SHARE ON:

Link copied!

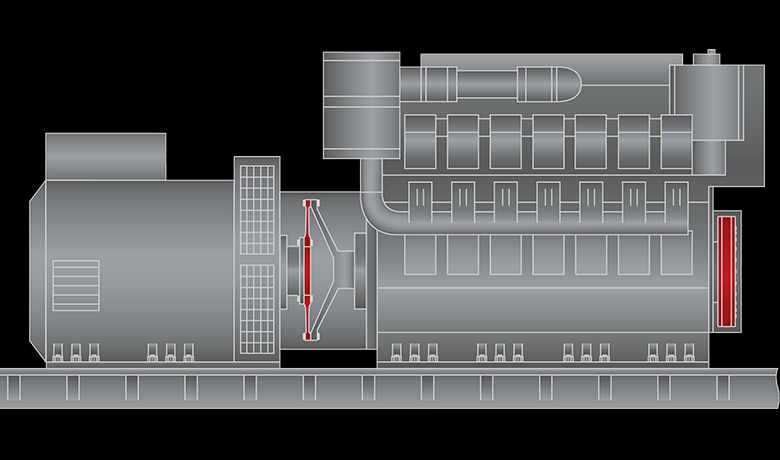

The Belaz 75710 for example, launched by the Belarusian Company Belaz, is currently the biggest mining dump truck in the world. The truck, with a payload capacity of 496 tonnes, is 20.6m long, 8.16 m high and 9.87m wide. The Belaz dump truck is the first vehicle of its kind where two engines are producing the power to drive the wheels. It features two 16-cylinder turbocharged diesel engines of the MTU series 4000 with a power output of 2,300HP of each engine. If the truck is fully loaded, both engines operate; if the haul truck is empty, one engine is idling. In order to be able to transport the heavy mass, the giant Belaz is equipped with eight tyres, instead of the usual four or six.

Geislinger realized at an early stage that the Geislinger Gesilco® Disc is the ideal solution for mining application and the perfect substitution of steel components. The Gesilco® Disc with a double membrane was presented for the very first time in the year 2000. In the beginning a lot of work was necessary to convince dump truck and engine manufactures of this fibre composite product. In the meantime, all big dump truck manufacturers worldwide rely on the Geislinger Disc: they realized that the carbon fibre composite coupling with its non-magnetic and non-conductive properties has the same core benefits as the steel coupling. Furthermore, the Gesilco® Coupling offers additional benefits:

The Geislinger Gesilco® Disc is a coupling for diesel electric drives for outputs up to 3000kW. The flat membrane made of fibre composite materials allows very high torques to be transmitted at high engine speeds. The Gesilco® Disc is a maintenance-free misalignment coupling. The light-weight, highly-flexible carbon fibre composite coupling is ideally suited for mining applications. With its non-magnetic and non-conductive properties the Geislinger Disc operates in operational temperatures ranging from -20°C up to +100°C. The Geislinger Disc connects the generator with the combustion engine, isolates the generator from the engine and protects from potential crankshaft bearing failures through electric corrosion. Furthermore, the isolating Gesilco® Disc absorbs high radial forces while transmitting high vibratory torques with the lowest reaction forces.

Geislinger is proud to equip those huge giants which are operating in the remotest and roughest parts of the world under extreme conditions with its Gesilco® Disc coupling beside the D44 damper which protects the crankshaft.