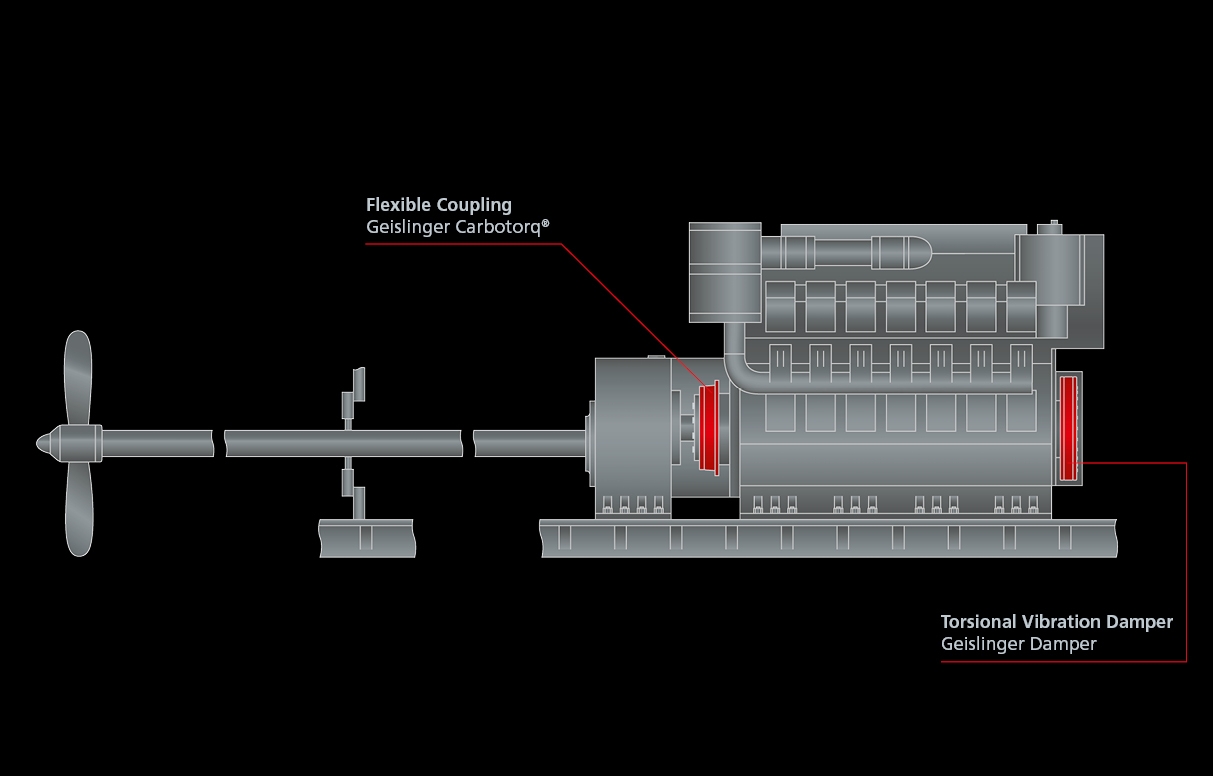

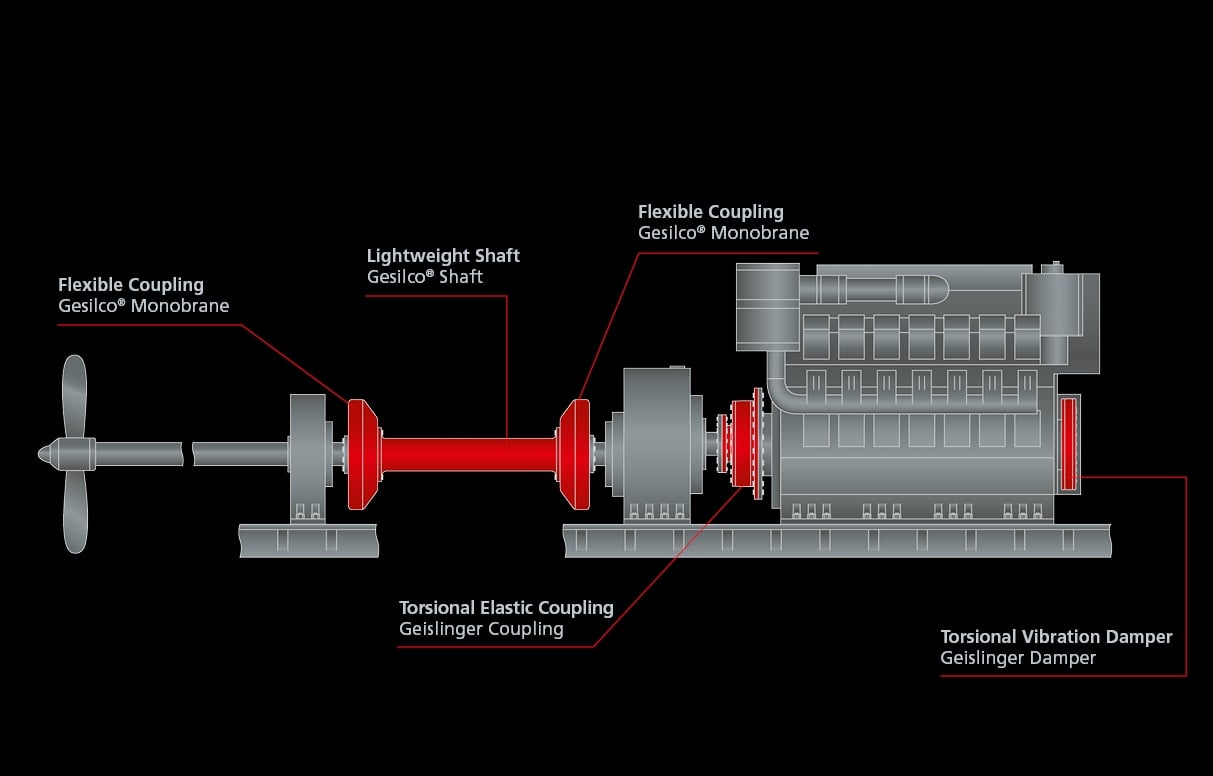

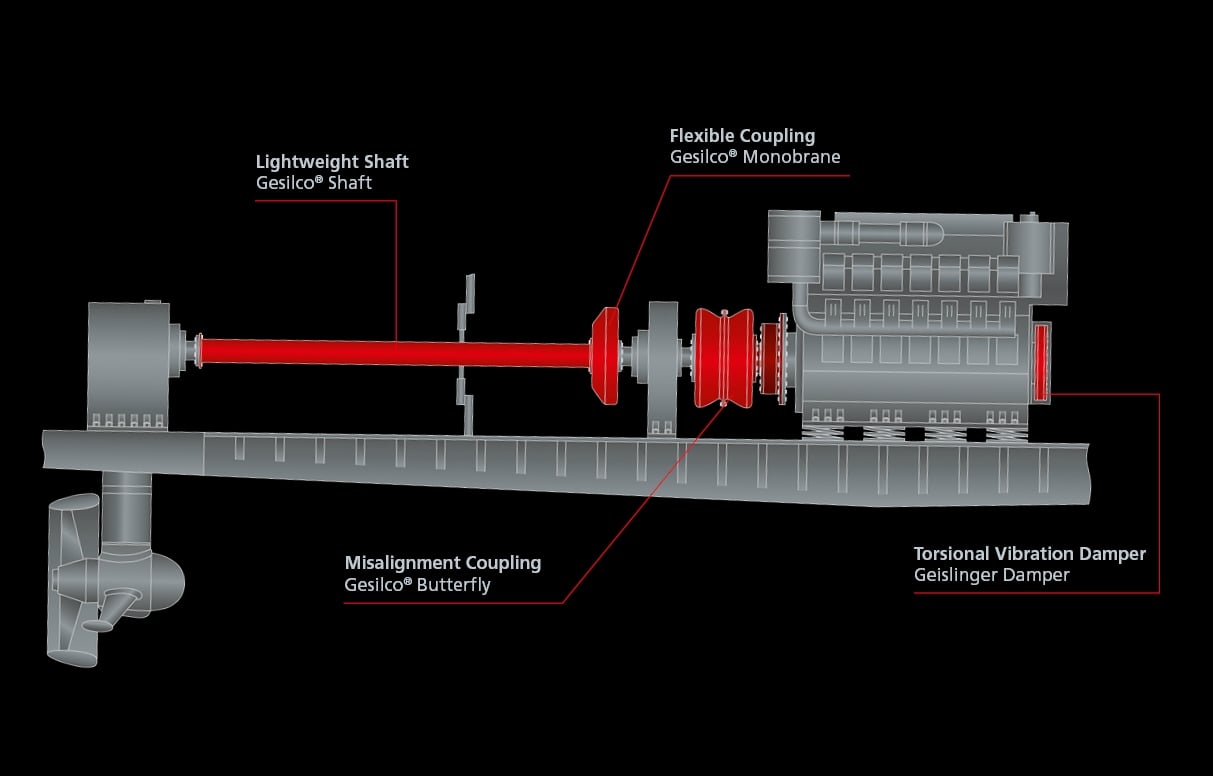

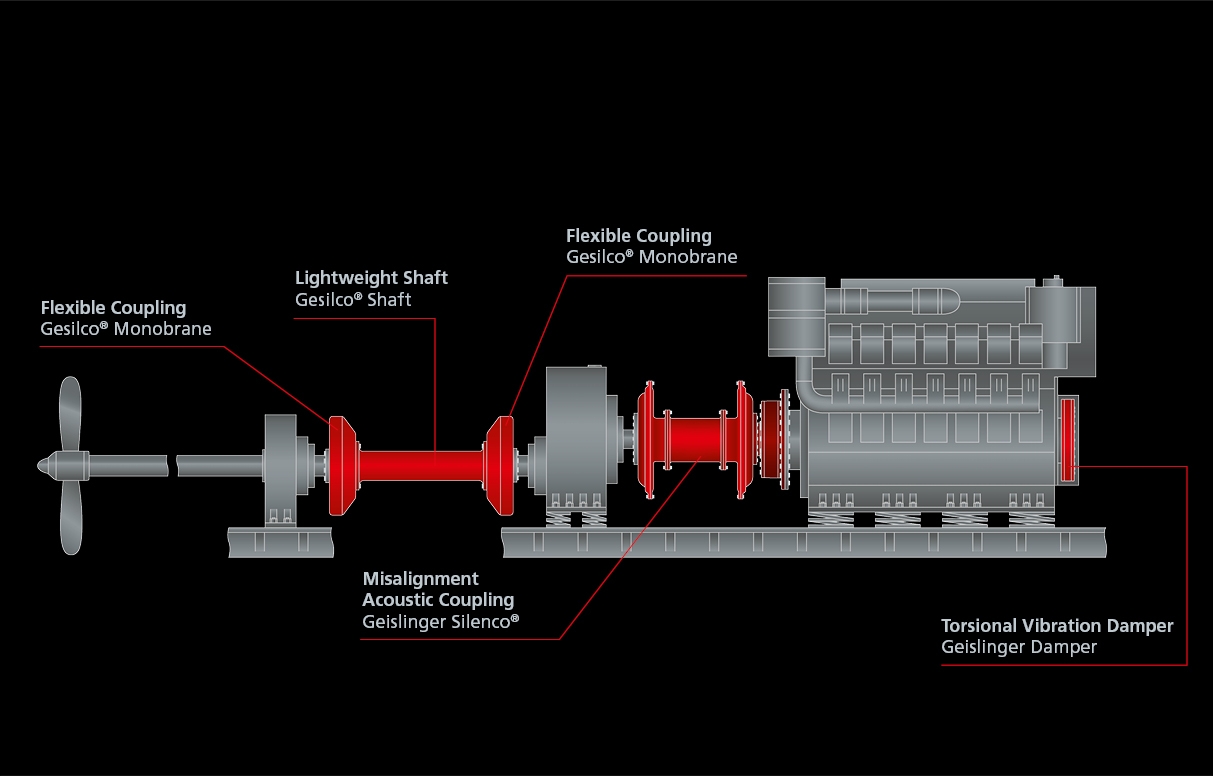

