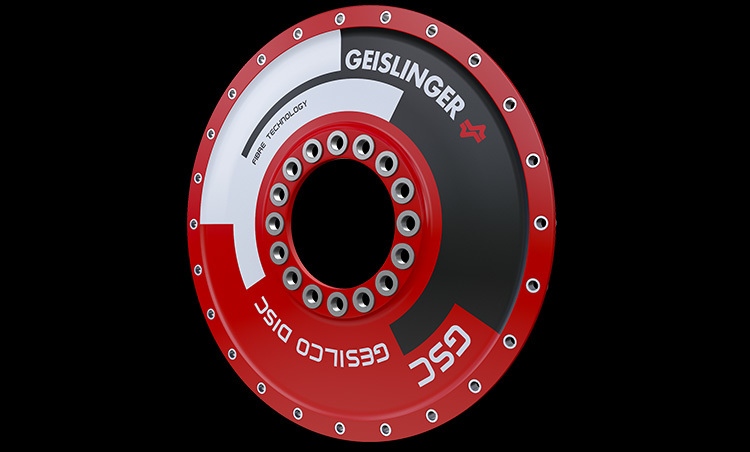

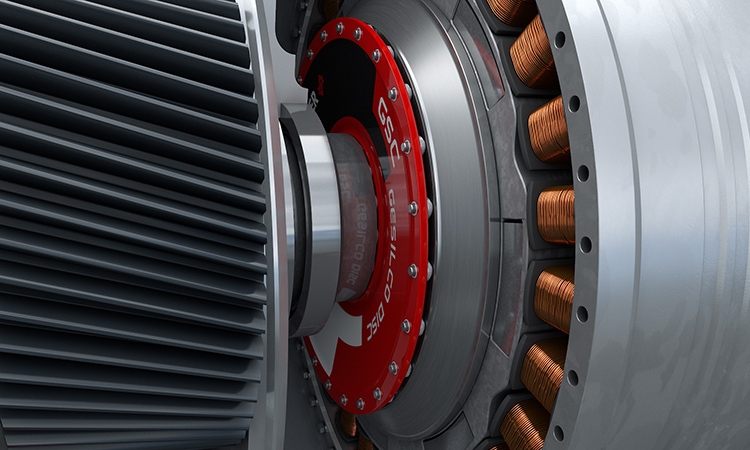

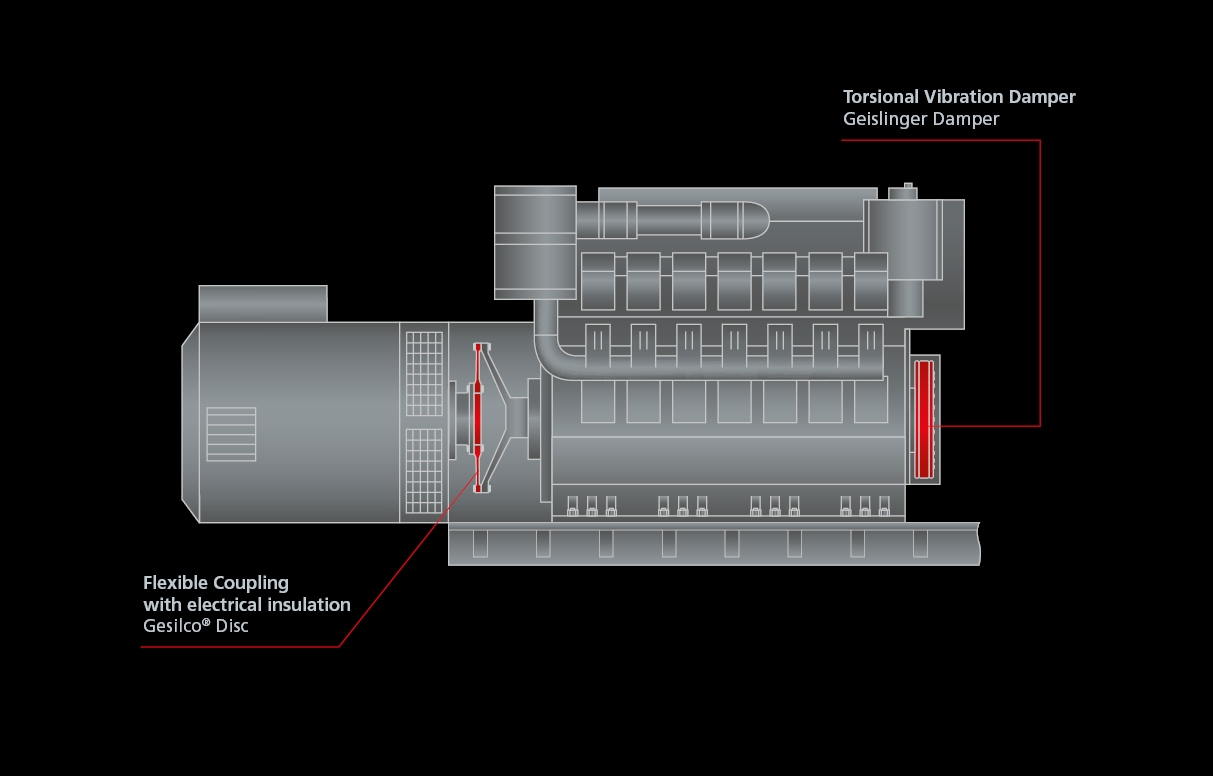

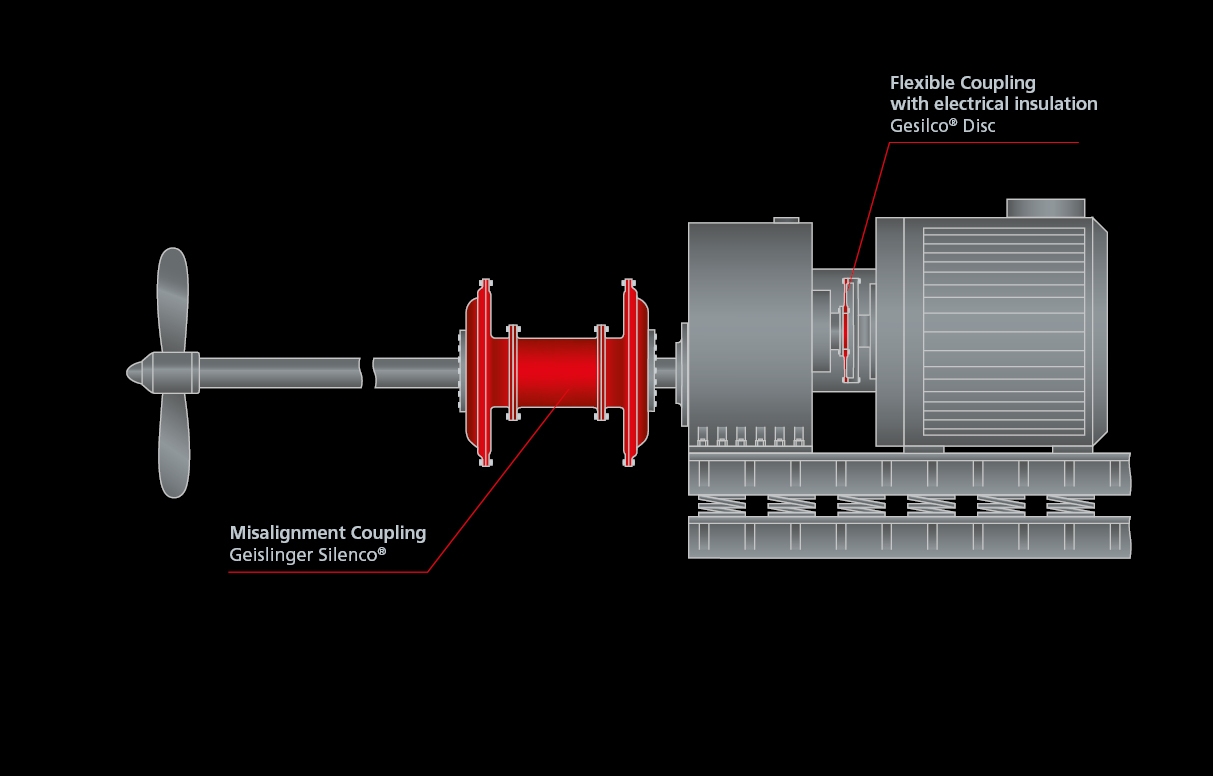

