WELCOME TO THE FUTURE OF POWERTRAIN MONITORING.

Geislinger Digital Solutions combine excellent product performance with world-class engineering to provide additional operational reliability, reduced costs, and optimized performance for your powertrain or even your fleet.

Geislinger Digital Solutions' two core units, the Geislinger Analytics Platform (GAP) and the Geislinger Monitoring System Mk6 (GMS Mk6) are our industry-leading software and hardware solutions that work together to provide continuous measurement of your dynamic system behavior and a cloud-based data push.

This enables features like trend analysis, AI-powered anomaly detection, rapid troubleshooting, data analysis, reporting, predictive maintenance, and many more.

Monitoring your drivetrain with Geislinger Digital Solutions ensures maximum safety, prevents downtime, mitigates overall operational risk, and provides a solid foundation for fuel savings and ultimately a reduction in CO2 emissions, helping you future-proof your vessel and fleet.

Key features of

Geislinger Digital Solutions

Trend Analysis

Due to a continuous monitoring of the application a trend analysis can be made.

GMS Mk6 enables us to analyze historical data and look at possible changes over time. The experts in our torsional vibration department can analyze your system and create a predictive maintenance model. This leads to a better service planning, less downtime and less maintenance costs.

Fleet Management

Easy and smart fleet management - One look gives you all the information.

The interactive overview dashboard enables you to keep control of your complete fleet. AI supported anomaly detection and the automated notification system enable maximum operational safety, reduced cost and optimal performance.

Autonomous operation

The remote access and continuous push of data guarantee maximum safety and supervision.

Artificial intelligence can be used for decision-making and keeping the system under remote control.

Anomaly detection

For detecting operational anomalies and short-time deviations from the expected performance, the Geislinger Analytics Platform provides an anomaly detection.

For this, artificial intelligence models are trained after certain times in operation that continuously compare predicted and real performance data to each other.

Connectivity

The analytics platform coupled with the GMS Mk6 offers a smart solution to blend its data into any platform.

Data integration from different sources and data exchange of valuable systems can easily be adapted into the offering of the platform.

Safety & support

The Analytics Platform establishes a direct line to Geislinger Services for troubleshooting and remote services.

The data push to the platform enables us to quickly check your system in case an alarm was triggered on the monitoring system. Experts can access the monitoring and investigate the vibrations curves to support you with valuable insights for better operations. Thus, the downtime of your system is minimized, and the operational risk is reduced.

Digital twin

Physical parameters can be benchmarked against a simulation from the torsional vibration data to analyze discrepancies that may occur during operation.

Additionally, the continuous measurement outcomes and corresponding analysis enrich simulations which allows the Geislinger Service team to give predictive and condition-based maintenance advice.

Reporting

Based on the gathered data our torsional vibration department can analyze the system and create a report on the condition of the system that can be used for class associations or insurances.

Reports provide additional safety, less operational risk and can be used for class association confirmation.

SUCCESS STORY

Already dozens of customers rely on Geislinger Digital Solutions to monitor the drivetrain and improve the longevity and efficiency of their vessels or fleets.

One of the most notable implementation of Geislinger Digital Solutions is the December 2021 collaboration with shipping company CPO Containerschiffreederei: After successfully conducting a pilot installation on the MSC La Spezia (one of the ships of the so-called "Italian Fleet" named after Italian cities), monitoring the torsional vibrations of the main propulsion system with a MAN 2-stroke engine through the Geislinger Mk6 and implementing the Geislinger Analytics Platform, CPO announced that it will proceed with the installation of Geislinger Digital Solutions on the rest of its fleet, which includes 8 vessels.

