Advantages

- Additional operational safety, low running costs and increased service life due to problems being detected early

- Reduction of unplanned downtimes and thus significant cost savings

- Simple monitoring of torsional vibrations

- Modular design, easily expandable

- High level of connectivity, for integration into the ship’s network or existing AMS

- Cloud-based online monitoring of torsional vibrations and permanent measurements due to the access to the Geislinger Analytics Platform

- Automated data acquisition and corresponding data analysis: Switch from periodic to condition-based maintenance

- Geislinger Worldwide After Sales Service

Technical data

- Self-monitoring system unit with a malfunction alarm

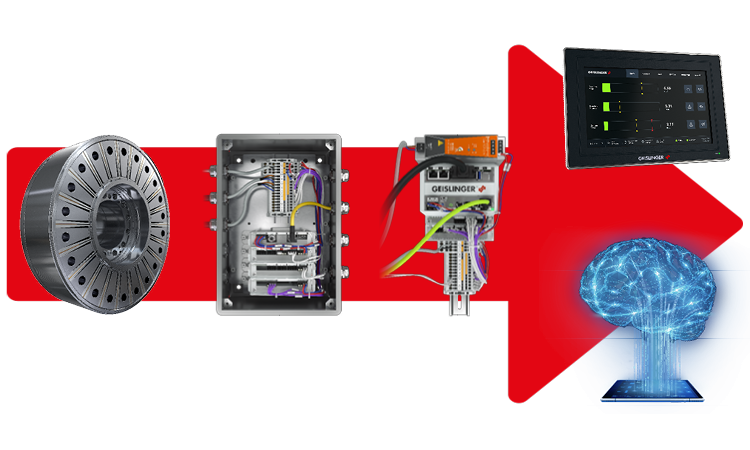

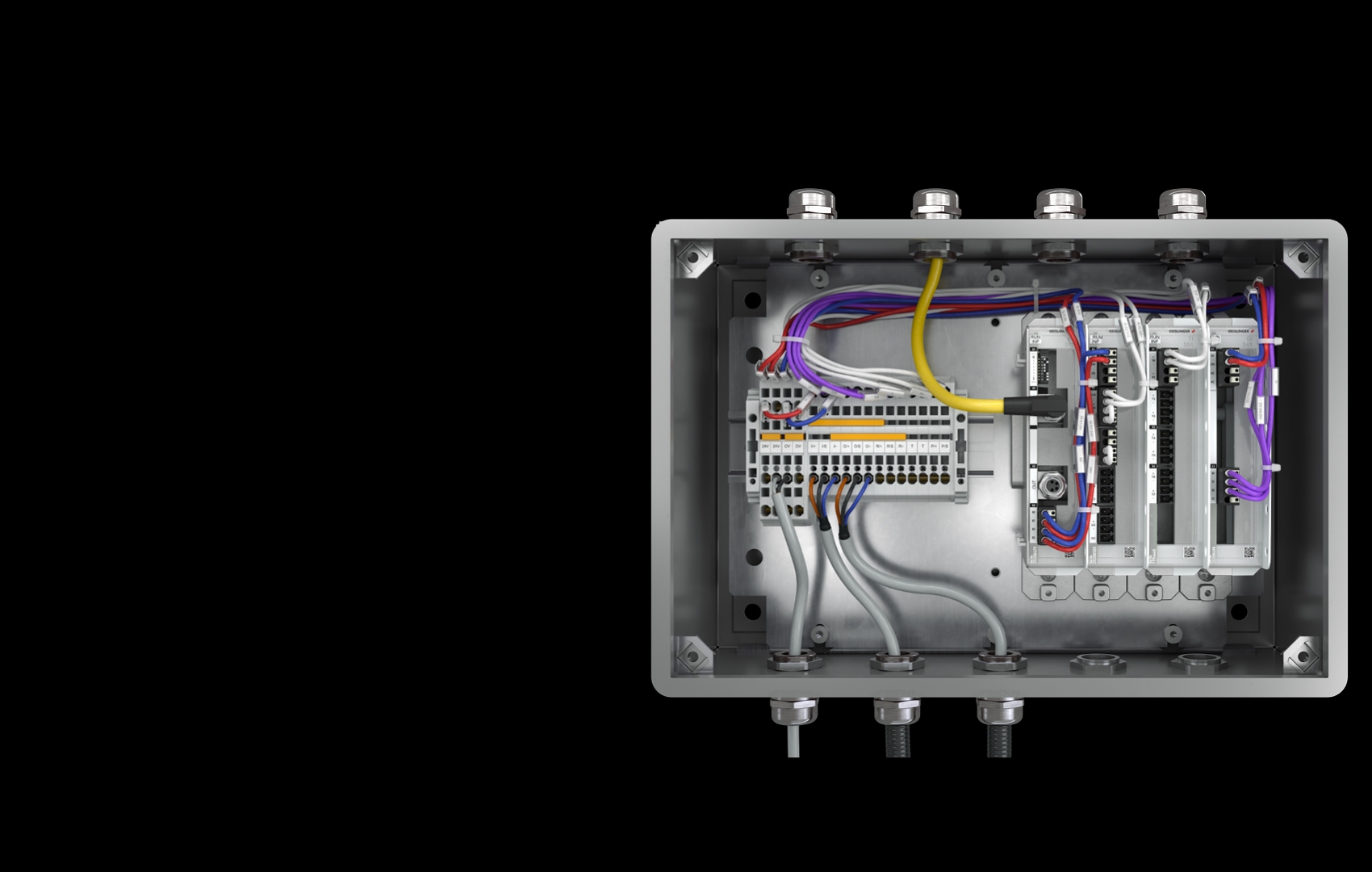

- System Unit (IP20), Junction Box (IP65), Operator Panel (front IP65, back IP20)

- Electrical and environmental testing according to IACS E-10 rules and type approval from DNV GL

- 24 V DC power supply, overvoltage protection

- State-of-the-art connectivity options

- Physical interfaces: 1x USB 3.0 for data acquisition, 1x EtherCAT, 2x Gbit Ethernet for ship network integration, Micro SD, 1x DVI, 1x CAN, 1x RS 232/422/485

- Supported Ethernet-based protocols: Modbus TCP, HTTP / HTTPS / WebSocket, OPC UA. Additional protocols are available on request (MQTT, SSH, SCP, FTP, …)

- 6 potential-free relay switches for alarm output (4 x opener and 2 closers)

- 4 analogue output (4 – 20 mA), resolution 12 bit (1x Buzzer connected)

- Maximum operating temperatures: 55°C

- 24 V DC power supply, overvoltage protection

- Maximum operating temperatures: 70°C

- 4 digital inputs

