SHARE ON:

Link copied!

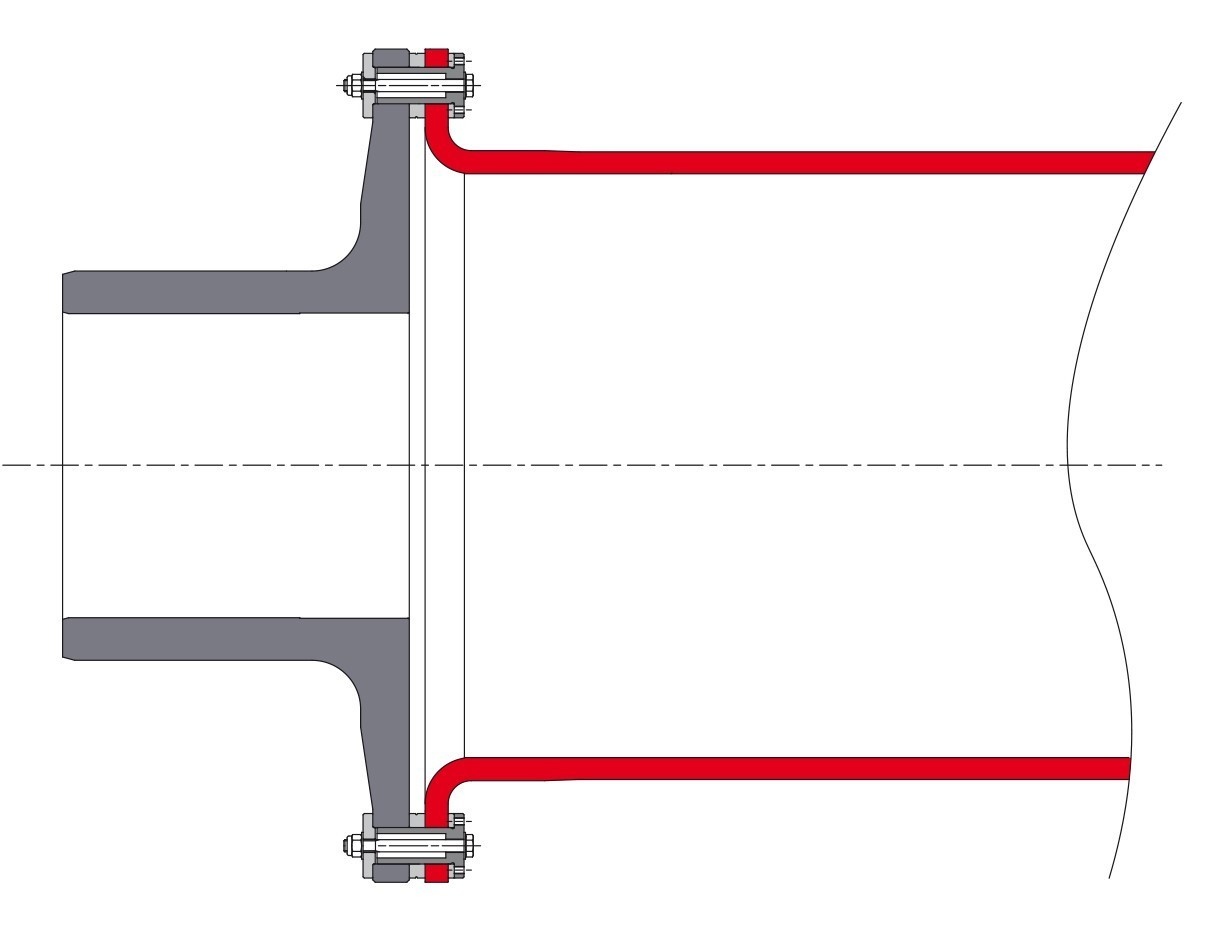

Geislinger utilizes the latest carbon fiber technology, machinery, and manufacturing processes to produce carbon fiber components. As Geislinger owns the complete manufacturing process along with a constant drive for innovation, many new designs have been developed and implemented. For instance, Geislinger produces its composite shaftline flanges completely out of carbon fiber. No steel components are required (see Figure 1). The molded flanges provide additional weight savings of 50% in comparison to shaftlines utilizing steel flanges.

In addition, for systems needing high dynamic misalignment, Geislinger provides shafting systems with composite misalignment couplings that allow for axial, radial, and angular movement during operation. Finally, Geislinger designs, manufactures, and tests all carbon fiber components in-house in Austria which provides the flexibility to design unique components around the needs and requirements of the vessel, and operator.

A recent project that is utilizing the Geislinger shafting system are two fast ferries that were designed by BMT. These vessels are currently being built by Nichols Brothers Boat Builders in Freeland, Washington. The propulsion arrangement required a unique shaft system with minimum weight.

Another project was for a fast ferry that is currently under construction at Mavrik Marine. The Geislinger system for this vessel incorporates two Gesilco® Misalignment Couplings that provide a high degree of dynamic misalignment for the system. In addition to the misalignment capabilities, Geislinger designed a single piece carbon fiber shaft that spans the over 5 meters length required for the installation.

Both projects show how the individually designed and lightweight shaftlines gives the customer new and innovative options that optimize their propulsion systems and save weight. With over 25 years of experience in producing carbon fiber components, Geislinger is able to design, manufacture, and deliver engineered solutions that meet the highest requirements for modern vessels.

We kindly invite you to visit the Geislinger Booth 3521 at the International Workboat Show in New Orleans, Louisiana December 4th - 6th. Geislinger will have a shaftline system on display along with engineers that will be able to answer and discuss any product or application questions that you may have.

Description