SHARE ON:

Link copied!

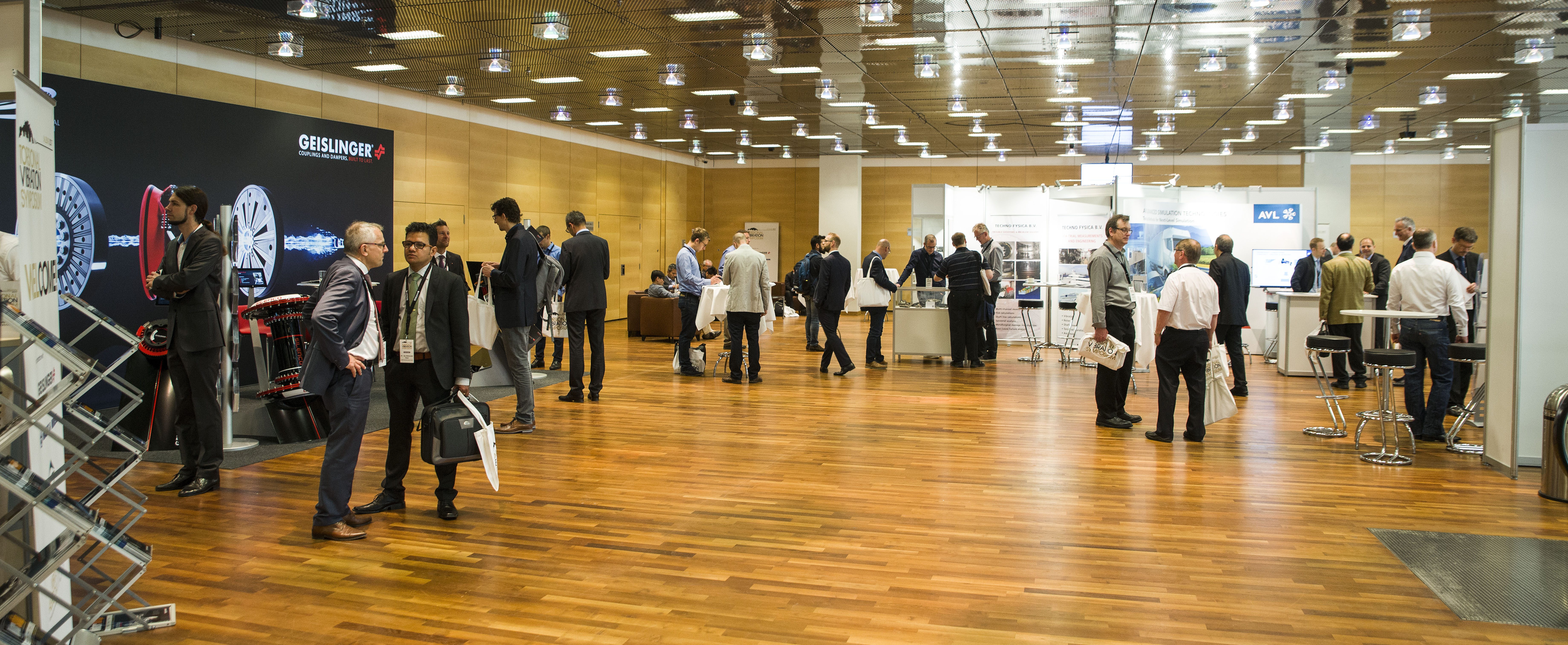

For the second time the city of Salzburg hosted the one-of-a-kind Torsional Vibration Symposium and it brought together more than 220 participants from all over the world to exchange their knowledge and get an insight into the newest scientific findings in the field of torsional vibration.

From May 17th – 19th 2017 experts involved in the power transmission sector could take part in more than 40 lectures presenting the newest technical trends and findings. Supervised by an advisory board of international specialists a diverse spectrum of subject areas, from system design & development to future concepts was addressed and discussed.

