SHARE ON:

Link copied!

CRP is the abbreviation for Counter Rotating Propeller. The two propellers of the two-stroke engine rotate in the opposite direction and thus save up to 15 % of fuel. Taking into account a consumption of 80 tonnes of heavy fuel each day this saves money and reduces the emission of CO ² significantly.

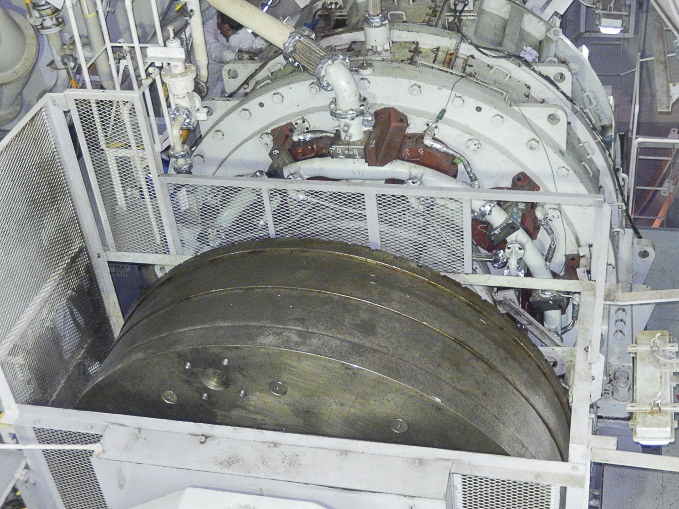

The after propeller is directly connected to the engine and turns in the engine’s direction of rotation. Approx. half of the engine power is transmitted by the outer part of the coupling to the planetary gear and drives the forward propeller in the reverse direction.

The service of the BE 280 was carried out directly on board the VLCC mega-tanker, which is a logistical as well as a technical challenge. After a few months of preparation a Geislinger service engineer conducted the service of the largest Geislinger coupling successfully: After 70.000 operating hours our CRP-coupling is in the best condition and therefore meets its demands for longevity and low maintenance costs.