LEARN MORE

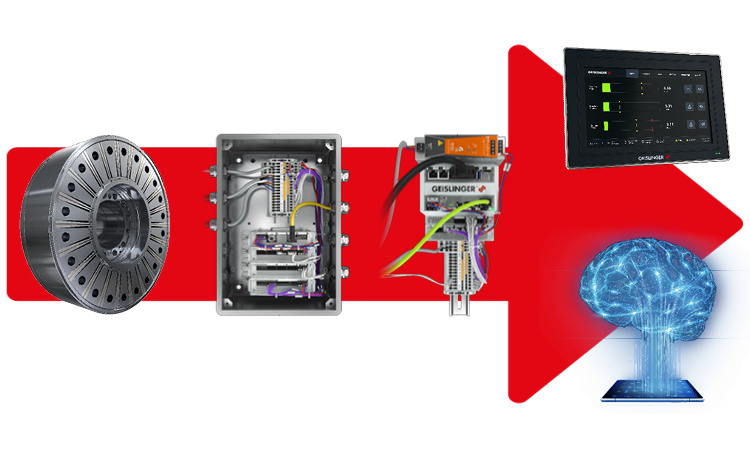

DATA FLOW

All Geislinger Digital Solutions units work hand in hand to retrieve, analyze and deliver important data about your powertrain and its components.

Sensors attached to dampers, couplings and shafts measure their performance and relay this data to the system unit via the junction box. The processed data is then sent both to your vessel's Mk6 for display to your crew and to the Geislinger Analytics Platform, where you can access it from any device, anywhere in the world.

MONITORING SOFTWARE

The Geislinger Analytics Platform (GAP for short) is the brain of Geislinger Digital Solutions.

This cloud-based online monitoring platform for torsional vibrations and continuous measurements enables predictive analysis and anomaly detection. It combines Big Data applications with Geislinger's extensive engineering expertise. Customers can access the Geislinger Analytics Platform and the Geislinger Monitoring System from any computer or mobile device via a web interface. The Geislinger Analytics Platform is fully hosted by Geislinger and our main focus is to ensure maximum data security as all data flows through our secure domain.

LEARN MORE

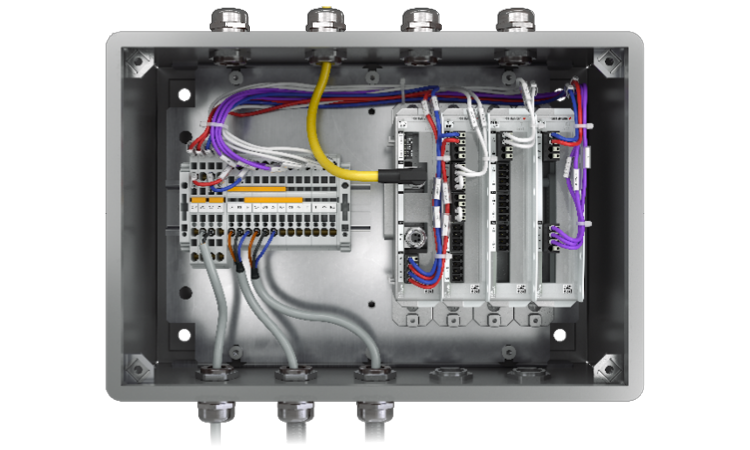

MONITORING HARDWARE

The Geislinger Monitoring System Mk6 (GMS Mk6 for short) is the embodiment of our hardware solution that goes hand in hand with the Geislinger Analytics Platform.

The GMS Mk6 is the gateway to the digital world. It can monitor torsional vibrations throughout the powertrain and predict failures by detecting abnormal behavior early. The connectivity and data acquisition of the new GMS Mk6 enables Big Data analytics and machine learning. The GMS Mk6 is often used in conjunction with Geislinger torsional vibration dampers and flexible couplings. Its main task is to monitor the components and detect functional deviations on site. A variety of physical interface options guarantee a flawless connection to third-party systems.

LEARN MORE

YOUR PARTNER

Want to learn more about Geislinger Digital Solutions?

Our experts will be happy to support you when it comes to powertrain digitalization and how Geislinger Digital Solutions can help optimize the powertrain monitoring of your ships or fleets.

REACH OUT