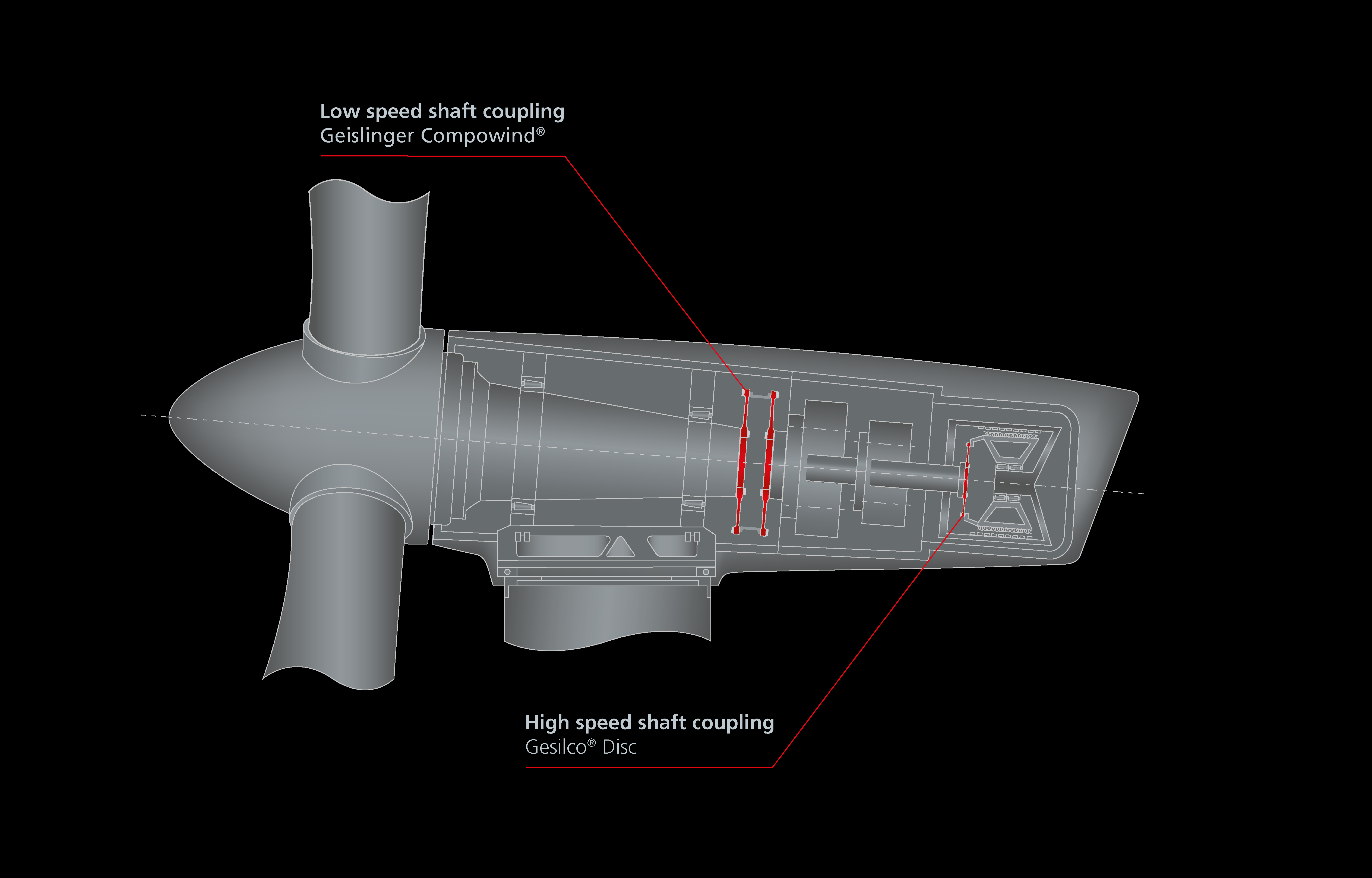

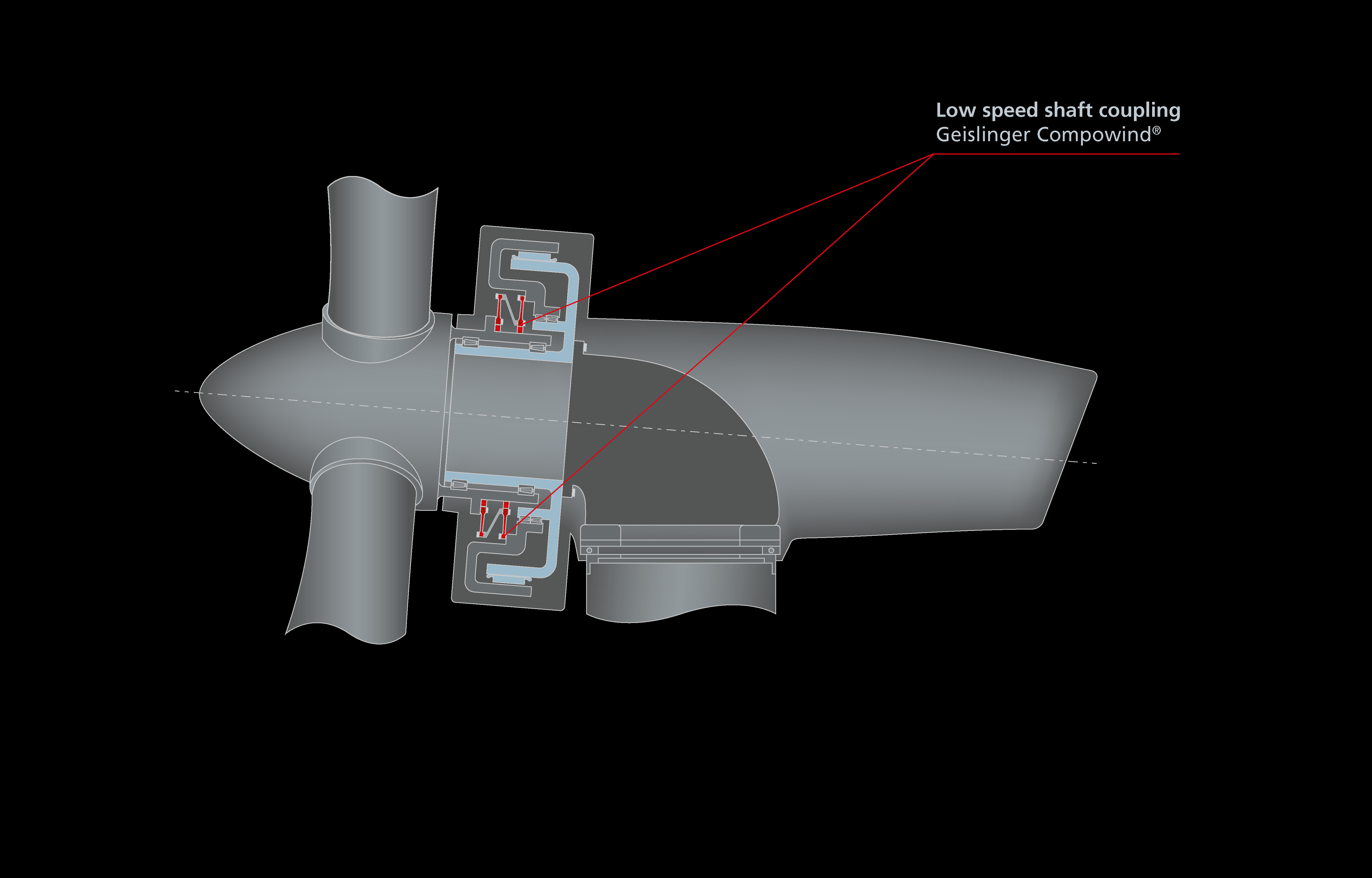

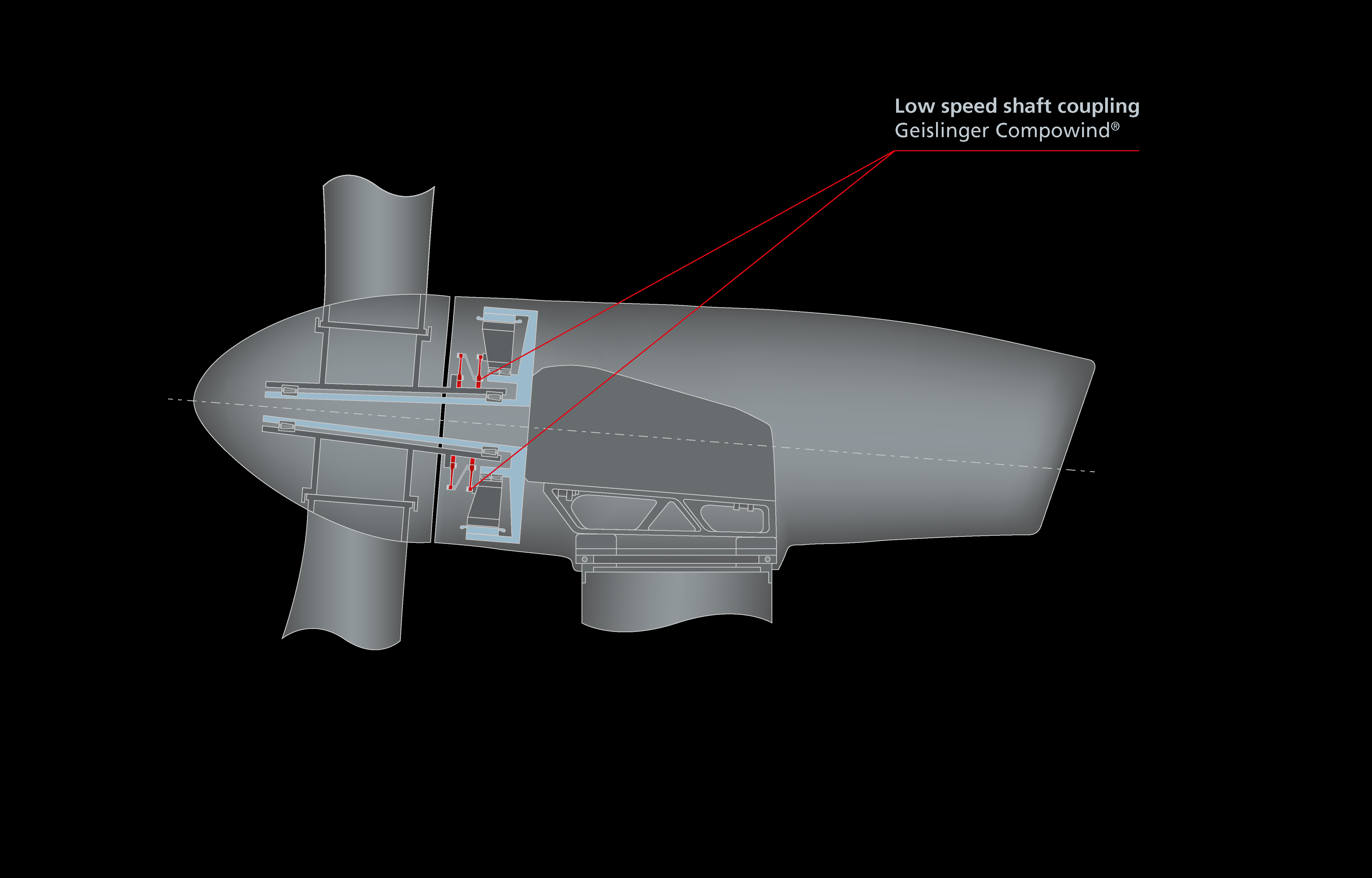

COMPOWIND® allows the gearbox to be rigidly attached to the main frame, thus drivetrain bending Eigenmodes are virtually eliminated, and dynamic behavior is improved beyond comparison. This is not only important under severe load conditions and after the occurrence of special events, but also helps to reduce structure-borne mechanical wind turbine noise: The comparatively low stiffness and the good damping properties of the Geislinger COMPOWIND® reduce the sound transfer from the gearbox through the rotor shaft to the rotor blades, while the attenuation of Eigenmodes helps to reduce sound propagation within the drivetrain in general. For this reason, the noise radiation from the rotor blades, the gearbox housing, the gearbox supports, and the tower is effectively reduced. This poses an additional customer value and a clear competitive advantage for onshore applications.