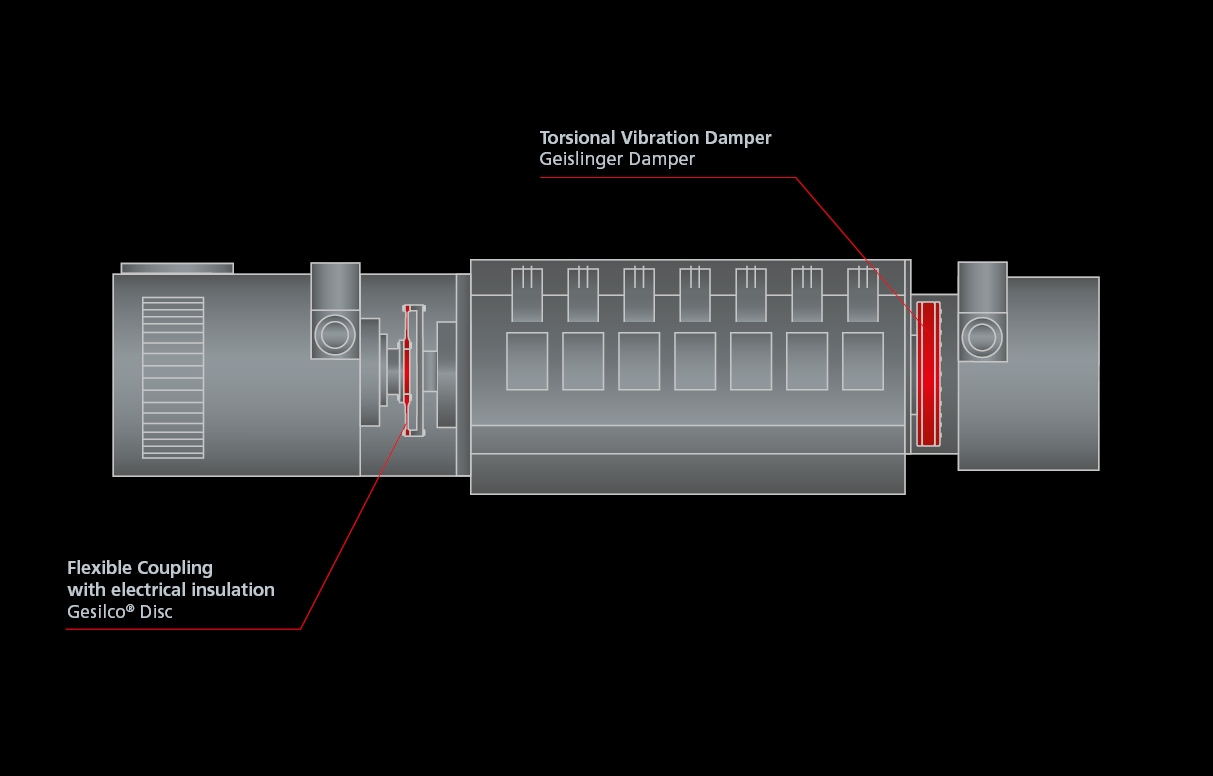

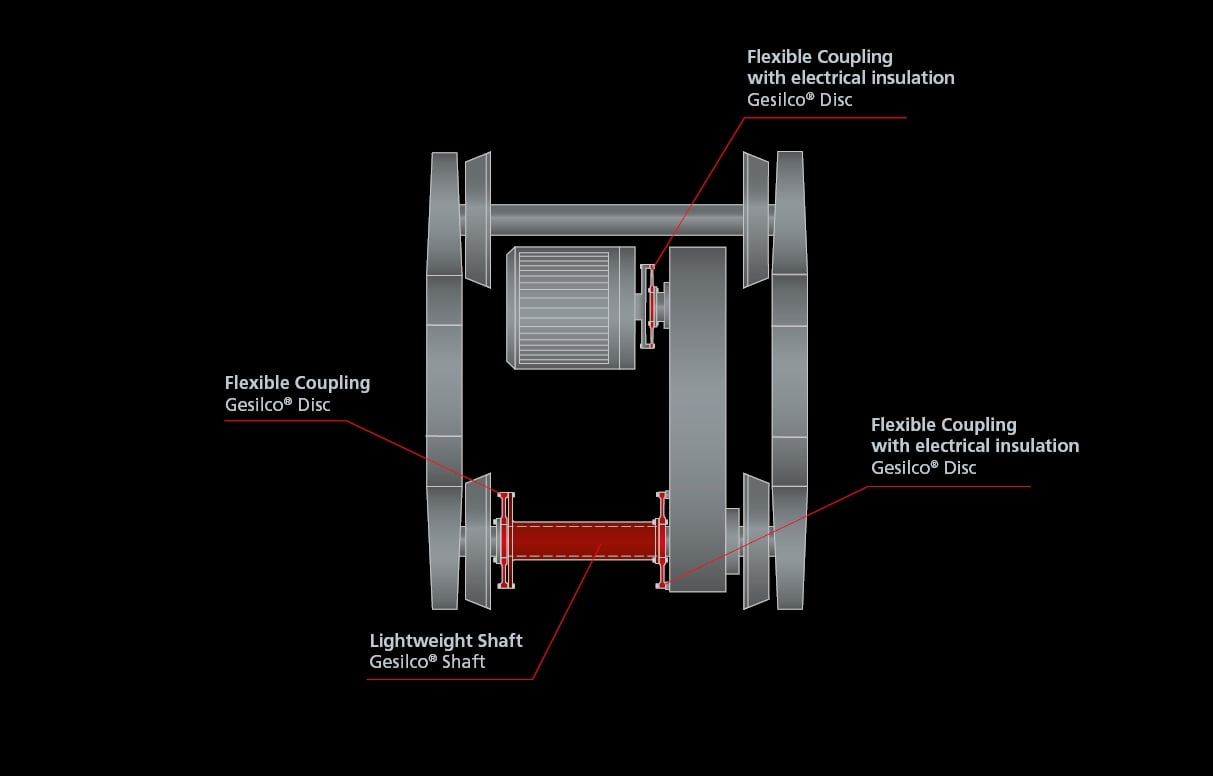

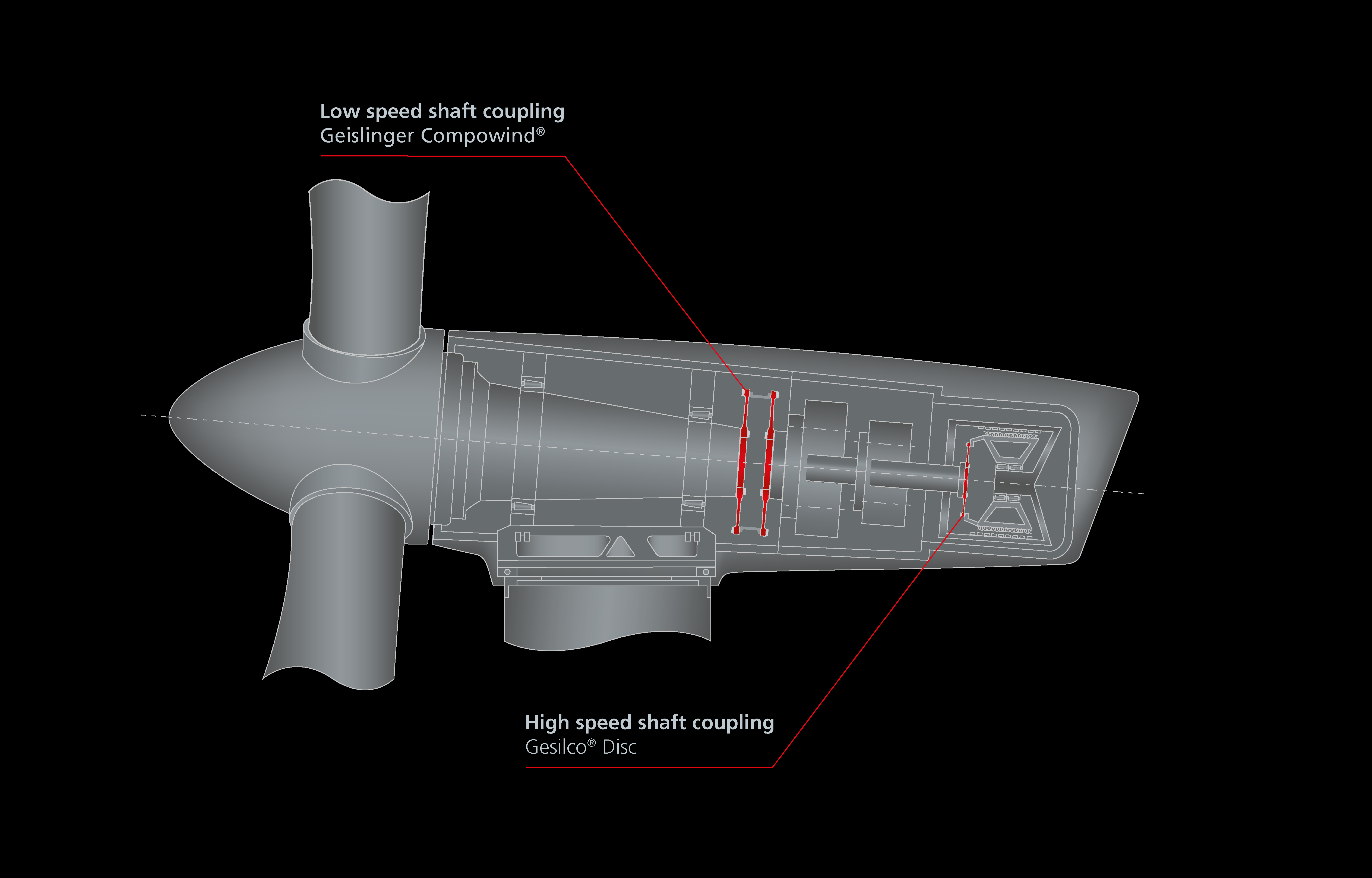

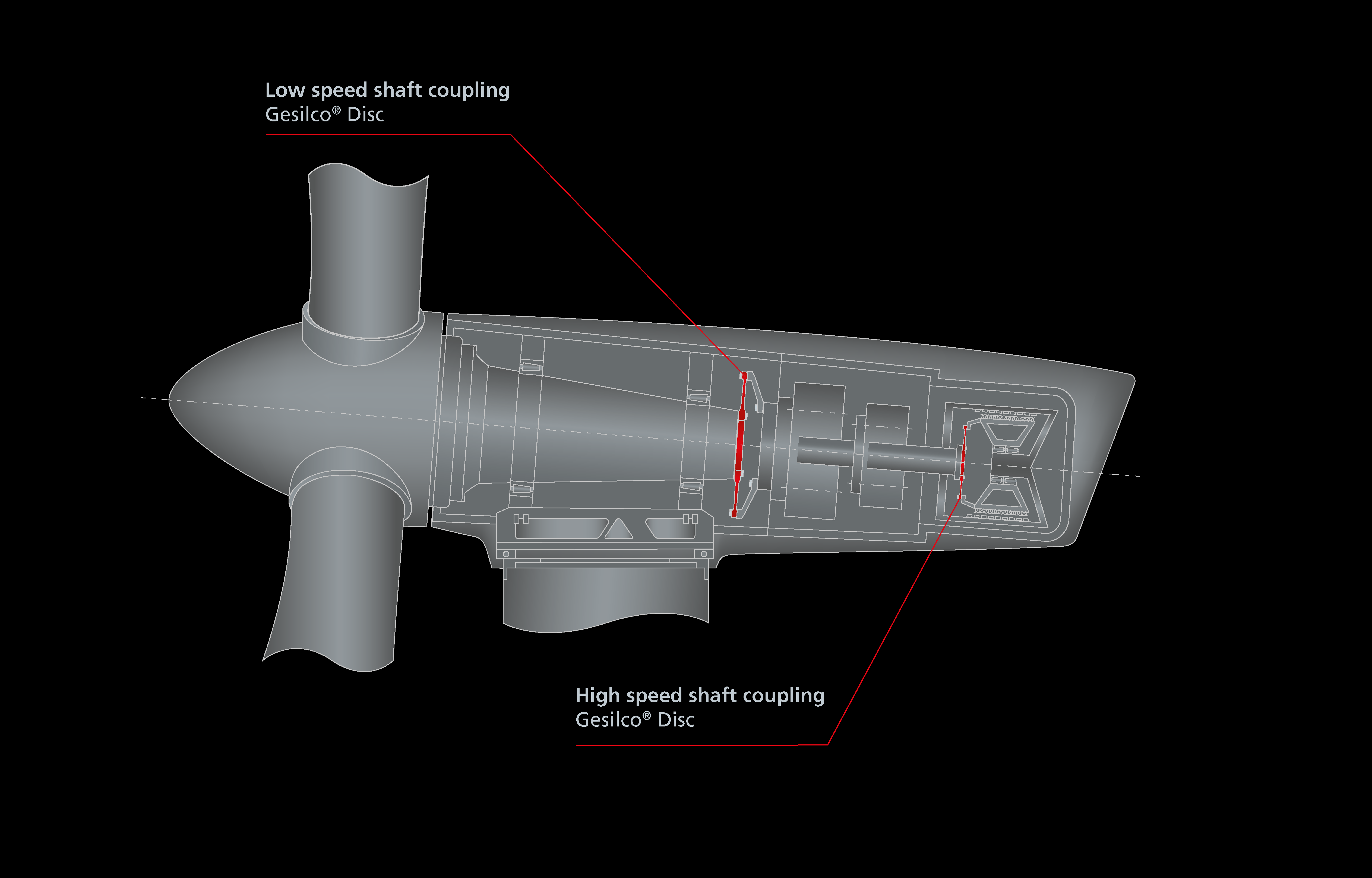

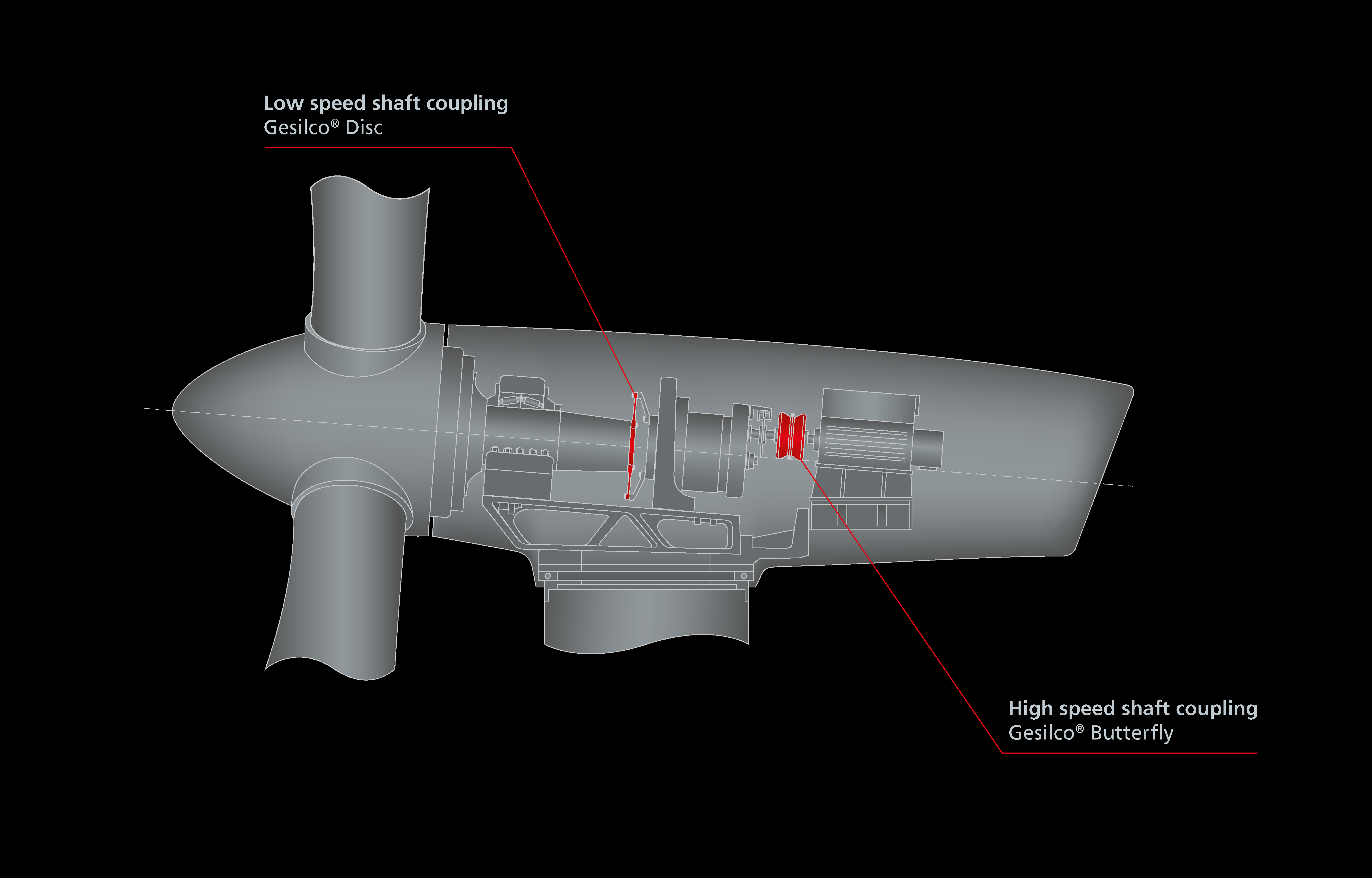

