Advantages

- Increase of driveline lifetime

- Constant performance, no aging

- Low total cost of ownership (TCO)

- Tailor-made coupling

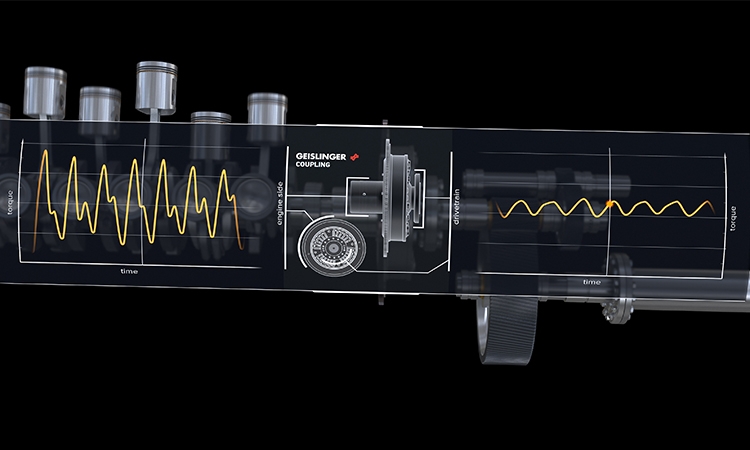

- High-damping

- Long service life

- Oil- and heat-resistant

- Damping and stiffness can be optimized individually

- Low axial reaction forces

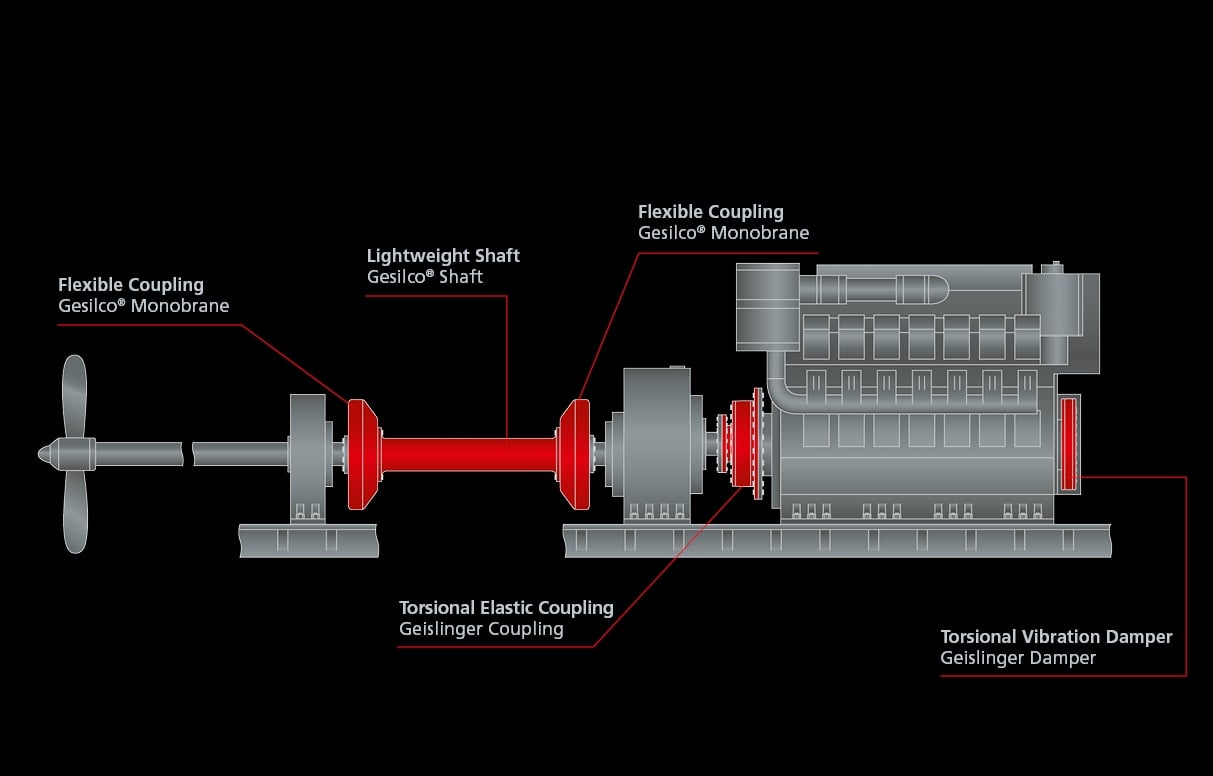

