VDAMP® for Wind Turbines:

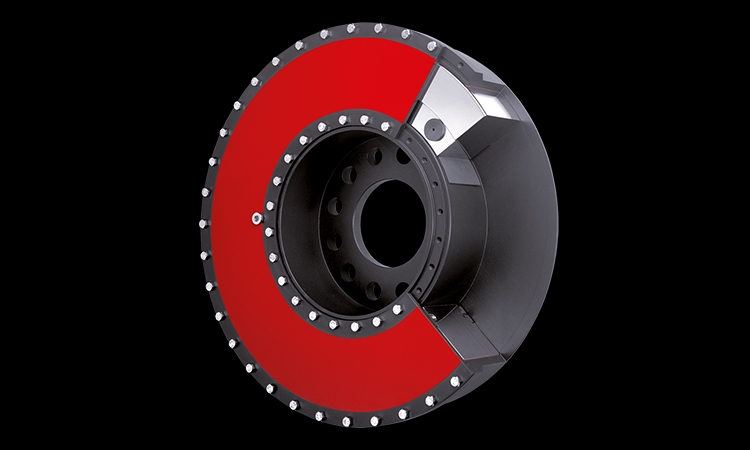

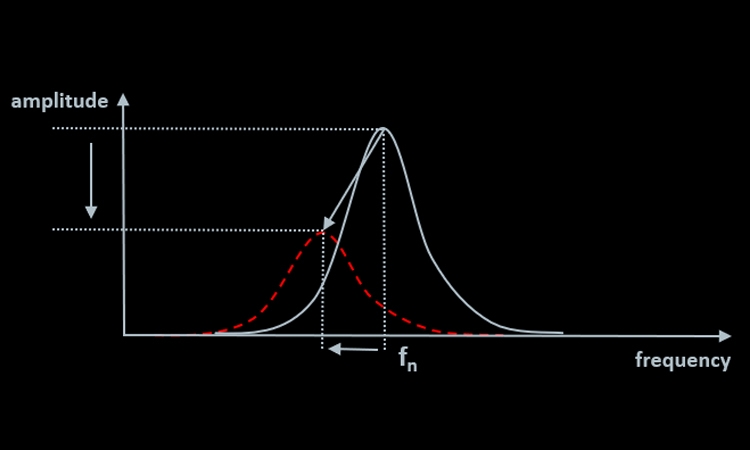

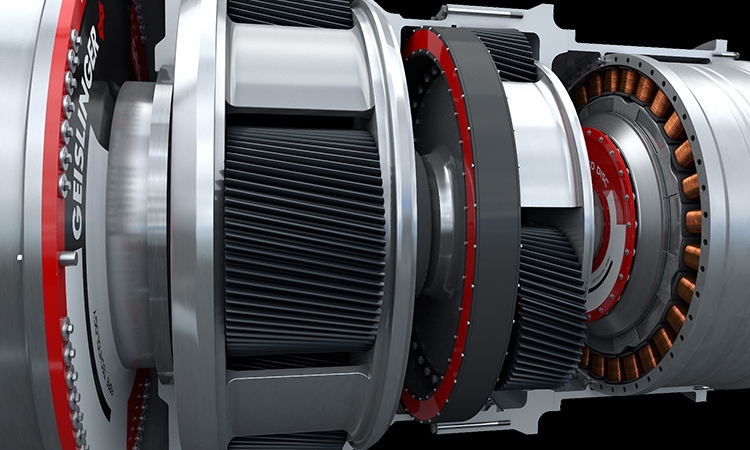

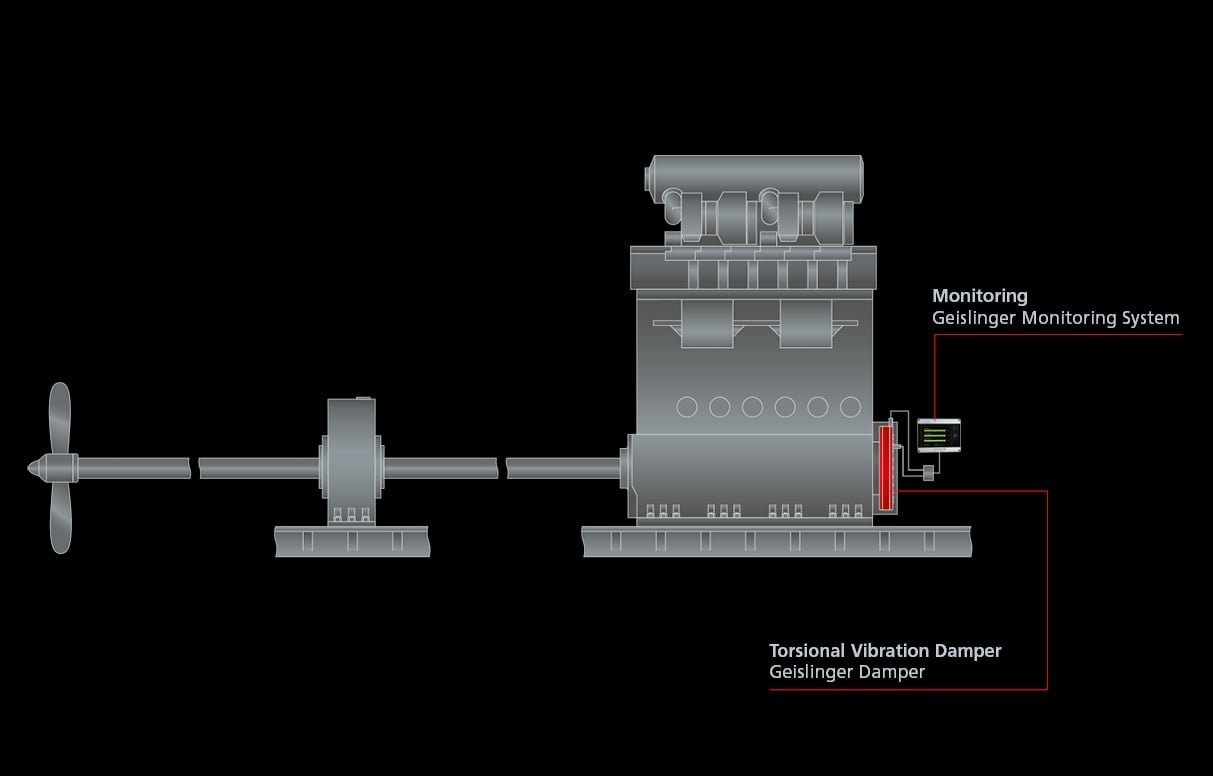

With vast improvements in the aeroacoustics blade design over the past years, the mechanical noise of the wind turbine is becoming more and more audible. Together with the growing sizes of onshore turbines, more stringent regulations, and low wind speed operations, drivetrain noise and tonality has become more challenging. Geislinger VDAMP®, a broad-band torsional damper, gear-integrated or attached to the rotor of a direct-drive turbine, dampens torsional excitations caused by gear teeth mesh, respectively at the pole transition. The torsional vibrations causing the structure-borne noise, which is transferred to the entire wind turbine structure, are dampened effectively at their origin. Wind turbine tonalities can be avoided, and overall sound pressure is reduced.