SHARE ON:

Link copied!

On June 22, 2022, Geislinger participated actively at the shipping companies meeting of the German Shipbuilding Society (STG). The event was held at the historic storage building “Schuppen 9” in Lübeck, Germany.

Dr. Andreas Thalhammer, head of the Torsional Vibration Calculation Team, was Co-Author for a presentation given by Prof. Hinrich Mohr about impacts caused by the Carbon Intensity Indicator (CII) on the operation of different ship types, showing solutions for future-proof operation of existing vessels.

It was shown how the CII’s limitations on CO2 emissions have a significant influence on real ship operation. Following 2023, restrictions will become significantly stricter every year, which makes it ever more difficult to stay inside the permitted parameters. As an example, three real cases for existing vessels and different applications were presented. Each showed different insights, potential solutions, and challenges.

The examples showed that engine power limitation (EPL) can keep the vessel CII compliant for a few years only. This can lead more frequently to operational restrictions or result in increased component wear, e.g., due to increased torsional vibrations when passing through barred speed ranges.

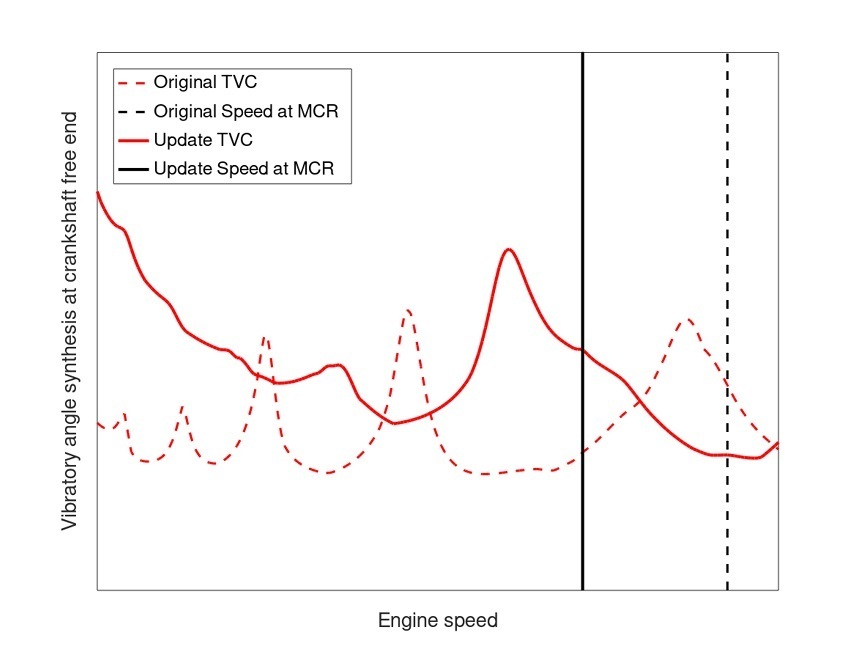

Due to the changed operational profile, EPL strategies are typically accompanied by design optimizations of various components such as a bulbous bow on a new ship or a smaller propeller that is optimized for slow steaming. In general, both a change in operational profile and replacement of major powertrain components can cause a change to different vibration load conditions. The following graph of the vibratory angle synthesis shows the impact of the propeller size for slow steaming at lower engine speed, see the red curve with the updated TVC. This is compared with the original system (dashed red curve, original TVC):

Operational optimization can clearly support the CII tasks, but this will not be sufficient in most cases. Further measures for improving e.g. ship resistance are likely to be required as well. Furthermore, the CII fulfilment requires close operational planning between charterers, owners, and operators. An early and detailed operational data analysis with the involvement of component suppliers and service providers supports the avoidance of issues.

With expertise in Torsional Vibration Analysis and experience with Big Data from Field Data Analysis, Geislinger is available as an active partner to help the ship operators to solve these issues: Geislinger Digital Solutions’ newly implemented, cloud-based Geislinger Analytics Platform (GAP) uses big data analysis in combination with information from the Geislinger Monitoring System to enable predictive analysis and anomaly detection. Furthermore, it enables ship operators and technical staff to remotely gain insights into vessel and fleet performance. Features such as shaft power and vibration monitoring, along with efficient data storage, are key to meeting upcoming CII regulations. Learn more about how Geislinger Digital Solutions help support future-proof marine powertrains.