GEISLINGER ANALYTICS PLATFORM

The Geislinger Analytics Platform is a cloud-based online monitoring platform for torsional vibrations and continuous measurements of powertrain components.

Using proprietary artificial intelligence, the analytics platform combines Big Data applications with Geislinger's extensive technical expertise.

The platform is fully hosted by Geislinger and our main focus is to ensure maximum data security as all vessel and fleet data flows through our secure domain. In combination with the Geislinger Monitoring System Mk6, Geislinger Digital Solutions enable some of the following functions.

FUTURE FUELS & SUSTAINABILITY

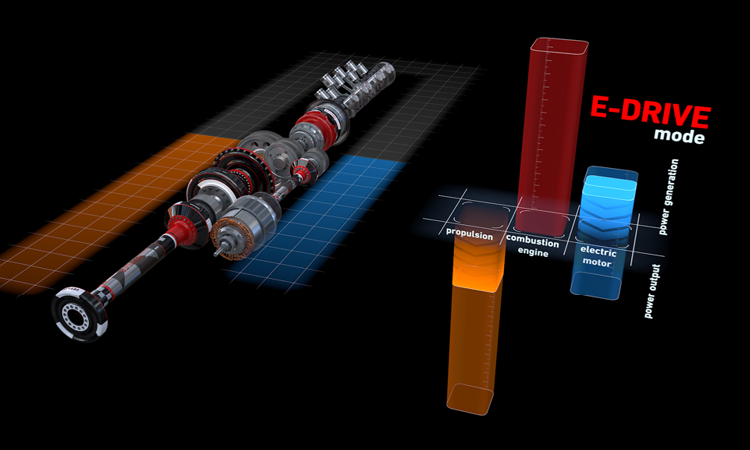

The shipping industry is increasingly required to take action to reduce CO2 emissions. Regulations such as CII, EEXI and EEDI are forcing the industry to look for new innovations. Hybridization is already proving to be a viable alternative for some applications, but there is another possible answer: future fuels.

However, different fuels result in different torsional vibrations and therefore different loads on your powertrain. As a torsional vibration expert, we can guide you through customized retrofit processes based on simulation, measurement data and our experience to future-proof your vessels and fleets.

REDUCED TOTAL COST OF OWNERSHIP

Maintenance costs make up a large part of fleet operators' budgets. The artificial intelligence system developed in-house by Geislinger Digital Solutions offers many tools for optimizing maintenance processes.

From making maintenance intervals more flexible, to remote and online maintenance support, to online system updates - all these features help our customers save valuable time and other resources.

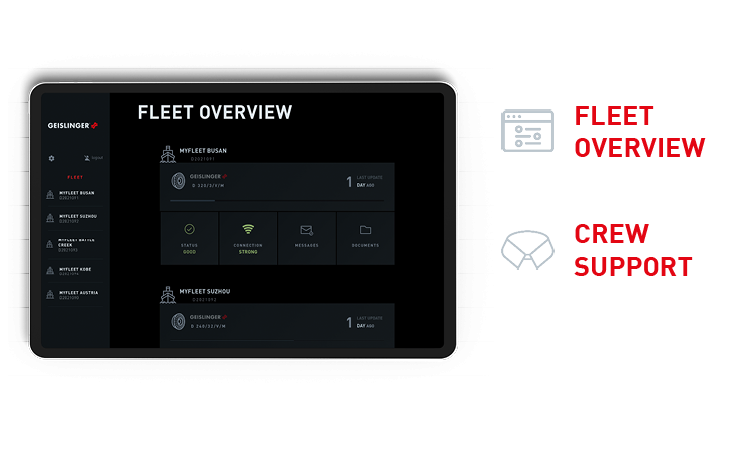

FLEET OVERVIEW AND CREW SUPPORT

Our interactive fleet management overview gives our customers real-time control over their entire fleet. AI-powered anomaly detection and an automated notification system enable maximum operational reliability, optimal performance and reduced costs.

