SHARE ON:

Link copied!

CIMAC is the most important platform for discussions amongst the engine industry, technical experts and engine users. The 29th CIMAC World Congress took place from 10 – 14 June 2019 in Vancouver, Canada. This time, the focus was on the use of alternative fuels for reciprocating engines in terms of decarbonization and CO2 reduction. The engine operation findings on natural gas (CNG and LNG) and many other options such as methanol or ammonia as well as biofuel concepts were presented and discussed.

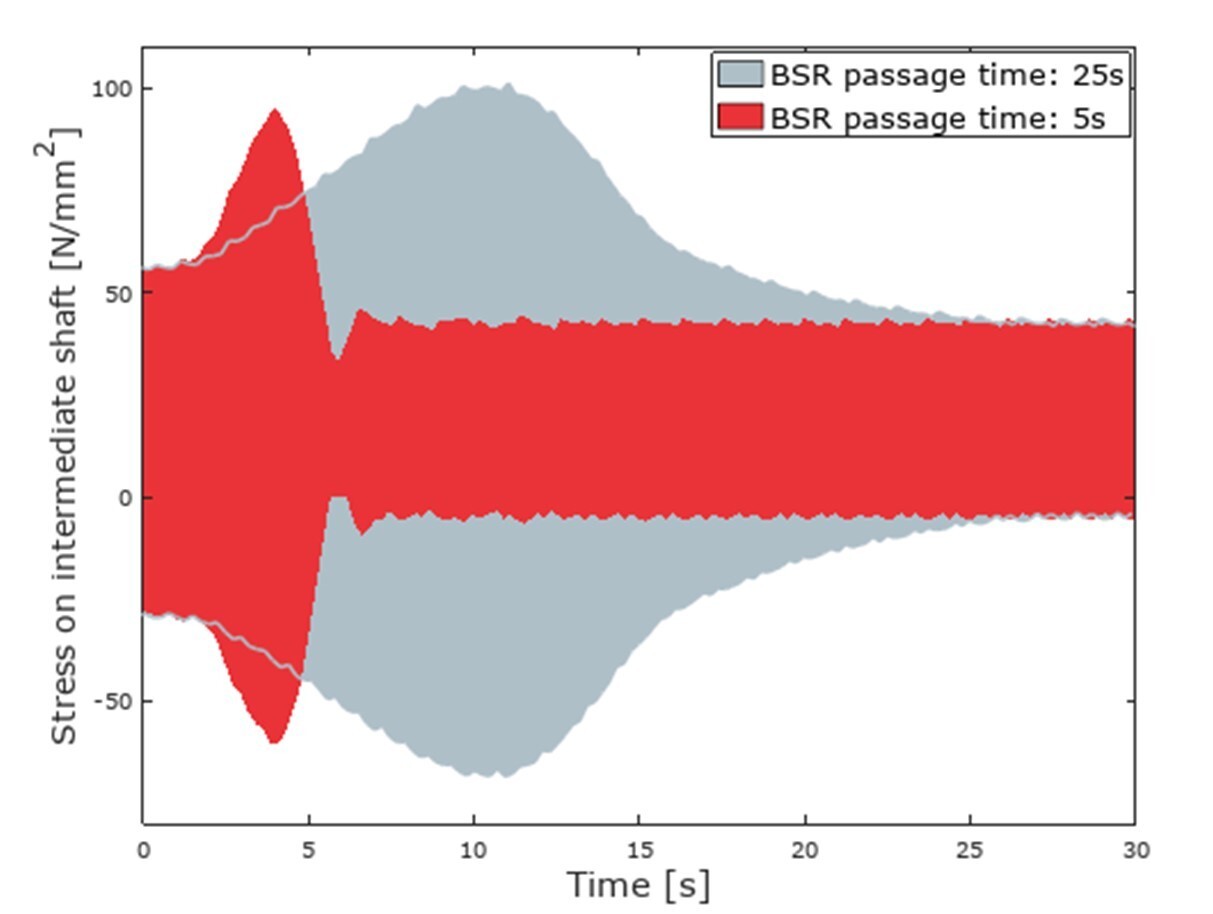

Dr. Klaus Prenninger, Manager for Torsional Vibration Calculation at Geislinger GmbH, presented the paper “Capabilities of Transient Simulations in the Torsional Vibration Damper Selection” (co-authors, Matthias Geislinger and Dr. Andreas Thalhammer). Usually, for vessels equipped with two-stroke engines, a strong first order resonance below 60% of the nominal speed is present. For such propulsion systems, a barred speed range (BSR) is often introduced that must be passed in a rather short time to avoid damage to the powertrain. Simulations can provide valuable information about the torsional response when passing such a barred speed range. The following illustration shows an example of such a calculation for different passing times through the critical speed range, where resonance-effects occur in the system.

The calculated response data is essential for a detailed fatigue analysis of the shaft line as this has a substantial influence on the lifetime of the considered propulsion system.

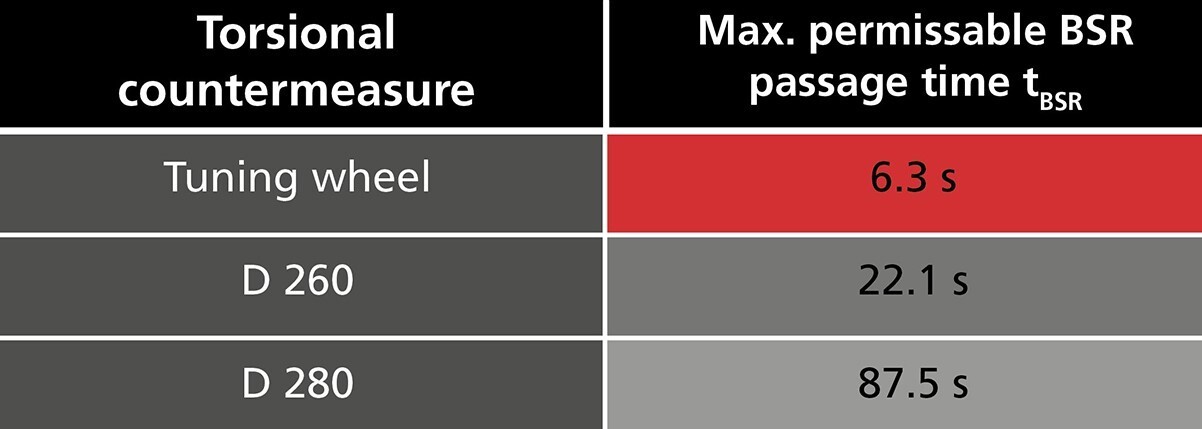

For the different systems, the new DNVGL rule restricts the max. permissible time for a BSR passage according to the calculated values. Using a specifically adapted Geislinger spring damper, the time in the BSR can be extended significantly without breaking the DNVGL restrictions. Thus, more economical engines with less power, which need a longer time to pass the BSR, can be used. The Geislinger Damper protects the powertrain reliably and enables economic engine solutions.

Our paper was of high interest for many attendees as there are numerous problems, where a detailed understanding of the torsional response of the powertrain to a non-steady state behavior is important.

Additionally, Geislinger attended with an exhibition booth and presented the newest product innovations. Our customers could gain new ideas and insights, discussing innovative, future concepts on combustion technology with the Geislinger team. Surrounded by the impressive scenery of Vancouver, Geislinger could offer innovative and environmentally sustainable solutions for combustion engines.

The full paper is available for download here. All copyrights of the paper belong to CIMAC (International Council on Combustion Engines).