SHARE ON:

Link copied!

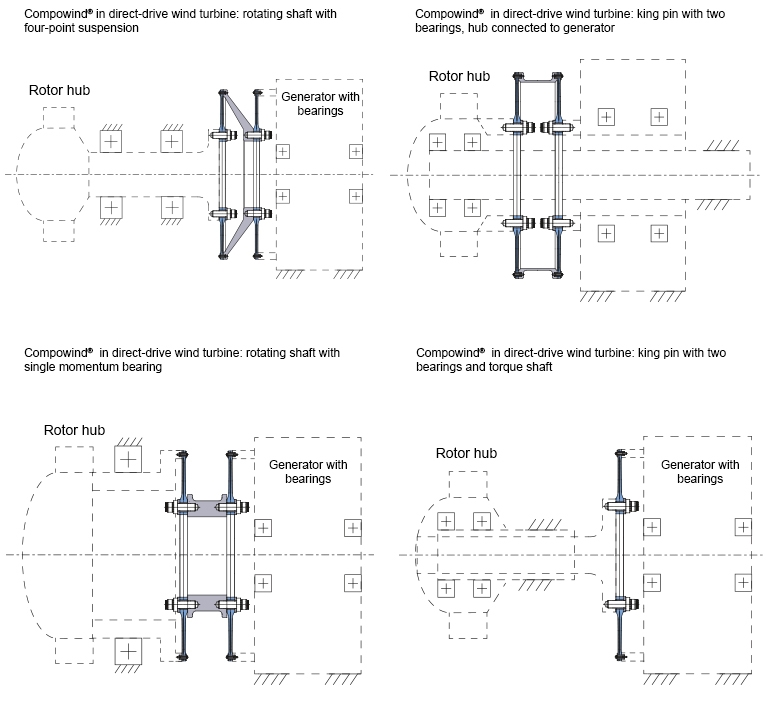

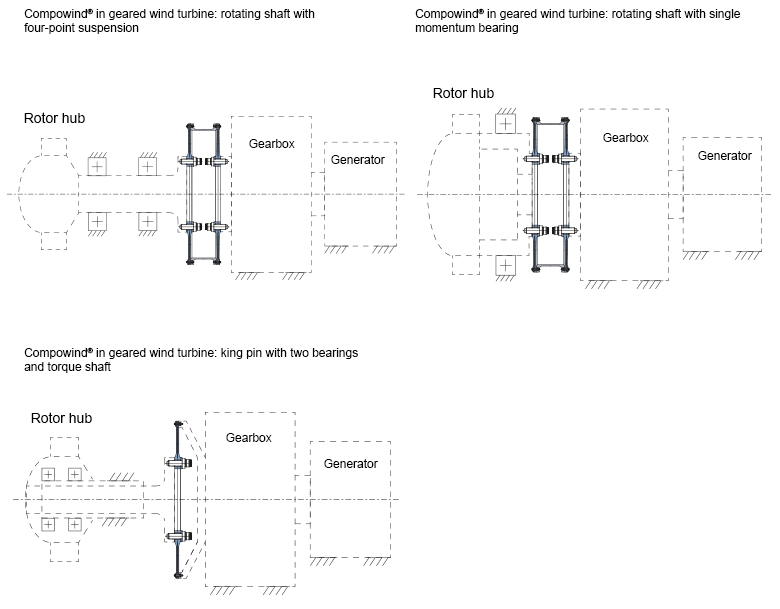

The Pre-Post Study of the Geislinger Compowind® Coupling is based on a wind turbine with a four-point suspension and a gearbox with hydraulic torque support. Further basic configurations of various geared and direct-drive bearings for wind turbine drive-train concepts can be seen below:

The Geislinger Compowind® is a lightweight, fatigue-resistant, and maintenance-free composite low-speed coupling which absorbs misalignments and bending moments efficiently. Therefore, the advanced carbon fibre reinforced composite membrane coupling protects the gearbox and the whole drivetrain from non-torque loads. The illustrations depicted above exemplary indicate possible pure torque drive-train solutions.

To meet the demands of different applications, each Compowind® coupling is customized and thus perfectly integrated into the individual drivetrain layout. Furthermore, different Compowind® designs ensure fitting interfaces to the adjacent components.