SHARE ON:

Link copied!

The noise level on the sea is constantly increasing. This has an impact not only on marine life and their environment, but also on the people who live or work in the port areas, as well as on the crew and passengers on board. For this reason, Vancouver has the EcoAction Program since 2017, which promotes ships with low noise emissions. Another project dedicated to the development of noise control measures is the NEPTUNES Project, which was established in 8 European ports, including Hamburg, as well as Canada and Australia. The goal of this project is to create standardized measurement protocols for determining noise emissions, which will enable classification and evaluation.

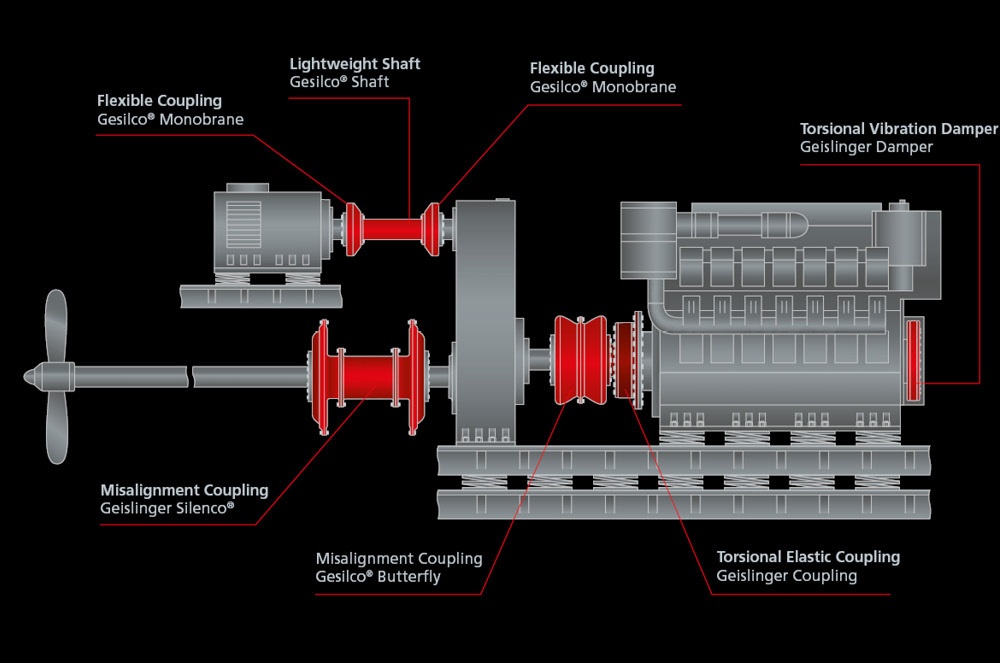

A large part of the noise emissions is caused by cavitation at the propeller. Below the critical speed of a ship at which cavitation starts, the noise is mainly carried out of the engine compartment by structure-borne noise. With Geislinger products, a reduction of the structure-borne noise is possible.

For optimum reduction of the transfer function, a combination of the torsionally flexible steel spring coupling and the fiber composite misalignment couplings of the Gesilco® series is recommended. This allows a broadband influence on the transmission path, as well as a large displacement potential in axial, radial and rotational directions.

With two unique test rigs, Geislinger is able to measure and evaluate the customized couplings. By adding force sensors, it is now possible to determine the impedance or dynamic stiffness of the components in the test rigs in addition to the transmission loss measurement of the acceleration. The dynamic stiffness reflects the characteristic properties of the respective coupling.

The current procedure includes in-house measurement and, if desired, measurement in the installed condition at the customer's site. Since a laser vibrometer is offered in addition to the transmission loss, a long measurement time at constant excitation is necessary. To shorten the measurement time, the acoustic properties should be precisely predicted by simulation.

Geislinger simulation model are constantly improved to simulate the modal analysis and harmonic analysis in such a way that the natural frequencies and transfer functions can be predicted with high accuracy and reproduced in subsequent measurements. In this context, a workflow has been worked out, which is now being tested on one product and will be extended to other Gesilco® products in the future.