SHARE ON:

Link copied!

With the adoption of Safety of Life at Sea, a maximum air-borne noise of 110 dB(A) engine noise became mandatory in July 2014. The increase of engine power over the past years has made it even more difficult to achieve this limit. Further regulations like limits for underwater noise levels are currently under discussion and will increase the noise reduction requirements even further.

In large diesel engines most of the engine noise stems from mechanical excitations rather than combustion noise. Torsional vibrations of the camshaft caused by excitations of the injection pump have been identified by engine manufactures as the most important source of mechanical noise. These torsional vibrations lead to a gear teeth impact in the gear train between crankshaft and camshaft. The generated energy is transferred through the camshaft bearings to the engine structure and radiates noise. This effect is more severe with long camshafts (9IL- and 20V-cylinder configurations) as more potential energy can be stored and released.

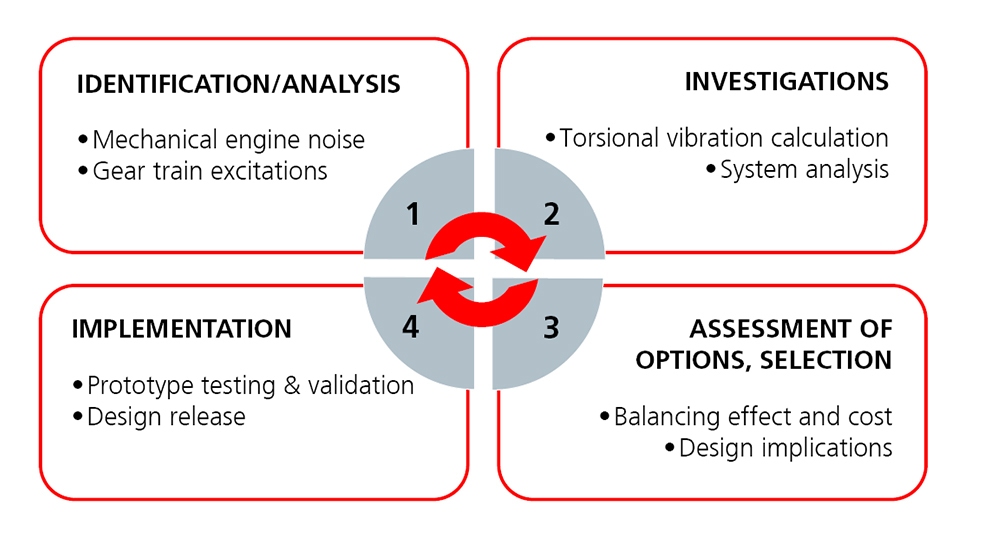

Acoustic tiles on the walls of the engine room and engine covers certainly reduce noise to meet these regulations. However, additional cost occurs, and engine covers complicate servicing work. Apart from just using isolation material, Geislinger powertrain solutions get down to the root of the problem. Excitations are being mitigated to avoid the formation of structure-borne sound instead of trying to reduce noise after it has been created. Based on more than 60 years of experience in torsional vibration technology, Geislinger has got the competence, the proper tools, and a wide range of products to tackle such problems as a powertrain solutions provider:

One option is the Geislinger damper, which is a tuned mass damper, widely used as crankshaft damper in large combustion engines. A Geislinger damper at the free end of the camshaft is a proven solution to reduce gear train excitations very close to its source. Another option, similar to the Geislinger damper is the Geislinger coupling, which is a highly integrated all-steel product with tuneable hydrodynamic damping.

For the purpose of illustrating the effectiveness of the gear integrated Geislinger Coupling, a 3D-multi-body simulation of the gear train of a combustion engine was carried out by the Austrian engineering heavyweight AVL on behalf of Geislinger. The pre-post study confirms that a Geislinger powertrain solution is effectively solving the problem at its origin, at the location of the excitations. For more information, please login here and download the full paper on the Geislinger Academy: Geislinger White Paper Engine Noise