These performance improvements can be shared with your fleet's crews - allowing your teams to drive your vessels to peak performance and improve efficiency at the same time. The data can also be used for many other purposes, such as preparing customized training tailored to your crews and your ship's needs.

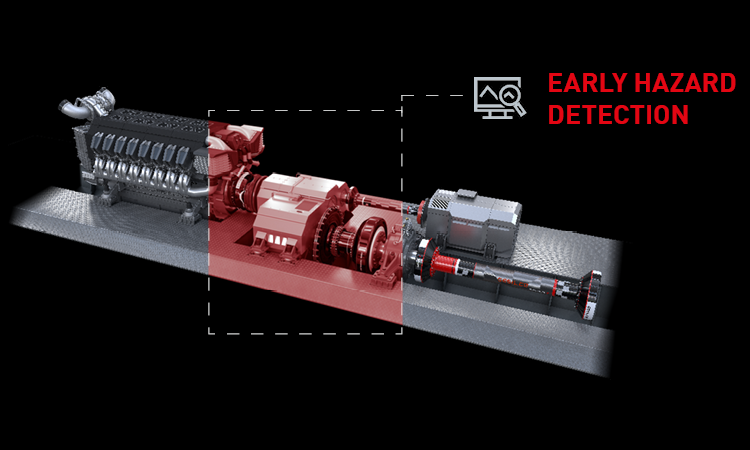

MAXIMIZED RELIABILITY

Preventing critical failures in the powertrain is a key feature of Geislinger Digital Solutions and provides the most valuable benefit to our customers.

Continuous monitoring of powertrain components allows us to analyze historical data, take a close look at possible changes over time, and identify potential hazards at an early stage.

Our torsional vibration experts can use all the data to analyze our customers' system and create a predictive maintenance model - ensuring better service planning, less downtime and lower maintenance costs.

CONNECTIVITY

For the maritime industry, online data exchange is a key factor for success in the near future.

With its all-time connectivity, Geislinger Digital Solutions continuously retrieves data from our customers' powertrain and transfers it to the Geislinger Analytics Platform for permanent monitoring.

This data is used by Geislinger Digital Solutions' artificial intelligence for decision-making and keeping the system under remote control. Thanks to its connectivity, Geislinger Digital Solutions can also act as one of the key drivers for the development of autonomous vessel operation.

MORE FEATURES

REPORTING

Based on the data collected, our torsional vibration department can analyze the system and produce a report on the condition of the system that can be used for class associations or insurance. The reports provide additional assurance, reduce operational risk, and can be used for class association confirmation.

DIGITAL TWIN

Physical parameters can be compared with a simulation from the torsional vibration data to analyze discrepancies that may occur during operation. In addition, the continuous measurement results and the corresponding analyses enrich the simulations, enabling the Geislinger service team to make predictive and condition-based maintenance recommendations.

SAFETY & SUPPORT

The Geislinger Analytics Platform provides a direct connection to Geislinger Services for troubleshooting and remote maintenance. The data push to the platform allows us to quickly check your system if an alarm has been triggered on the monitoring system. Experts can access the monitoring and examine the vibration curves to help you with valuable insights for better operation. This minimizes your system downtime and reduces operational risk.

AUTONOMOUS OPERATION

Remote access and continuous transmission of data guarantee maximum security and monitoring. Artificial intelligence can be used for decision making and remote control of the system.

RETROFIT OPTION FOR OLDER MONITORING SYSTEMS

An easy-to-use data upload option is integrated in the Geislinger Analytics Platform, which enables fast data transfer from previous Geislinger Monitoring System generations such as the GMS Mk4 or GMS Mk5 and for offline installations of the GMS Mk6. After the manual upload, all functions of the Geislinger Analytics Platform (incl. reporting and dashboard solutions for visualizations) are also available for the uploaded data.