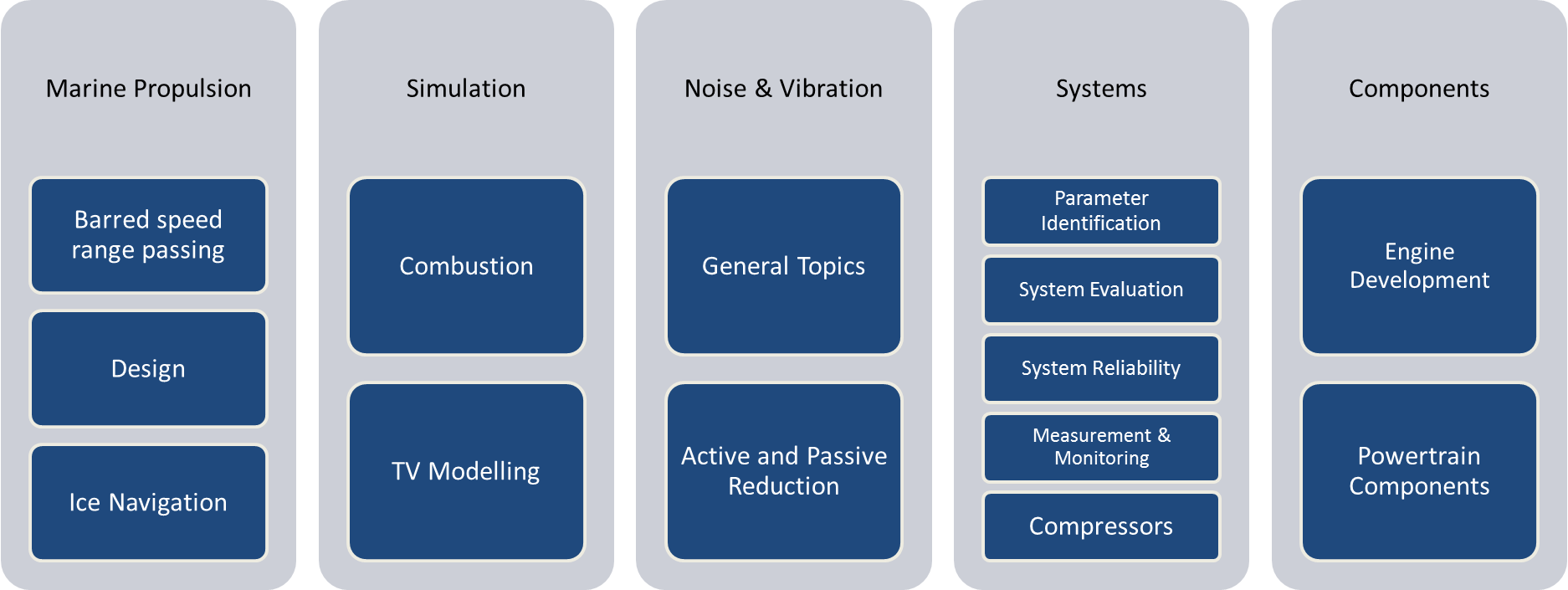

More than 40 presentations were held during the second TVS covering the following fields:

Geislinger participated with 3 presentations:

“Influence of Damping Factors on Coupling Applications” (session: Powertrain components – elastic coupling)

“Effects on Engine and Vessel Operating Conditions on Torsional Vibration Dampers” (session: “Engine Development – future concepts”).

Furthermore, together with Renk AG, Geislinger handed in a paper regarding “Vibration isolation of heavy machinery.”

