SHARE ON:

Link copied!

Geislinger teamed up with the Centre for Wind Power Drives (CWD), a department of the RWTH Aachen University, to run pre-post simulations with one of their generic multi-body simulation models. A state-of-the-art 6MW offshore turbine, allowing simulations in 6DOF (degrees of freedom), with four-point suspension (locating and floating bearing), and a three-stepped gearbox with elastic mounts and hydraulic torque support was used as a reference model. Taking into consideration its stiffness and damping values, a Compowind® CW 240 was designed and integrated into the coupling model, while the gearbox was modelled rigidly to the main frame.

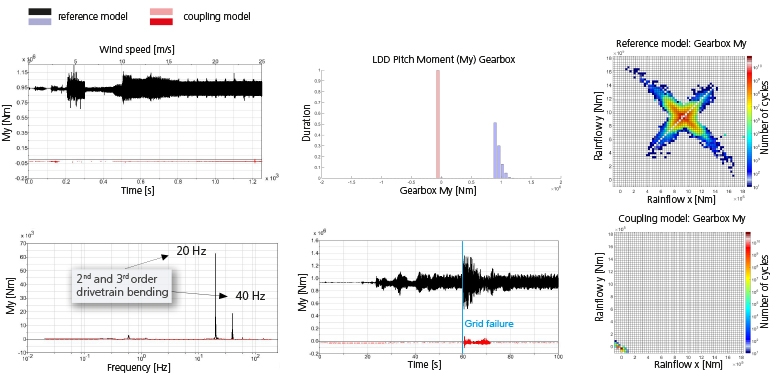

Dynamic simulation, bearing in mind the design load, turbulence and special events, together with statistical examinations (LDD, Rainflow-counting) delivered plenty of valuable results. Comparisons to the reference model allow exact determination of the coupling’s contribution to reduce load and fatigue. Pictured below a comparison of the pitch moment (My) on the gearbox input shaft:

- The load analysis at steady-state operation (top left) distinctly illustrates the reduction of moments transmitted over the y-axis in the coupling model. This is a result of the gearbox mounted rigidly to the main frame. In addition, significantly higher dynamic load caused by excitations of drivetrain bending Eigen modes can be noticed in the reference model (bottom left).

- The LDD analysis (top center) shows a wide load spectrum of the reference model (excitations of drivetrain bending Eigen modes); whereas there is only one load bin in the coupling model (the moment oscillates around a central position with very low amplitudes).

- Rainflow-counting (images right side) mirrors the LDD results. The central position in the coupling model around zero and the low oscillating amplitudes reflect the vast reduction of moment over the y-axis transmitted to the gearbox.

- Even in the event of a grid failure (bottom center), the coupling model ensures - thanks to its damping characteristic - clearly reduced dynamics.

The pre-post study clearly demonstrates that non-torque loads are reduced significantly by decoupling the drivetrain from the rotor with the Compowind® coupling. Even under normal operating conditions, the load on the input shaft of the gearbox reduces by an order of magnitude and even more. Excitation of drivetrain Eigen modes and the transmission of system Eigen frequencies into the gearbox are virtually eliminated and improve the dynamic behavior. The load consideration after the occurrence of special events like extreme gusts or grid failures show that the Compowind® ensures incomparable lower post-pulse oscillation. The results conclusively show that the Compowind® coupling on the low-speed side of a wind turbine makes a significant reduction to loads on the gearbox. The dynamic behavior of the whole system improves noticeably, and so does the reliability of the drivetrain.