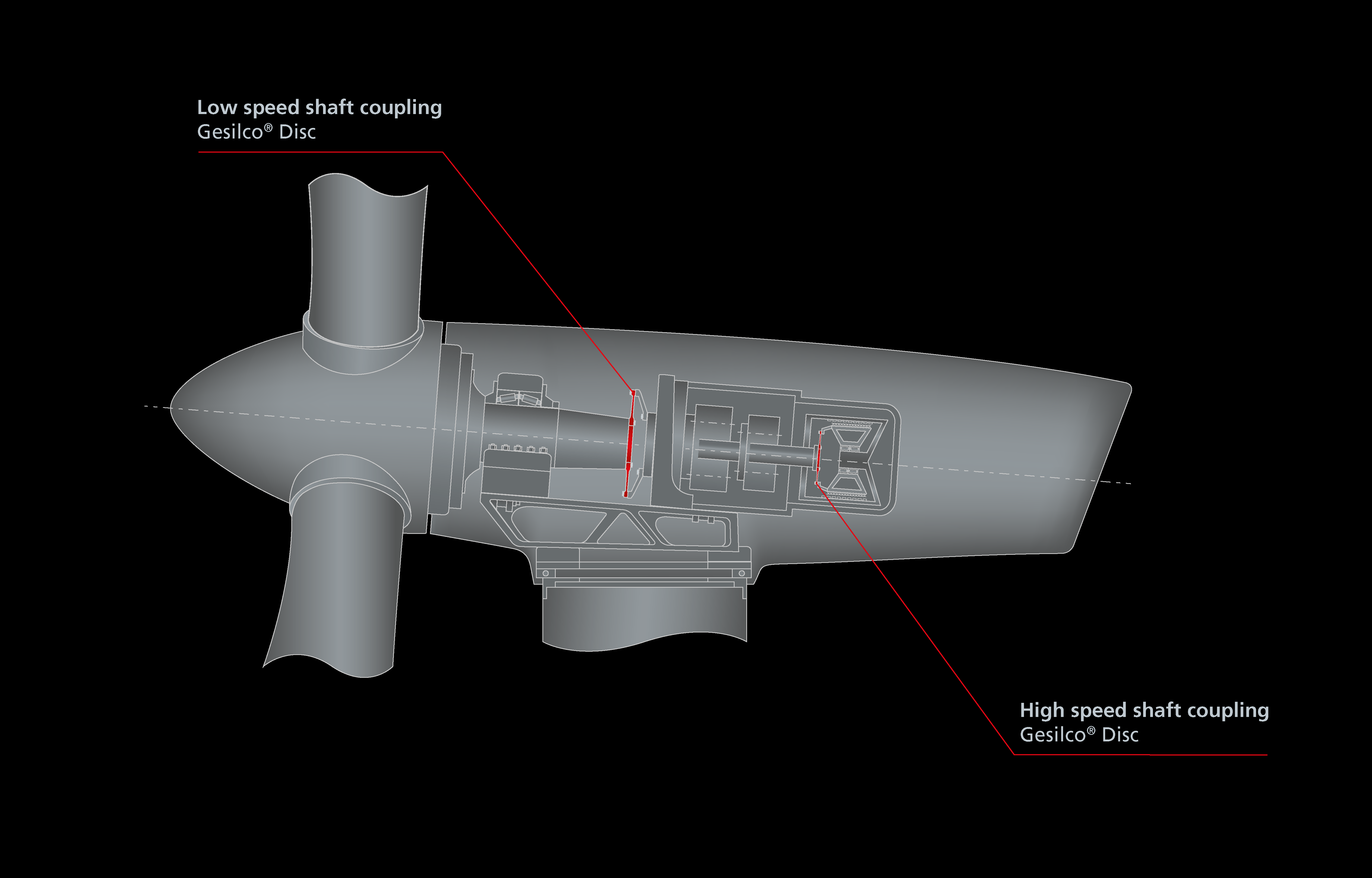

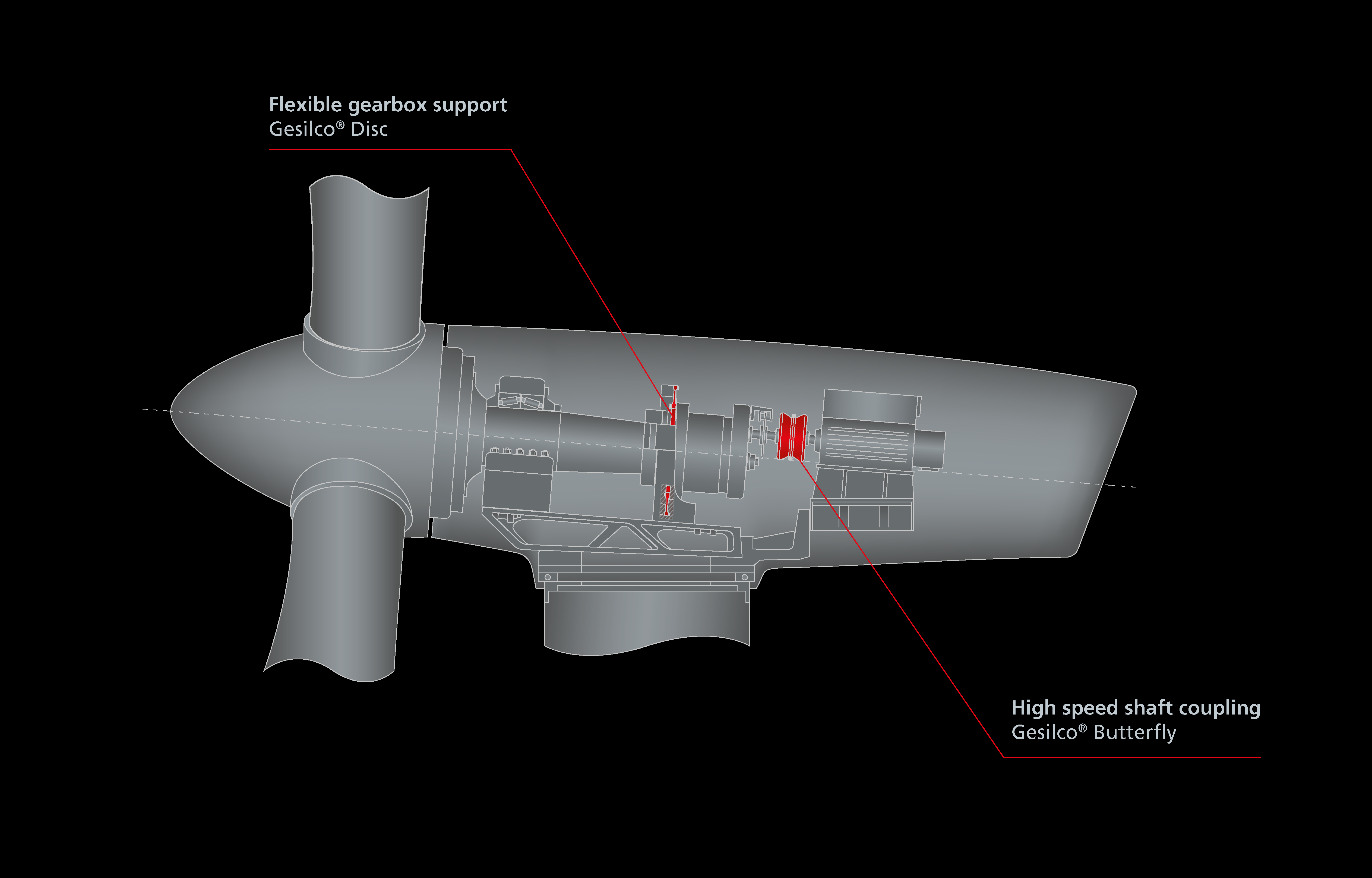

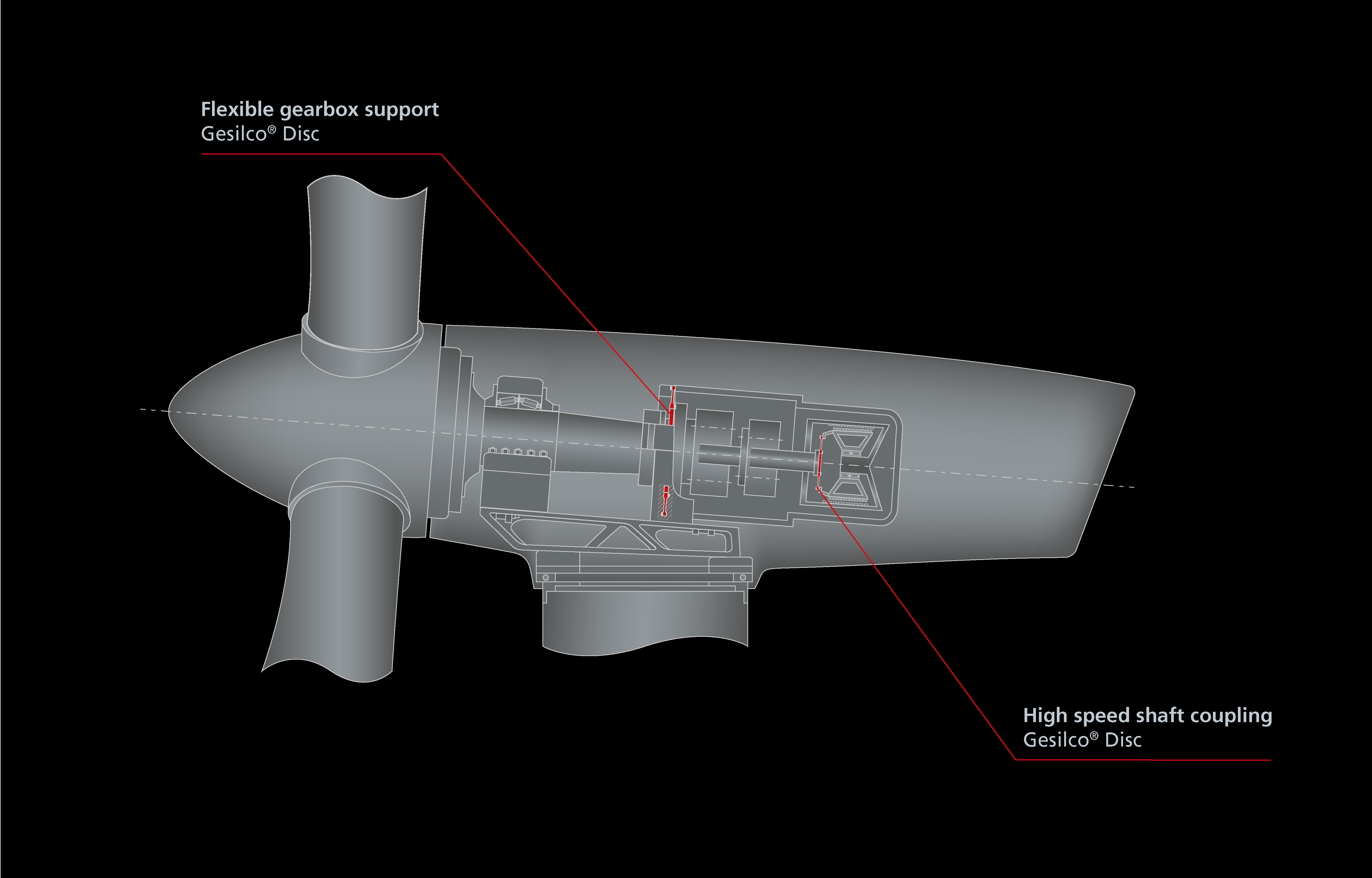

The Geislinger GESILCO® Disc is a coupling for diesel-electric drives. The GESILCO® Disc connects the generator with the combustion engine, isolates the generator from the engine and protects it from potential crankshaft bearing failures through electric corrosion. Furthermore, the electrically insulating GESILCO® Disc is designed for high radial forces while transmitting high vibratory torques with the lowest reaction forces.

A single GESILCO® Disc coupling compensates angular and axial misalignment, and a combination of two membranes enables the compensation of radial, angular, and axial misalignments. The flat membrane is made of advanced carbon and glass fibers. Drivetrain systems benefit from low, almost linear reaction forces as well as from the highest torque transmission with the best dynamic behavior. Further advantages are electrical insulation and non-magnetic properties. Even under extreme conditions, the highest shock resistance of the GESILCO® Disc coupling is a great benefit.