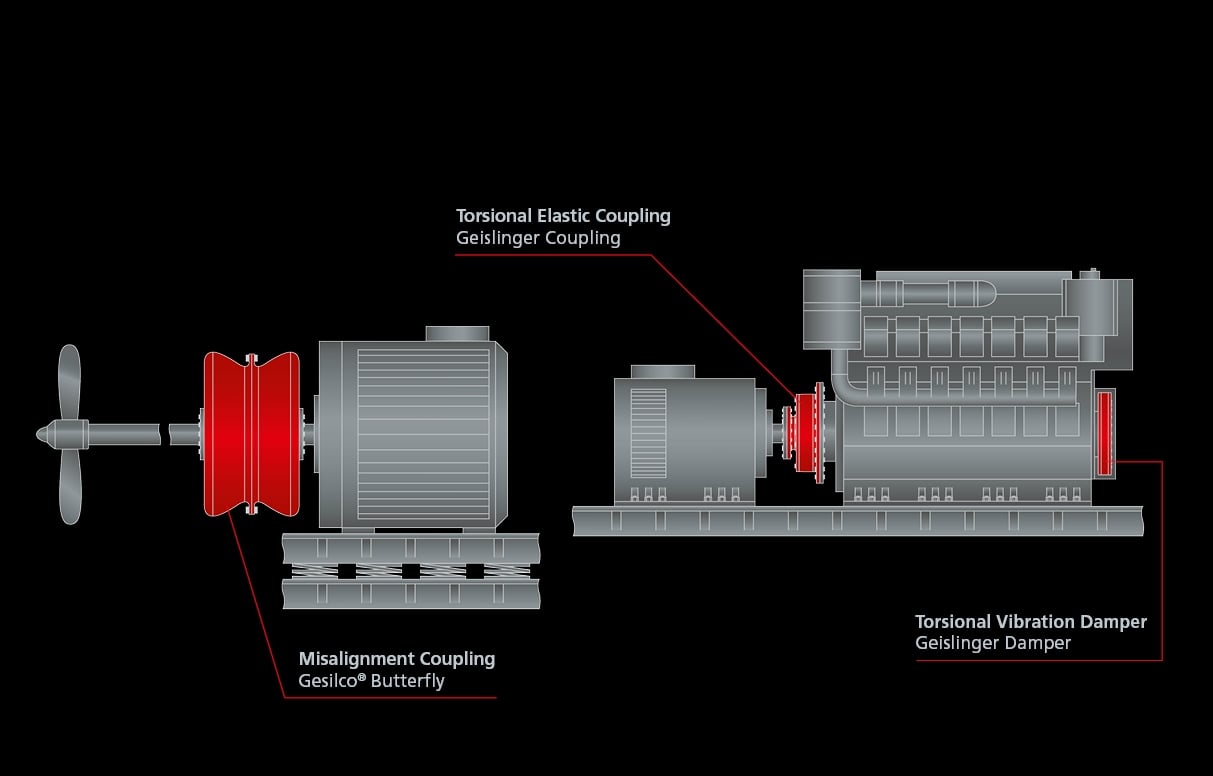

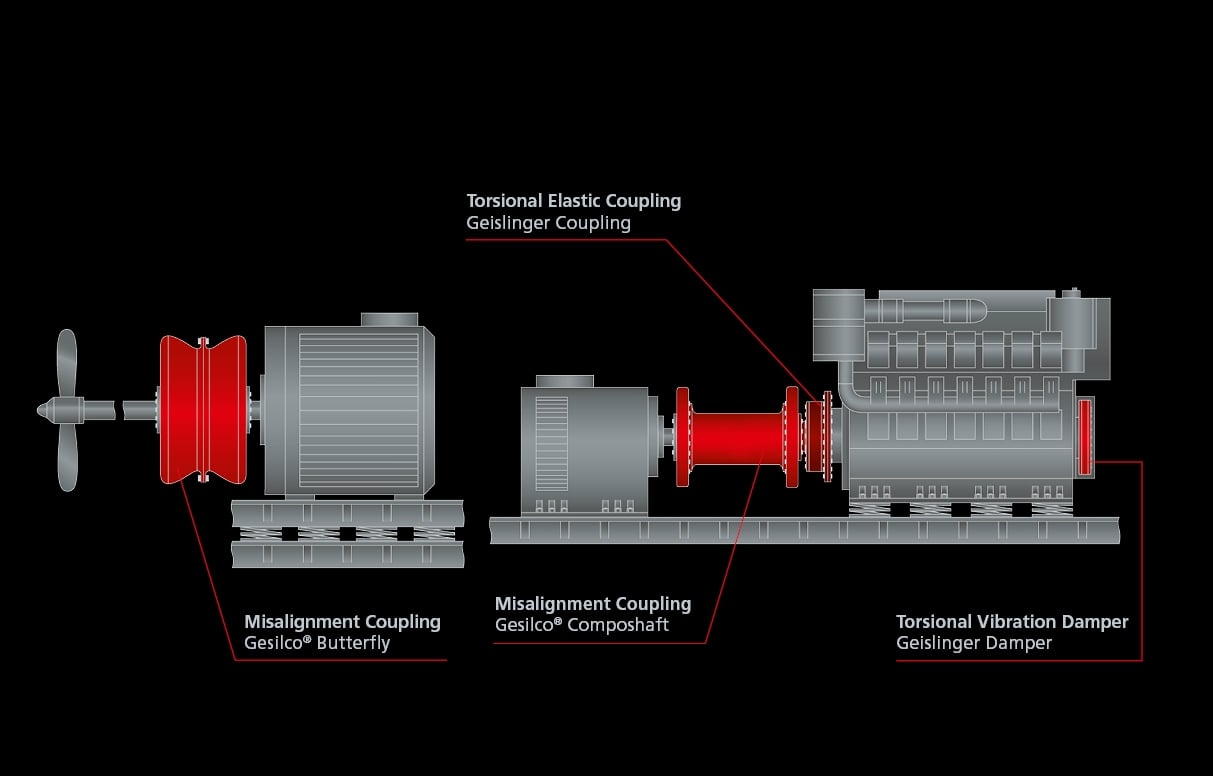

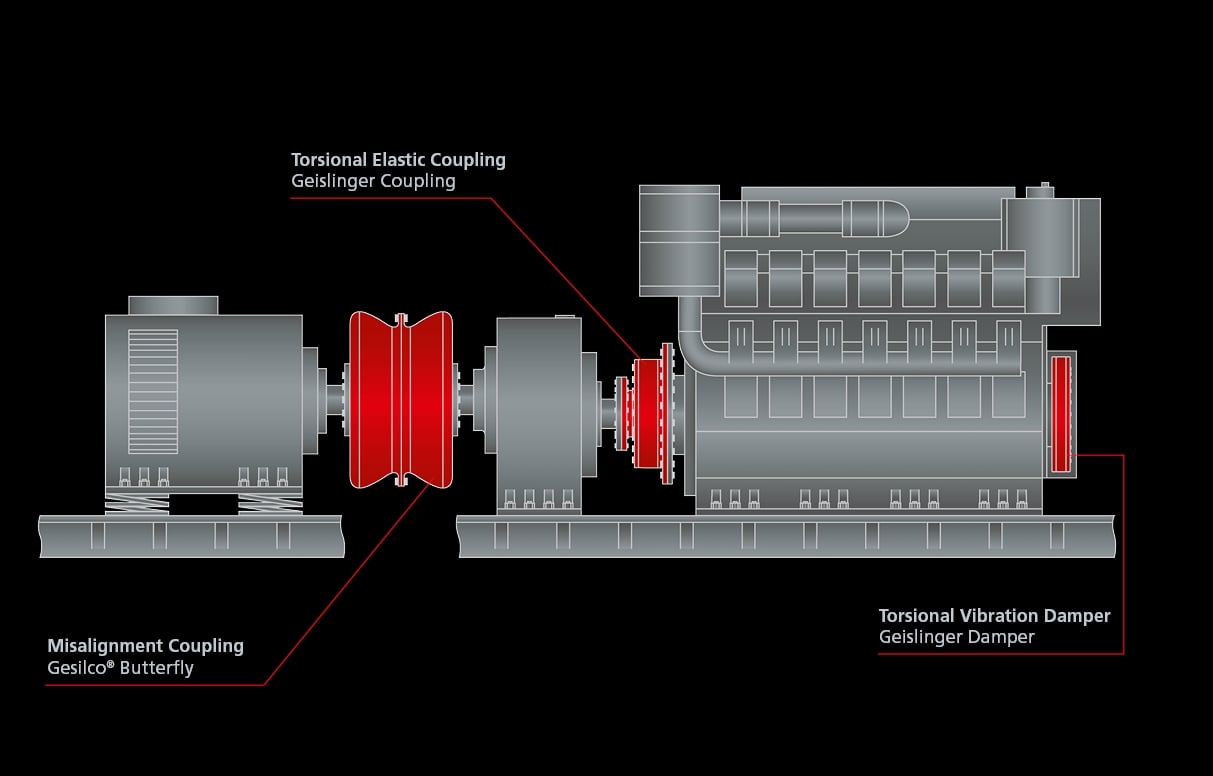

