SHARE ON:

Link copied!

The software of the GMS Mark5 is based on 25 years of experience monitoring torsional vibration dampers and couplings. It is continuously being developed further by in-house engineers and therefore based on the highest quality standards. The data recorded by the GMS can be evaluated by Geislinger experts in order to prevent damage to the system.

In order to ensure the correct performance of a system during operation and to facilitate a condition-based monitoring of the Geislinger products, Geislinger offers a monitoring system that has been developed and improved by our experts for more than 25 years. The Geislinger Monitoring System (GMS) is a continuous monitoring and measuring system for rotating components and is usually used in conjunction with Geislinger torsional vibration dampers and torsional elastic couplings. It is intended for use in a wide range of applications, such as marine propulsion, power generation, wind power, compressors, and in the oil and gas industry.

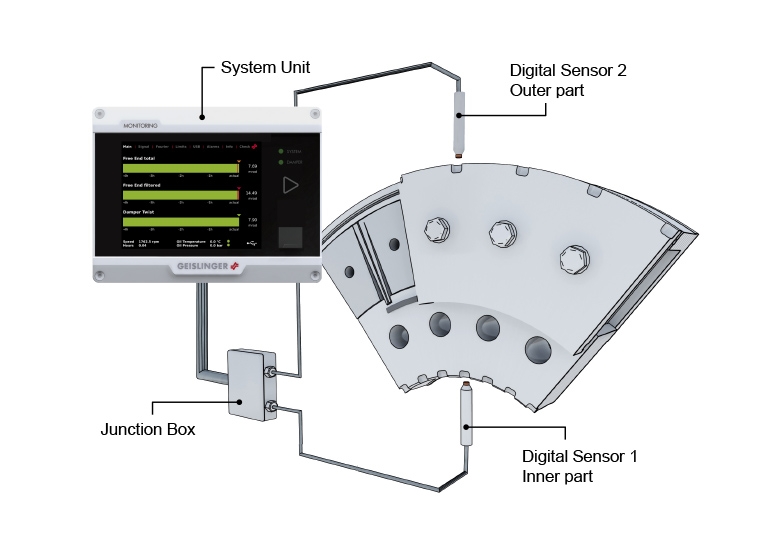

The standard Geislinger Monitoring consist of three main components:

- System Unit

- Junction Box

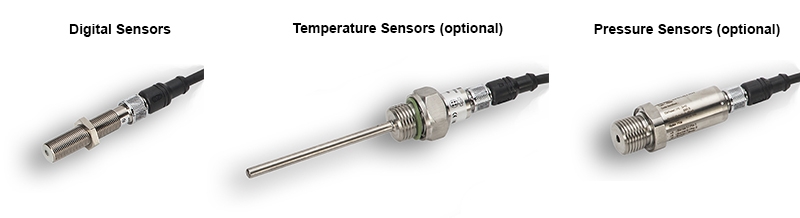

- Digital Sensors

Its main task is to monitor the components and recognize functional deviations. The system can also be used for measuring axial vibration, oil pressure, oil temperature, power monitoring and detecting misfiring. If the safety limits are exceeded, an alarm is triggered. This allows the users to take appropriate measures to prevent component or system failures. By detecting critical overloads, damage to the damper, coupling or other drive train components can be avoided.

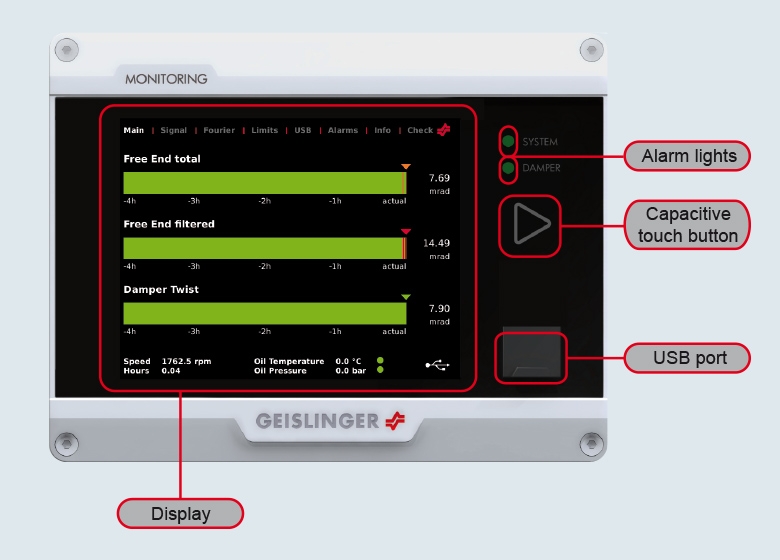

The GMS provides an easy-to-use USB interface for data acquisition. Intuitive operation by just pressing a single touch-button goes in-line with the robust design and guarantees reliable operation even under the roughest conditions. Furthermore, the Geislinger Monitoring System can be integrated into the ship’s network or the existing AMS.

Customers appreciate Geislinger’s in-house competence: with the help of the GMS internal data recording, Geislinger specialists can evaluate if the damper or coupling is functioning correctly and can easily provide a worldwide after sales service. The statement issued can be used as an official service document and is recognized by classification societies. Therefore, damage to the system and its components as well as an overhaul can be prevented.