SHARE ON:

Link copied!

The next generation onshore wind turbines not only need to be reliable but also silent. The latest developments show increasing rotor diameters with reduced rotational speeds and growing structures of drivetrains. As a result, less wind noise is generated. Due to this significant noise reduction, the tonal and annoying gear noise is no longer masked by the wind noise. Thus, new and more sophisticated solutions need to be put into consideration.

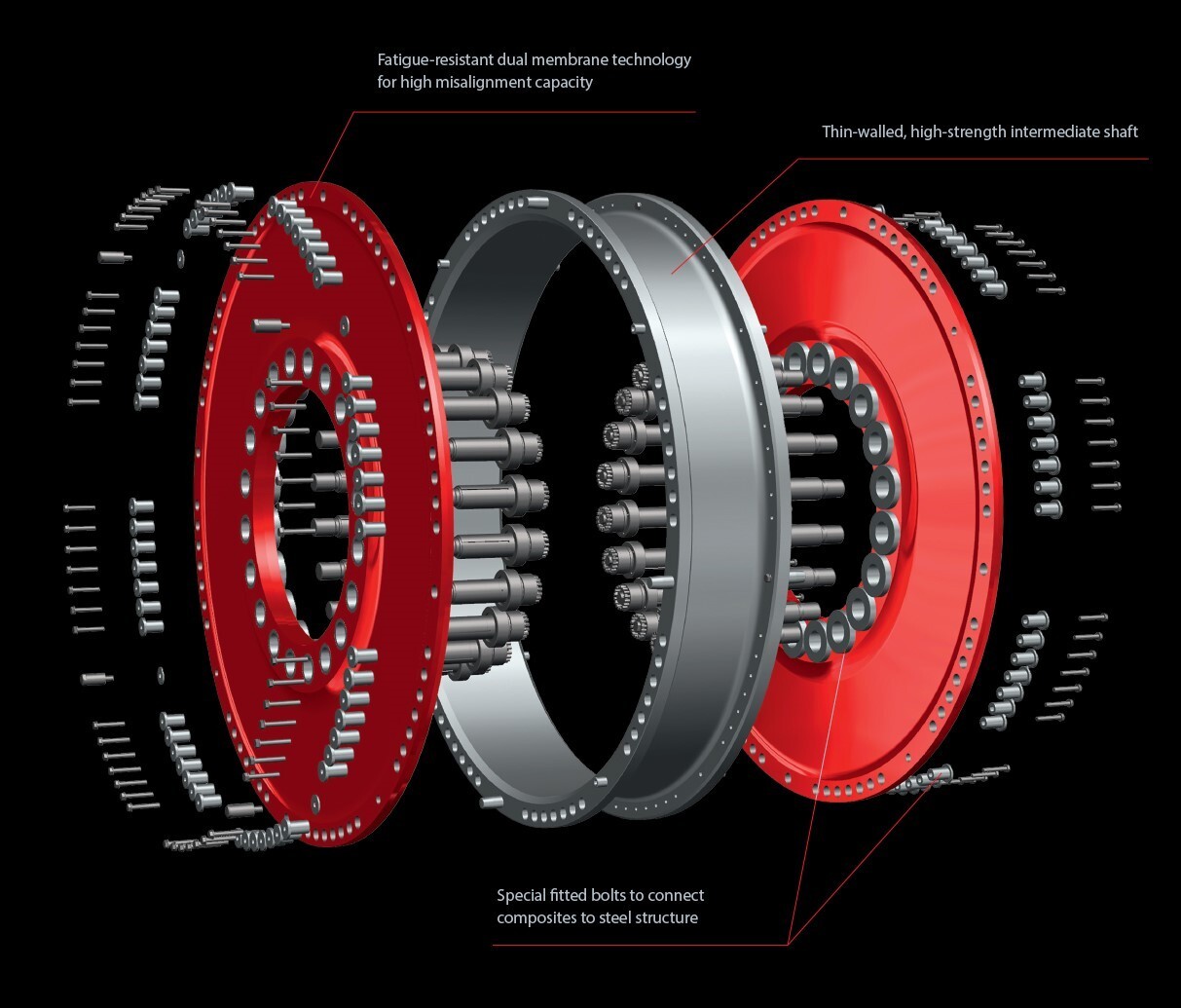

Geislinger offers tailor-made coupling and shaft solutions for various drivetrain systems. The Geislinger Compowind® Coupling for instance is ideally suited for medium- and high-speed wind turbines as well as for direct-drive technologies. Low reaction forces virtually eliminate non-torque loads and lead to a significant improvement in the dynamic drivetrain behavior. Moreover, Compowind® bears the potential to reduce wind turbine noise by attenuating the sound path from the gearbox to the rotor blades and to the tower.