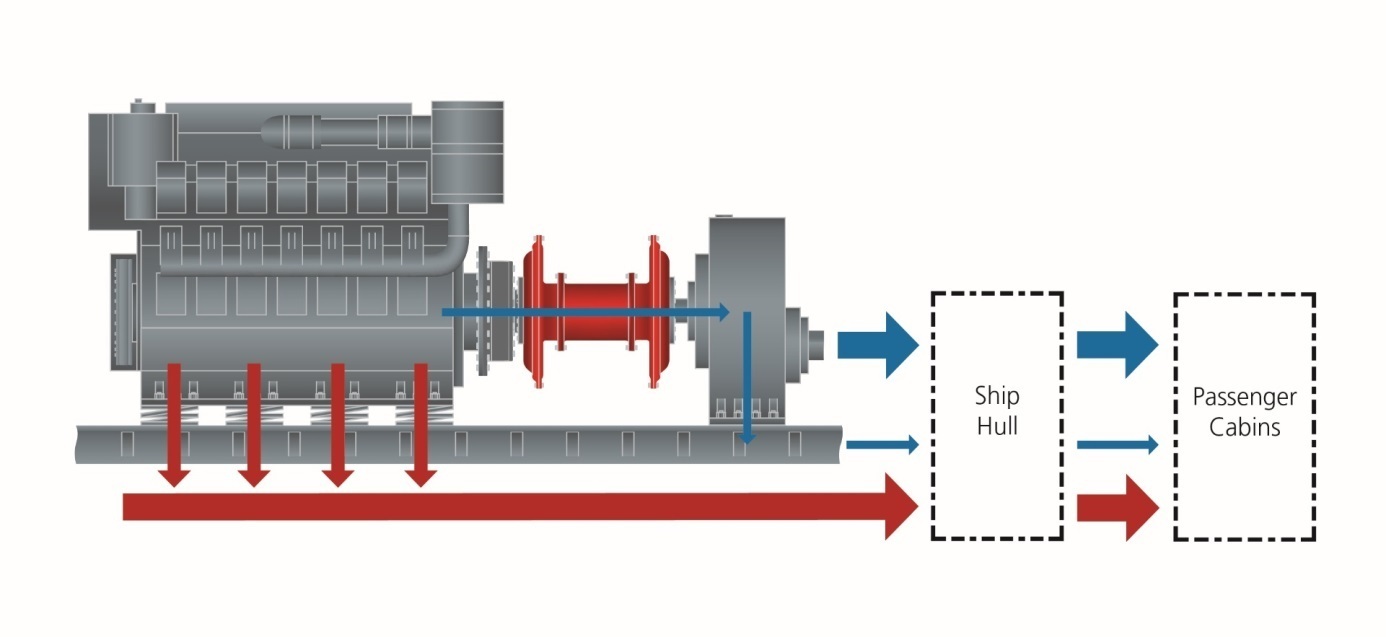

It included the principles of noise reduction for marine propulsion systems and the transfer path of structure borne noise. The full potential of a resilient mounting system is achieved only if all other transmission paths are considered. The primary transfer path goes via the engine mounts and the gearbox into the ship’s structure, as shown by the red lines in the figure below. The secondary path goes along the powertrain via coupling, gearbox, gearbox mounts, shaft and its bearing into the ship’s hull, as shown by the blue lines.

Solutions to minimise the sound-transfer along the primary path are, for example, soft, optimised mountings as described above or active systems. For the secondary path, which has come to be of interest in recent years, an elastic coupling that can absorb vibrations and compensate for misalignment is the best solution for noise reduction. One example is the Geislinger Silenco®.

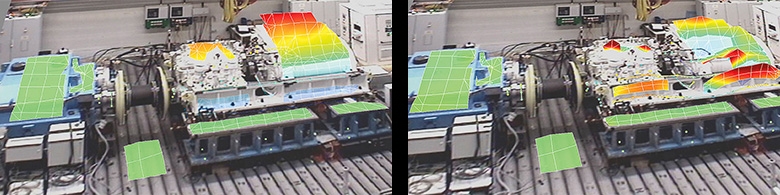

One example, where the Silenco-coupling is used, is the Renk Advanced Electric Drive (AED). For this application, the transfer paths of the structure borne noise have been analysed and measured in detail at the Renk test bed. In the following image, two of the major operational modes are shown. The intensity of the red and blue colours indicates the surface velocity towards or away from the position of a laser vibrometer. The light green colour indicates no major values.

But there is a dynamic interaction between the shipside machinery foundation, the resilient mounting system and the stiffness and vibration characteristics of the machinery itself. Thus, the results measured at a test facility can always be different from the results of the real system. This makes an on board validation essential.

Due to the great success of the event, the organizer already announced, that the 3rd Torsional Vibration Symposium is scheduled for May 13th - May 15th 2020 in Salzburg, Austria.