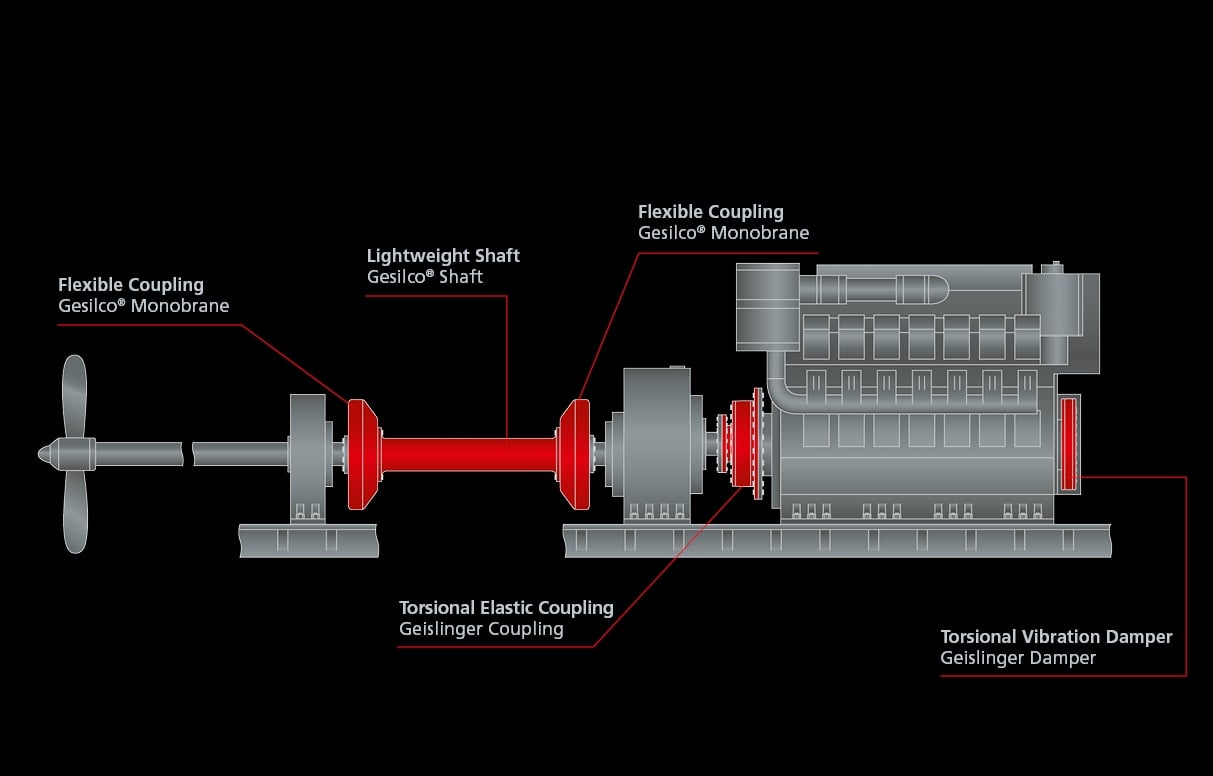

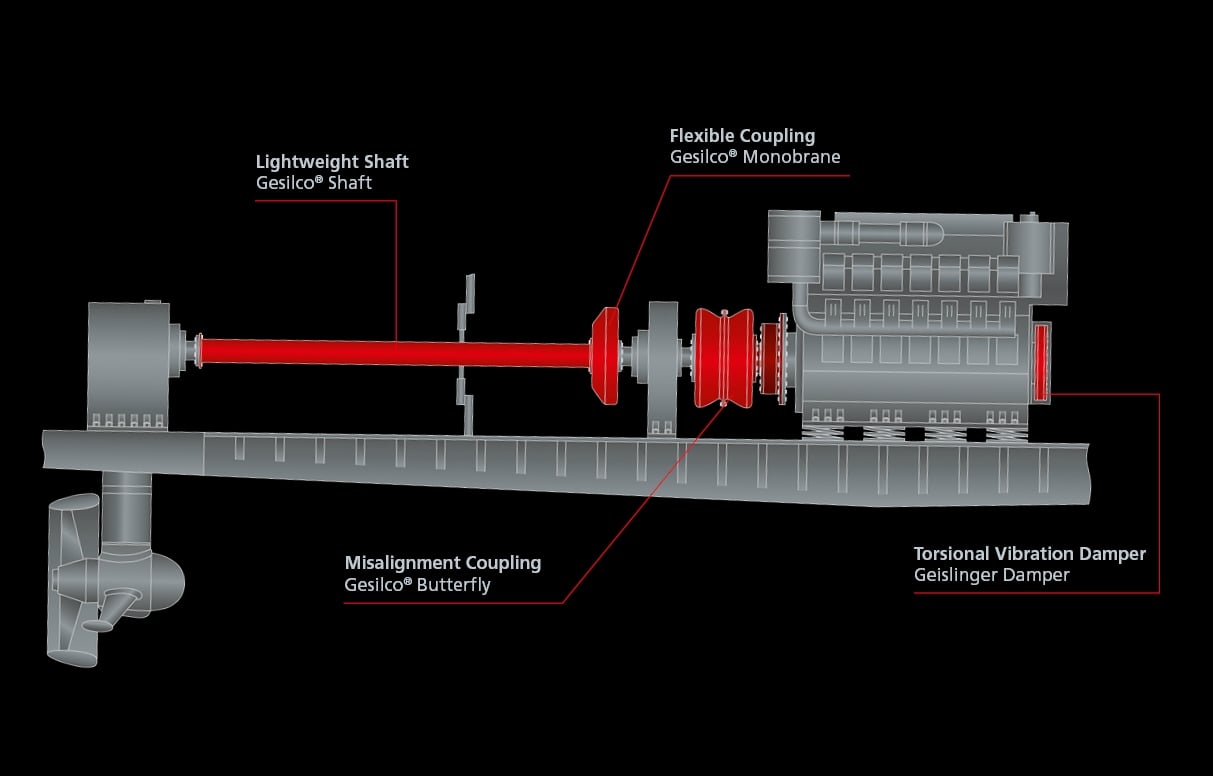

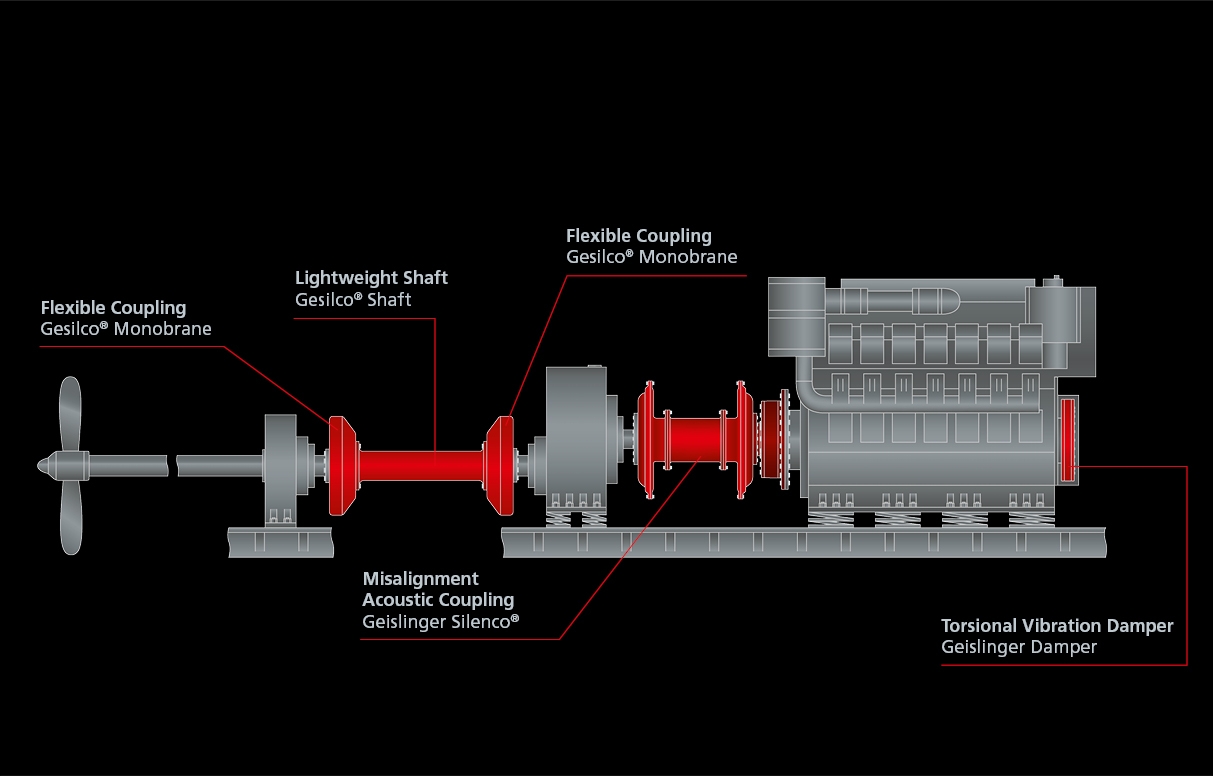

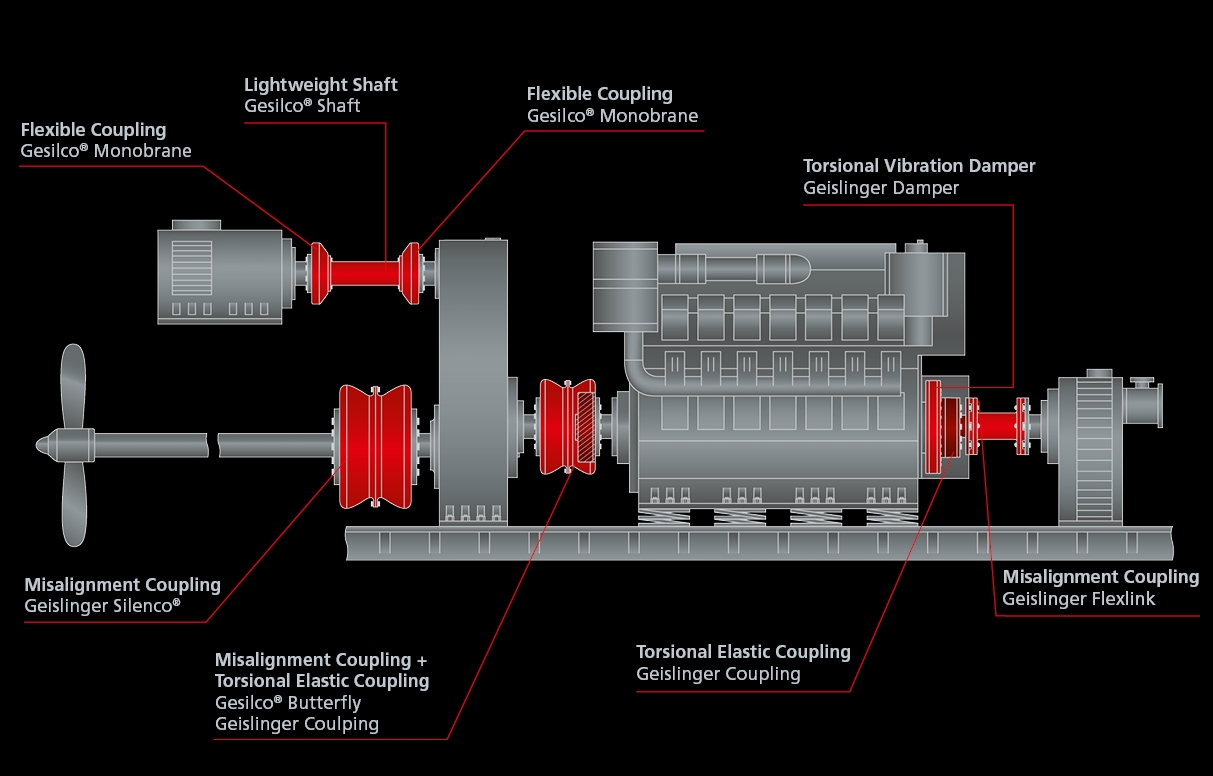

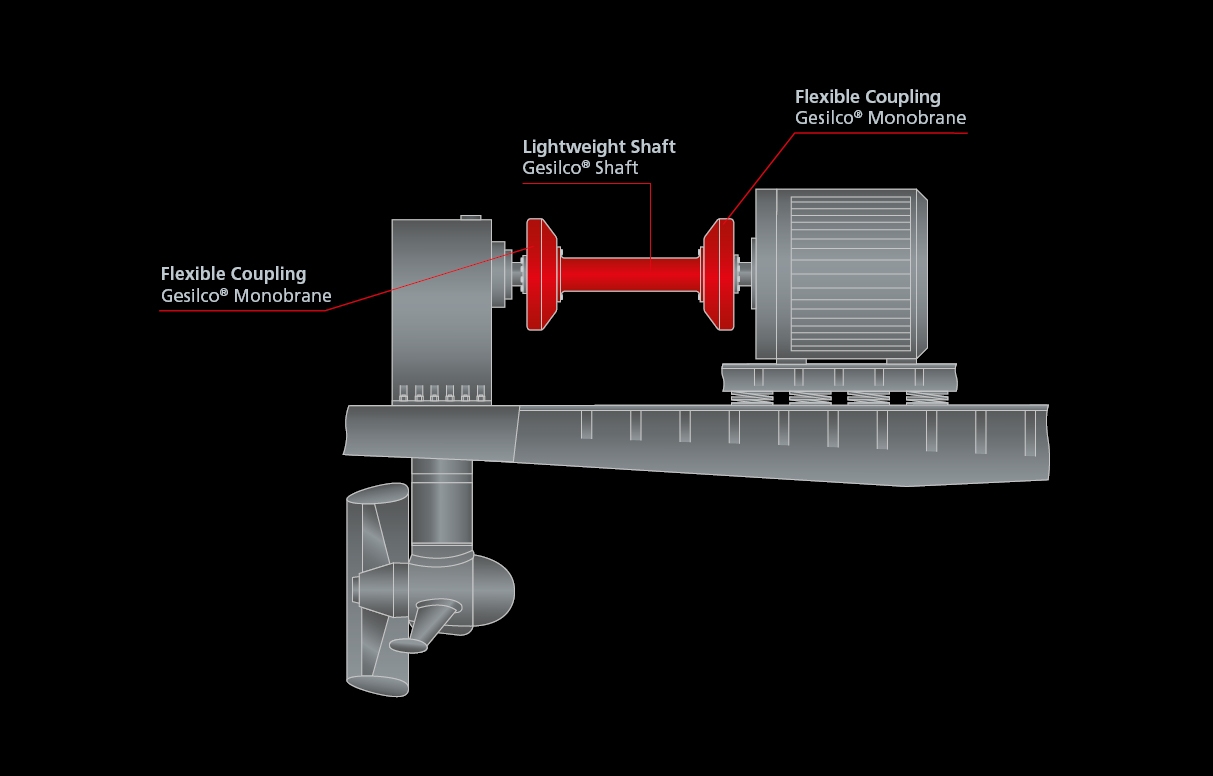

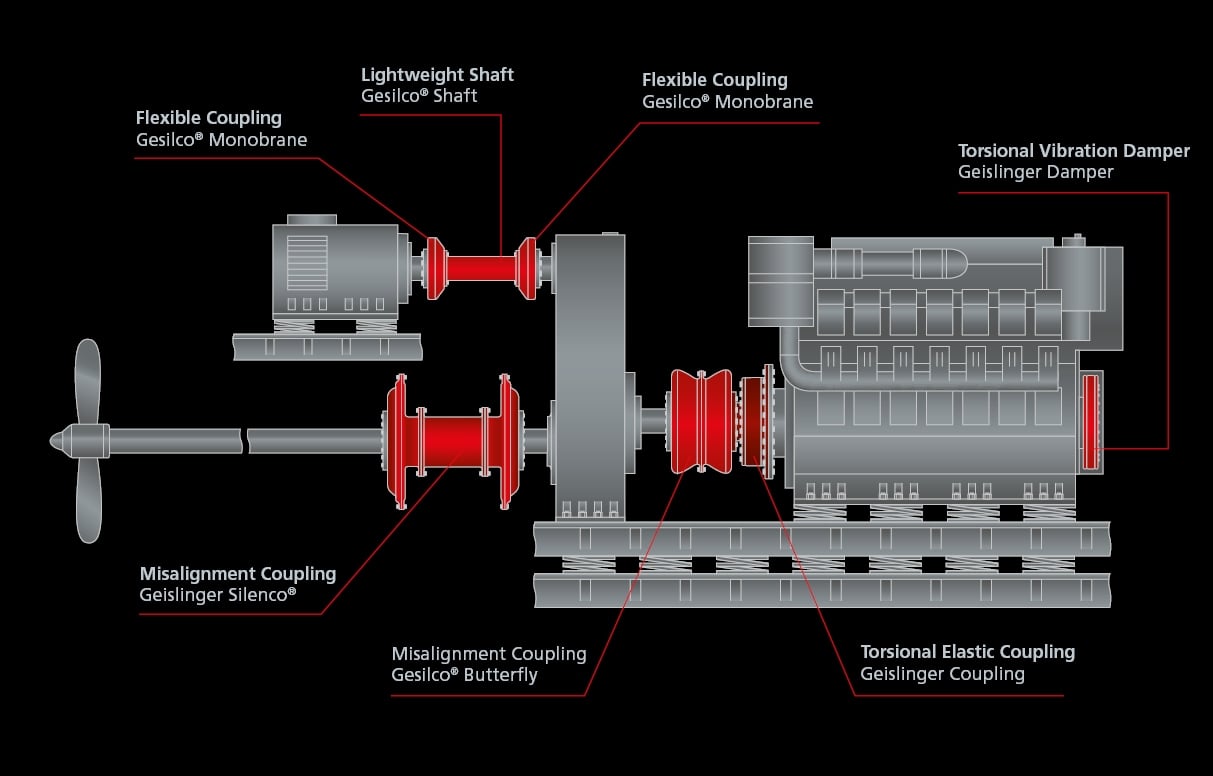

Geislinger GESILCO® shafts are produced in one piece, meaning that the flange is not additionally linked to the shaft, but is already a part of it. This unique design reduces the weight by approximately 50% compared to steel shaft solutions. Due to its modular concept, the GESILCO® Shaft can be adjusted and tailored to applications depending on their specific requirements especially in terms of transmitted power, length, bending stiffness and torsional stiffness. The stiffness levels of the shafts can be adjusted by altering the fiber orientation. The GESILCO® shafts can be produced up to 12 meters in length. The lightweight shaftlines show superior stability throughout its lifetime.

GESILCO® shafts, in combination with GESILCO® couplings, offer outstanding design solutions for lightweight drivelines with excellent deflection compensation capabilities and are suitable for a wide range of applications.