The Geislinger Compowind® coupling is based on more than 25 years of experience in developing fatigue resistant, maintenance-free and weight-saving couplings and shaft lines. Compowind® protects the gearbox and the whole drivetrain by significantly reducing non-torque loads. It allows the gearbox to be rigidly attached to the main frame for which reason drivetrain bending eigenmodes are virtually eliminated and the dynamic behavior has been improved beyond comparison. This is not only important under severe load conditions and after the occurrence of special events, but also helps to achieve tonality free wind turbines.

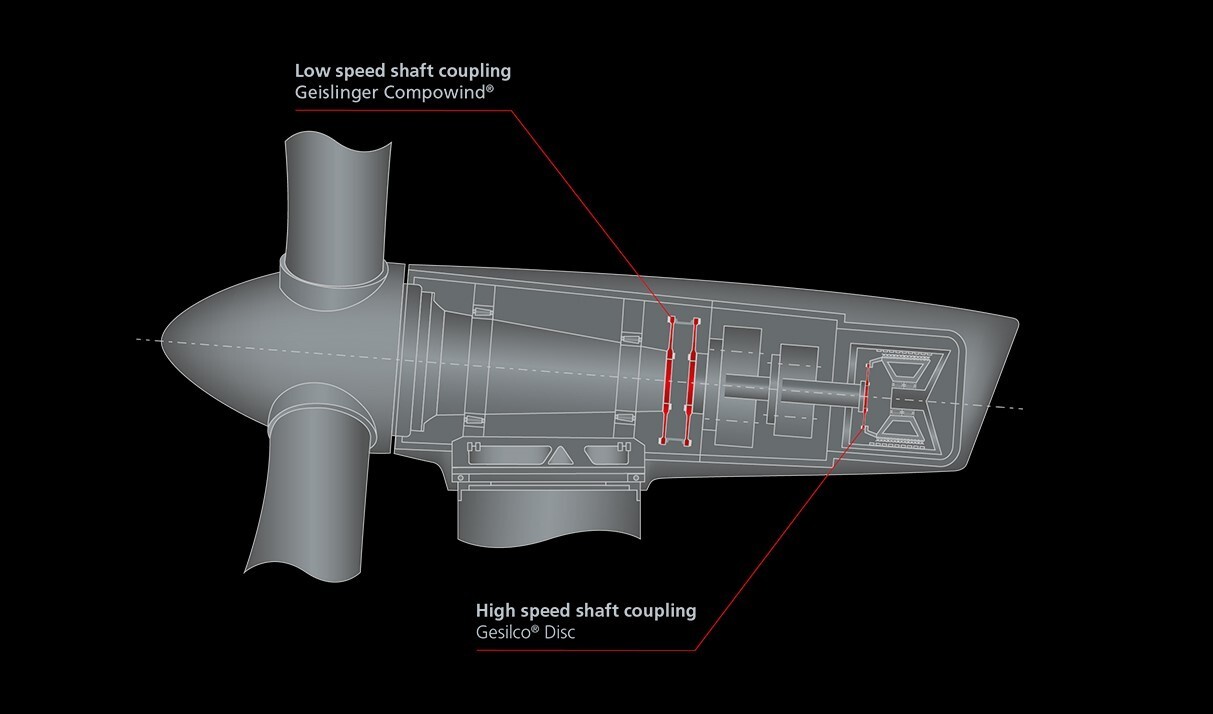

The comparatively low stiffness and the good damping properties of the Geislinger Compowind® reduce the sound transfer from the gearbox to the rotor blades, while the attenuation of eigenmodes helps to reduce sound propagation within the drivetrain in general. For this reason, the noise radiation from the rotor blades, the gearbox housing, the gearbox supports, and the tower is effectively reduced. This poses an additional customer value and a clear competitive advantage for onshore applications. See below the application example of an integrated medium speed drivetrain:

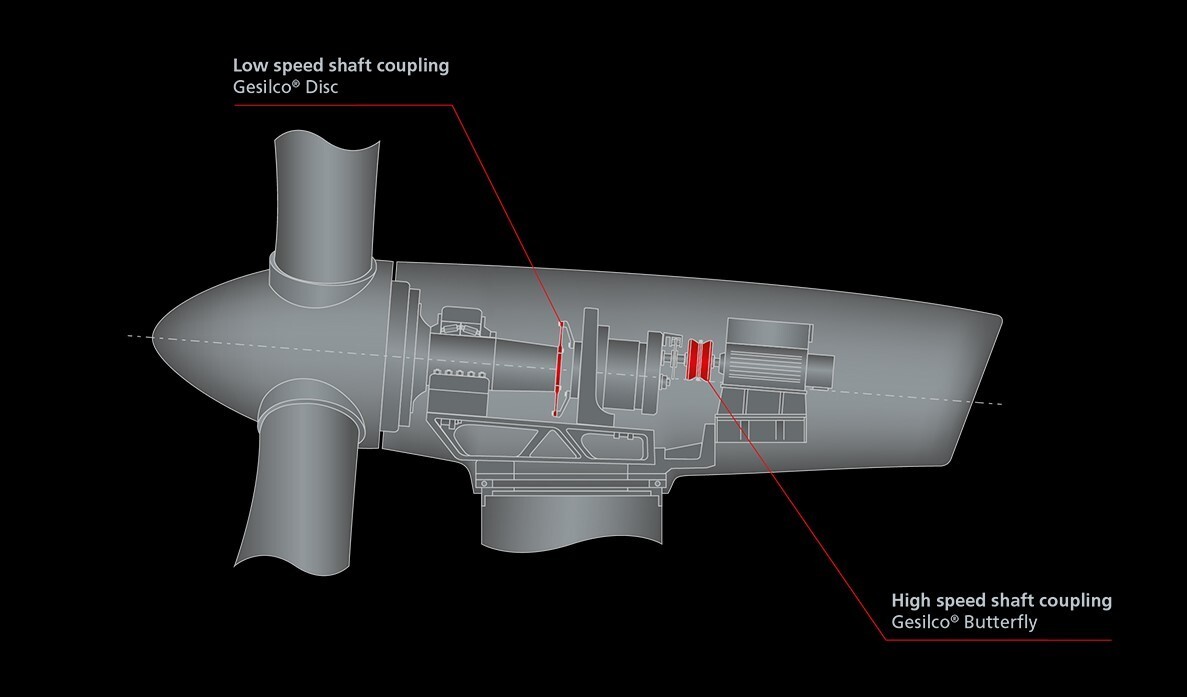

Besides the Geislinger Compowind® Coupling, other Geislinger products like the Gesilco® Disc or the Gesilco® Butterfly can also be used for wind drivetrain system.

The Gesilco® Disc is the ideal replacement for a steel coupling used in integrated medium speed drivetrains to couple the gearbox drive end to the rotor shaft. It is electrically isolating to avoid creepage current between the generator and the gearbox bearings. The flat membrane allows the transmission of high torsional vibratory torques and radial forces at high engine speeds. The Gesilco® Disc is also suitable to bear axial loads of a certain magnitude.

The membranes of the Gesilco® Butterfly coupling are made of lightweight and highly flexible composite materials in order to secure the lowest possible reaction forces, which increases the system’s reliability. As a replacement to a standard high-speed coupling in 3-point or 4-point supported drivetrains, a Gesilco® Butterfly reduces the distance between the gearbox and the generator. Shortening the length of the main frame and nacelle saves weight and cost.

Geislinger’s innovative coupling and shaft solutions give wind turbine producers a competitive lead in the race for weight, enhancement of reliability and reduction of operational cost (OPEX). Visit us at our booth number 5A21 at the Husum Wind 2019 and learn more about our customized solutions.

Download: Geislinger Application Guide Wind Power