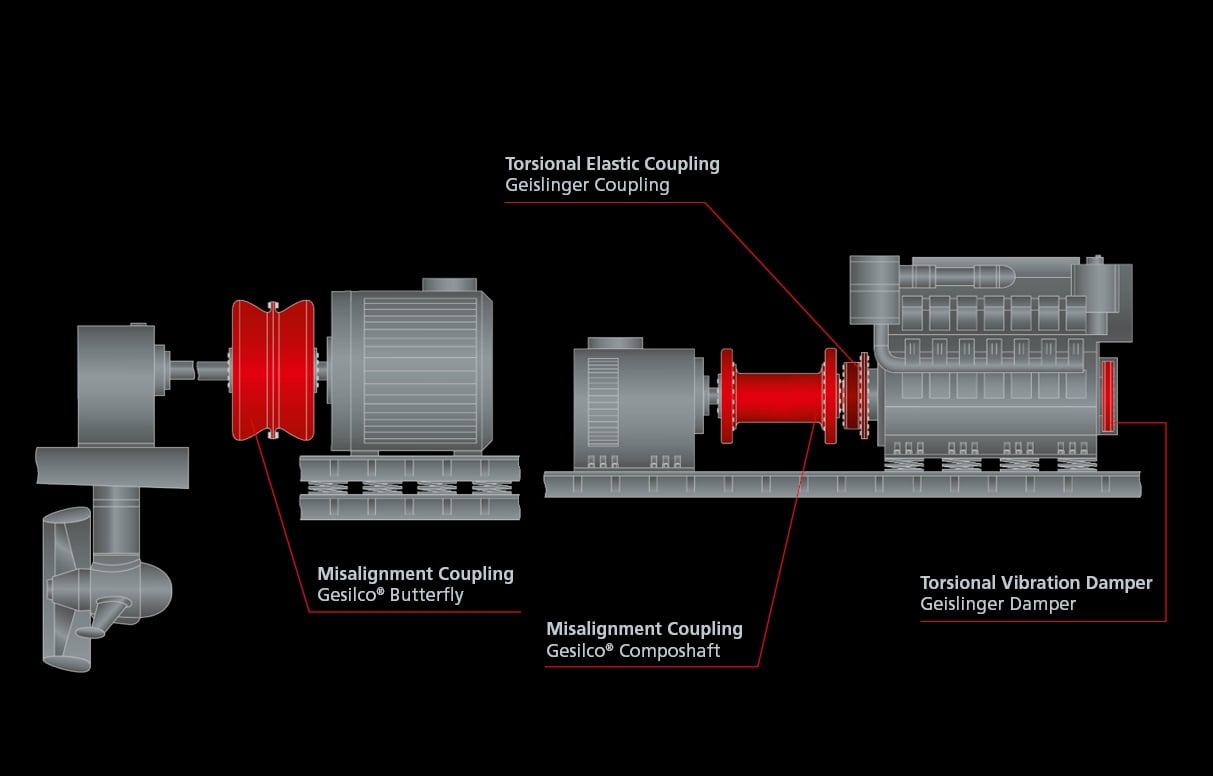

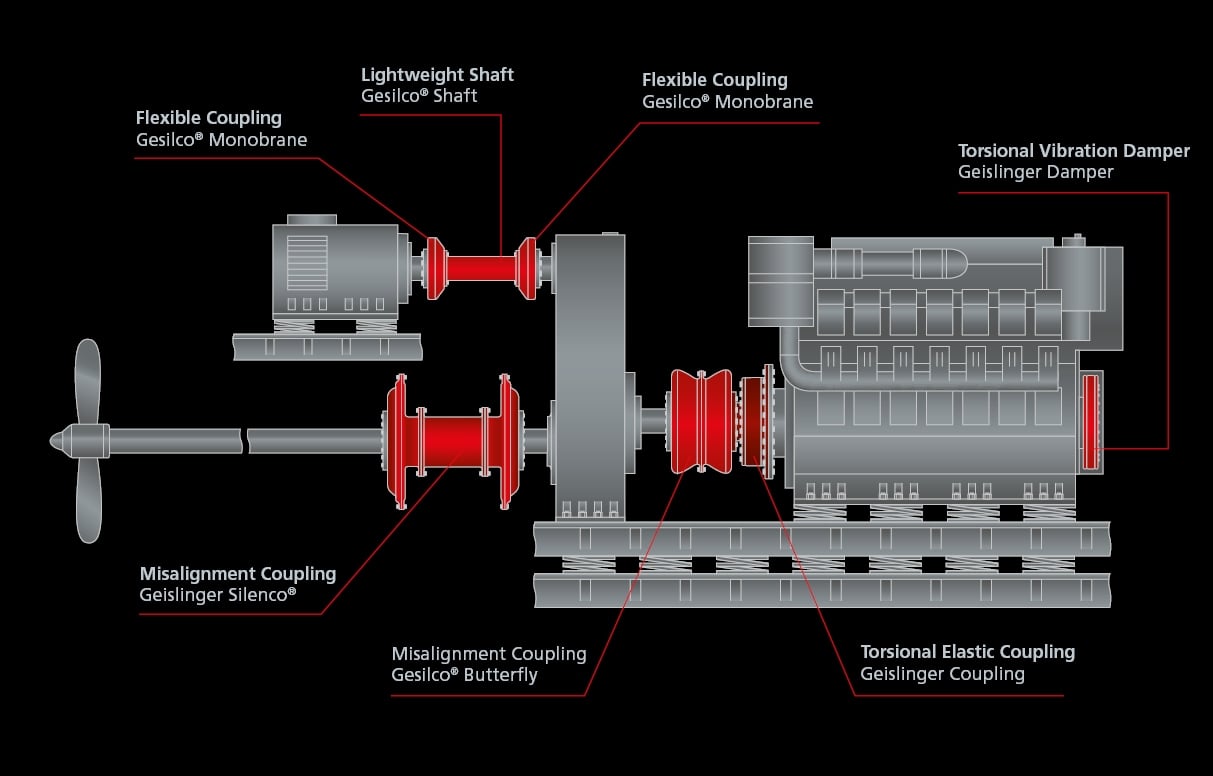

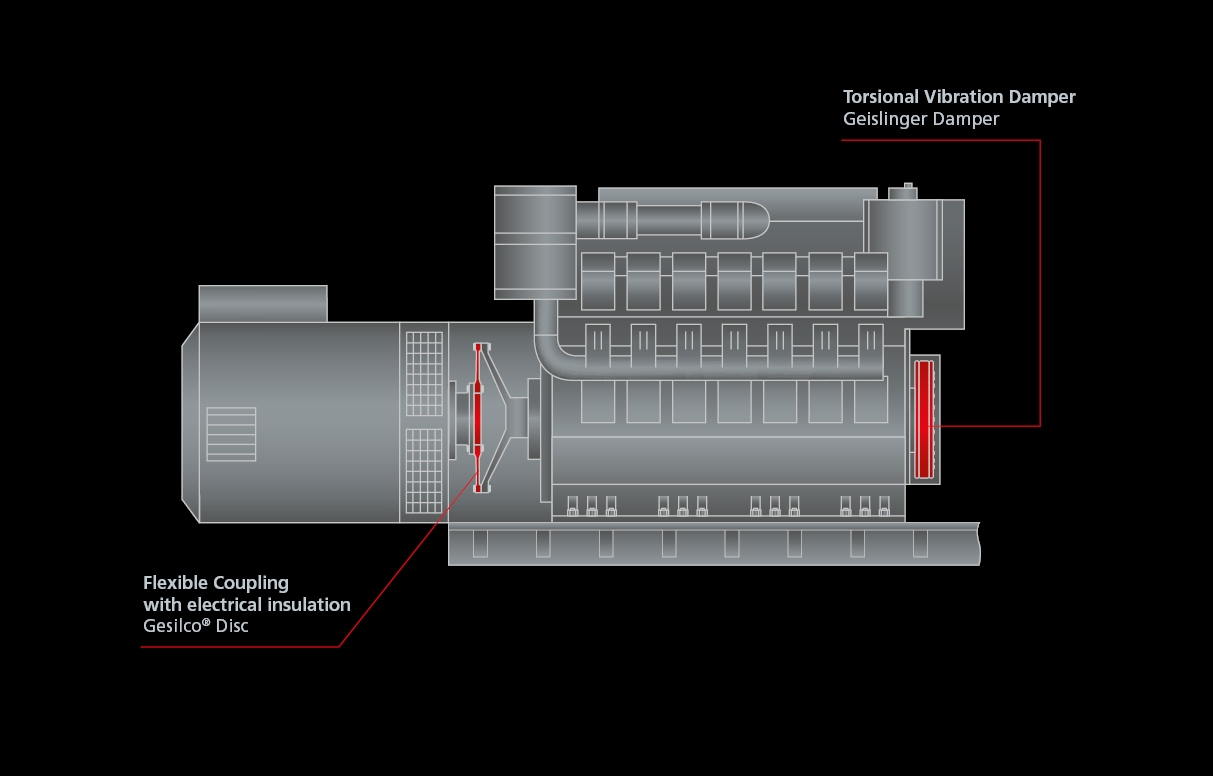

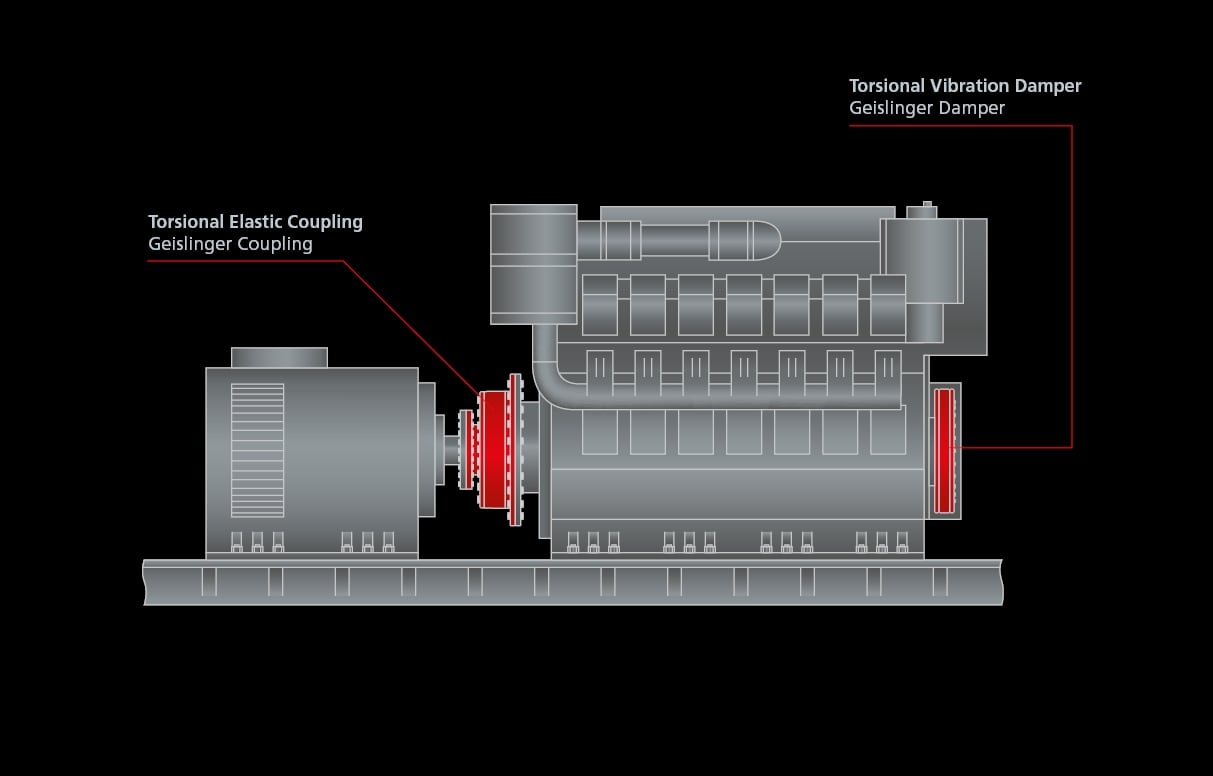

