solution for our customers is to precisely design and craft every key element. Looking at ship applications, the Gesilco® product family can be used for almost any requirement. As an example, figure 1 shows a typical powertrain in a high-performance mega yacht:

1) As you can see in Figure 1, the Gesilco® Butterfly Couplings are often used as a lightweight misalignment coupling solution between the engine and the gearbox (see number 1). They are known for their lowest reaction forces, are maintenance free and can be acoustically optimized.

2) Modern yachts are often built with a hybrid propulsion including a power take in (PTI) or a power take off (PTO). These electric generators or engines can easily be integrated using Gesilco® Monobrane Couplings with a Gesilco® Shaft in between them (see number 2). The length of the lightweight shaft can be varied over a wide range depending on customer needs. As an alternative, a variant with brand new components of the modular Geislinger Silenco® Coupling can be used for the highest possible reduction of structure borne noise offering electrical insulation as an option.

3) In many applications, the coupling between the gearbox and the propeller shaft is the most critical connection (see number 3). The engine and gearbox are mounted with an elastic or double elastic frame against the ship’s structure, therefore a broad-band reduction in transferring structure borne noise is essential. The Geislinger Silenco® Coupling was originally designed for this application as it is able to do both: transmit the high torque and reduce the structure borne noise to non-critical values.

4) In addition to the Gesilco® products Geislinger offers its well-known steel spring couplings and dampers, minimizing the torsional vibrations of the engine itself (see number 4). Thus Geislinger is able to offer innovative solutions for all components in the power train.

Various innovative Gesilco® product solutions will be presented at the SMM 2018. Visit us at our booth, Hall A3, booth number A3.105 and celebrate with us 25 years of our Gesilco® product group. A highlight will be the presentation of a variant of the Geislinger Silenco® Acoustic Coupling.