- 4 analogue inputs

- Temperature measurement unit: 4 inputs, supported resistance sensor types NTC, PT 100, PT 1000, NI 100, NI 1000

- TFT-Display with touchscreen

- (7” TFT-LCD, 1.024 x 600 Pixel) Maximum operating temperatures: 55°C 24 V DC power supply

- DVI / RFB

- Height: 135 mm, Width: 200 mm, Depth: 27 mm, Weight: 1,1 kg

- Inductive or hall sensors

- Temperature sensors (PT100)

- Pressure sensors (4 – 20 mA)

Applications

- Geislinger Analytics Platform: Cloud-based online monitoring platform of torsional vibrations and permanent measurements allowing for predictive analysis and anomaly detection.

- Misfiring (free-end) Monitoring: If a cylinder misfires, the alarm signal can be used as a warning to reduce the engine load or to disengage a clutch to avoid excessive vibration levels and further subsequent damage.

- Crankshaft stress or intermediate shaft stress monitoring: Monitoring a critical order range of the vibratory angle at the free end of the crankshaft can be used for detecting dangerous operating conditions for crankshafts or other driveline components.

- Damper Monitoring: Monitoring the damper twist ensures trouble-free operation of Geislinger dampers.

- Coupling Monitoring: Static and dynamic twists are calculated; both the power transmitted and torque are displayed.

- Shaft and Power Monitoring: Engine output and shaftline vibrations are displayed to optimize fuel consumption and increase the propulsion safety level.

- Oil Pressure and Temperature Monitoring: Sensors inside the Geislinger oil supply are available as an option for 2-stroke applications. Multiple Product Monitoring: Multiple Geislinger products can be monitored on one or several engines.