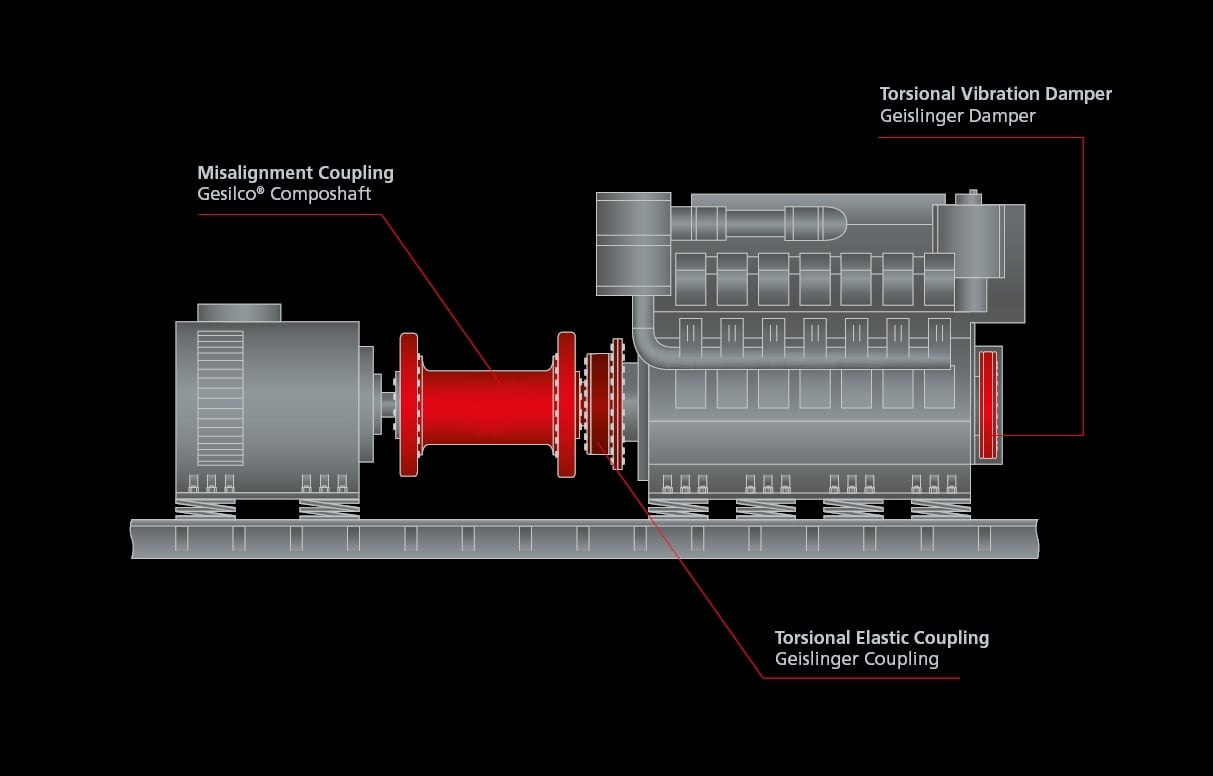

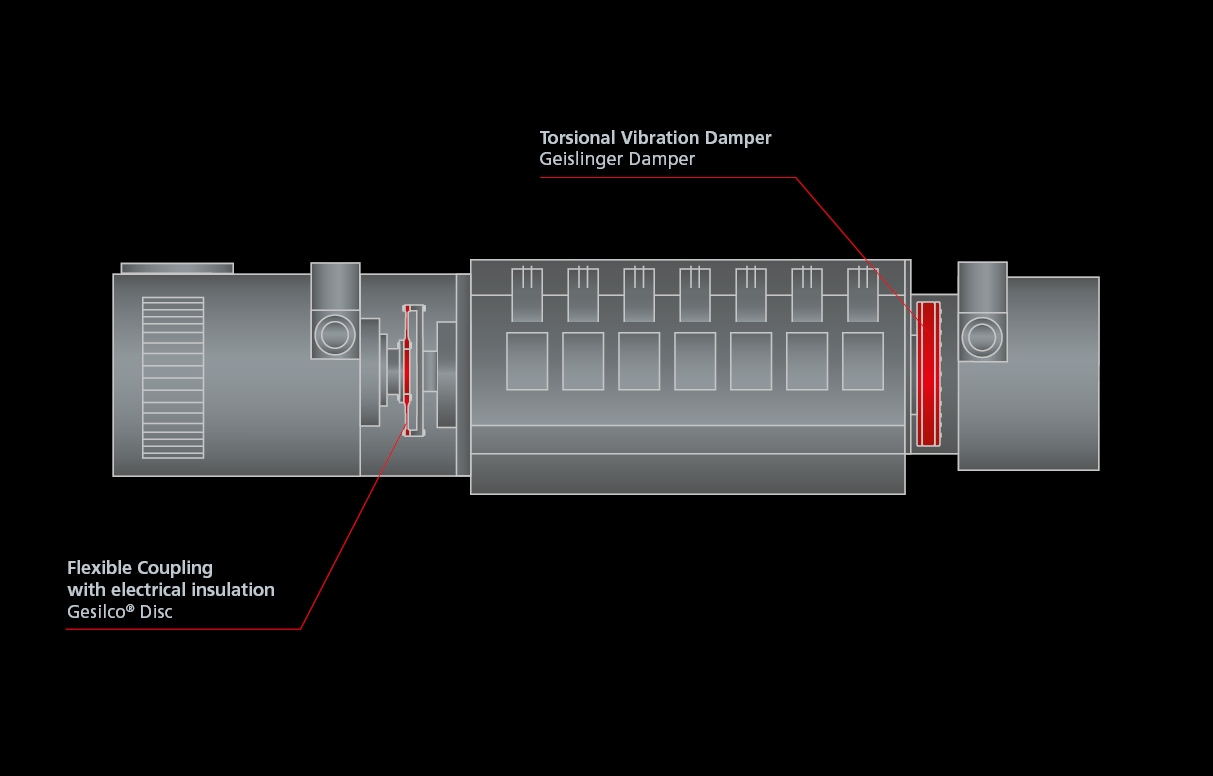

Customized solutions

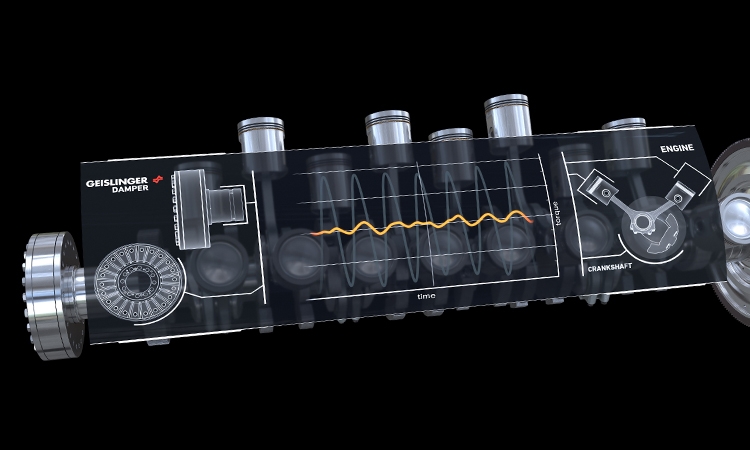

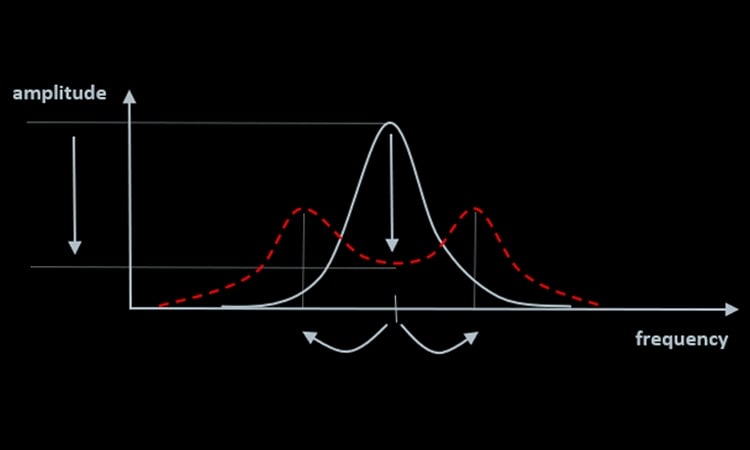

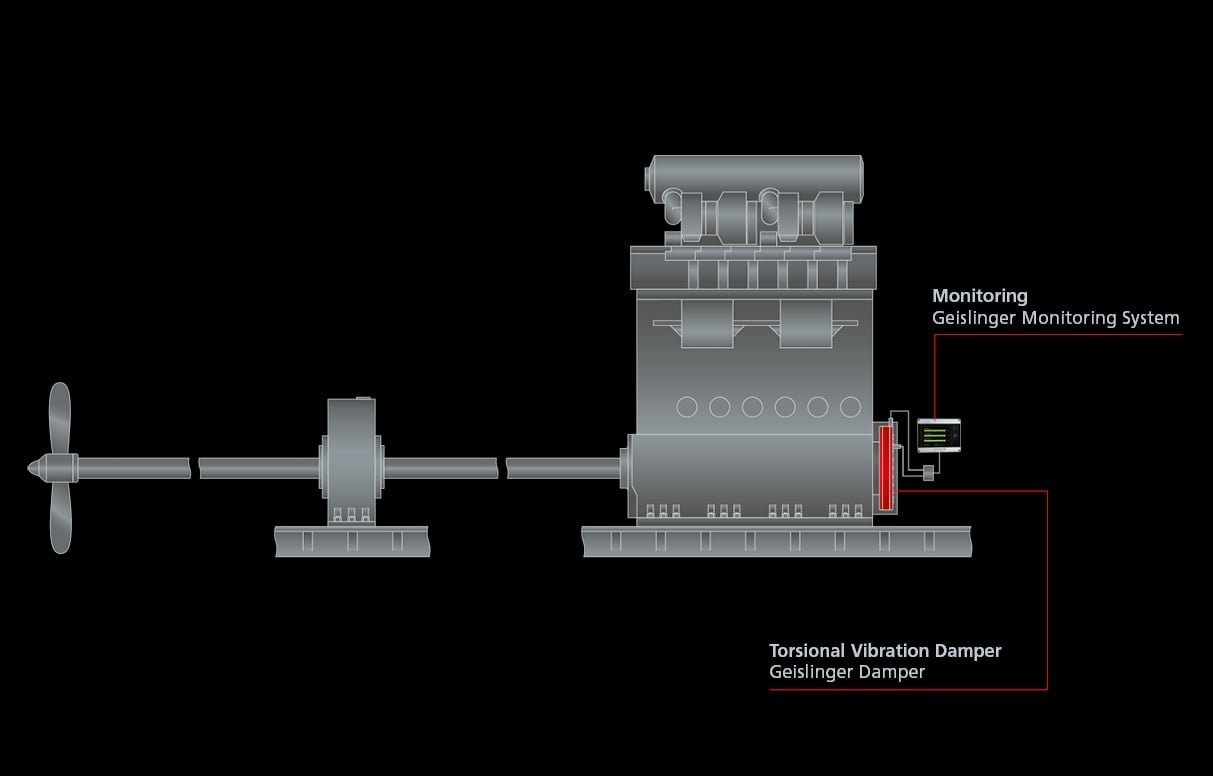

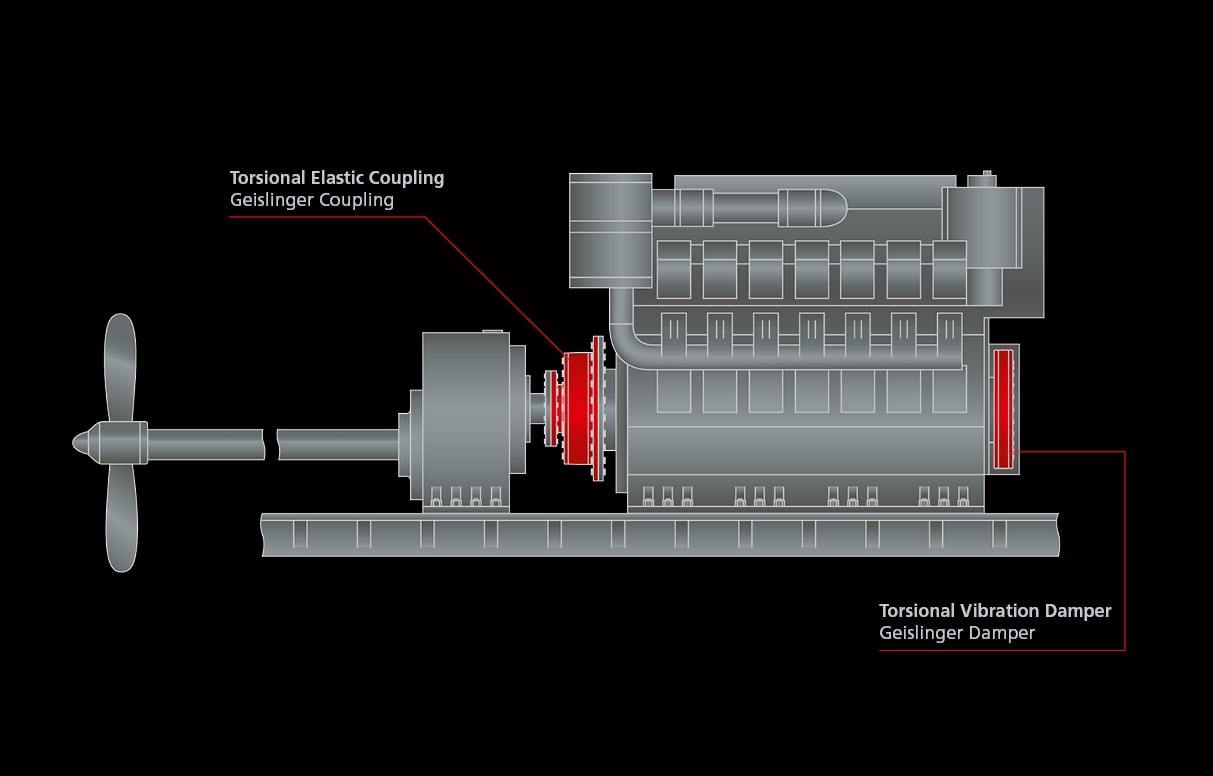

The Geislinger Damper is specifically designed for high demanding applications, like larger gas and diesel engines as well as reciprocating compressors. Geislinger offers tailor-made solutions for your torsional vibration challenge along with torsional vibration calculation, manufacturing, commissioning, and measurement analysis. Using state-of-the-art manufacturing facilities, we tailor each product precisely for any individual system, providing the perfect solution for your application.