- The most compact design

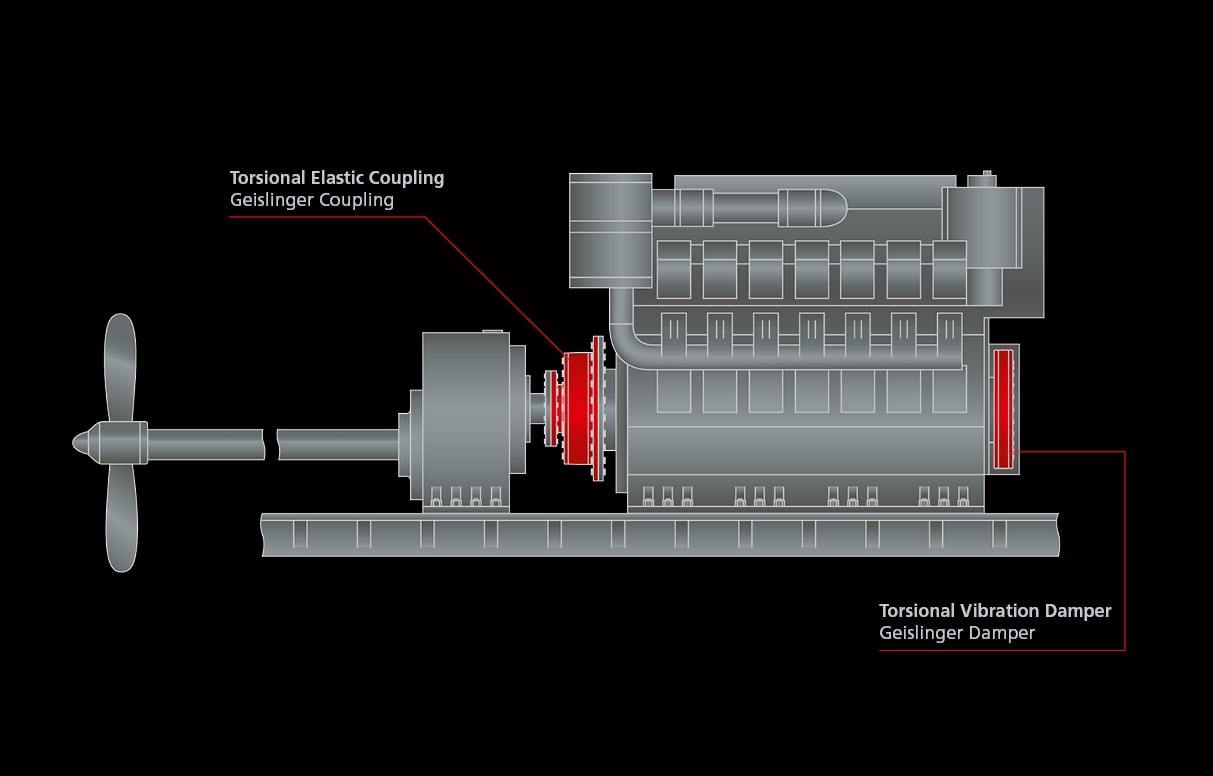

- Integration in flywheel and gear possible

Technical data

- Torque range: virtually unlimited torque

- Twist at nominal torque: 50 - 300 mrad

- Dimensionless damping factor: 0.2 – 0.5

- Ambient temperature: -10°C to 120°C

- ATEX certification

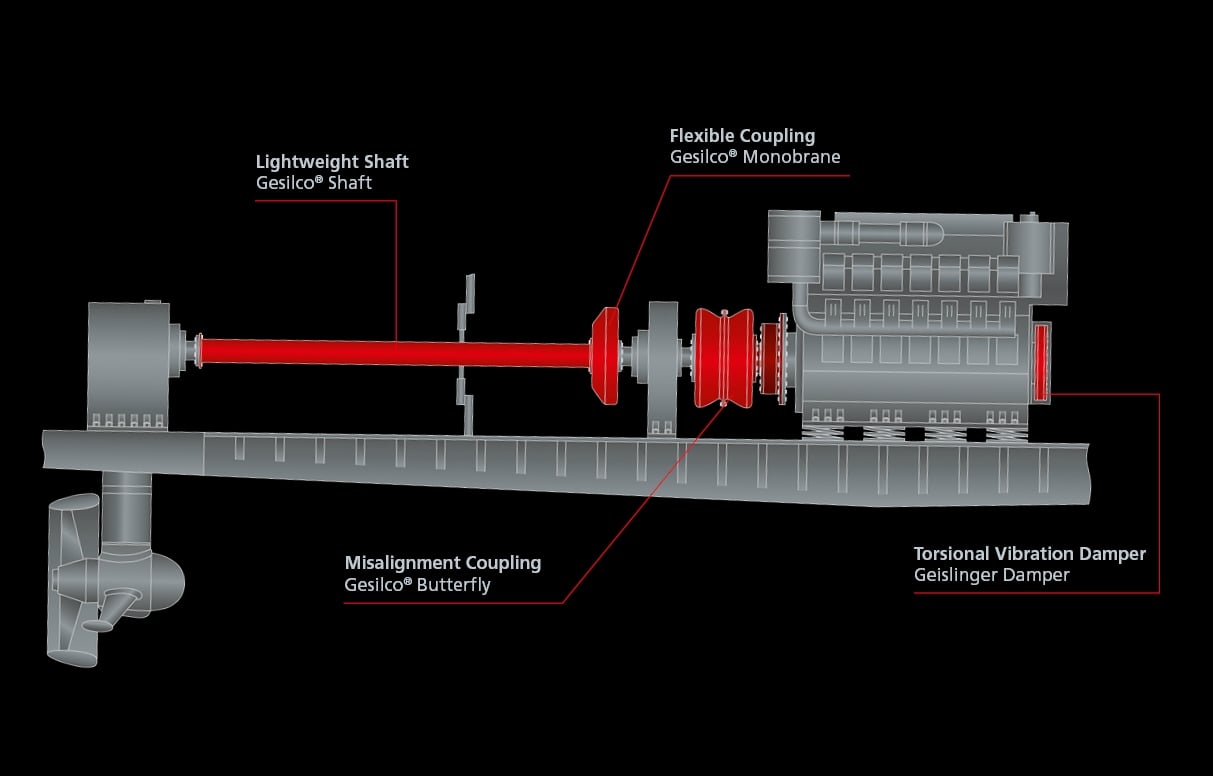

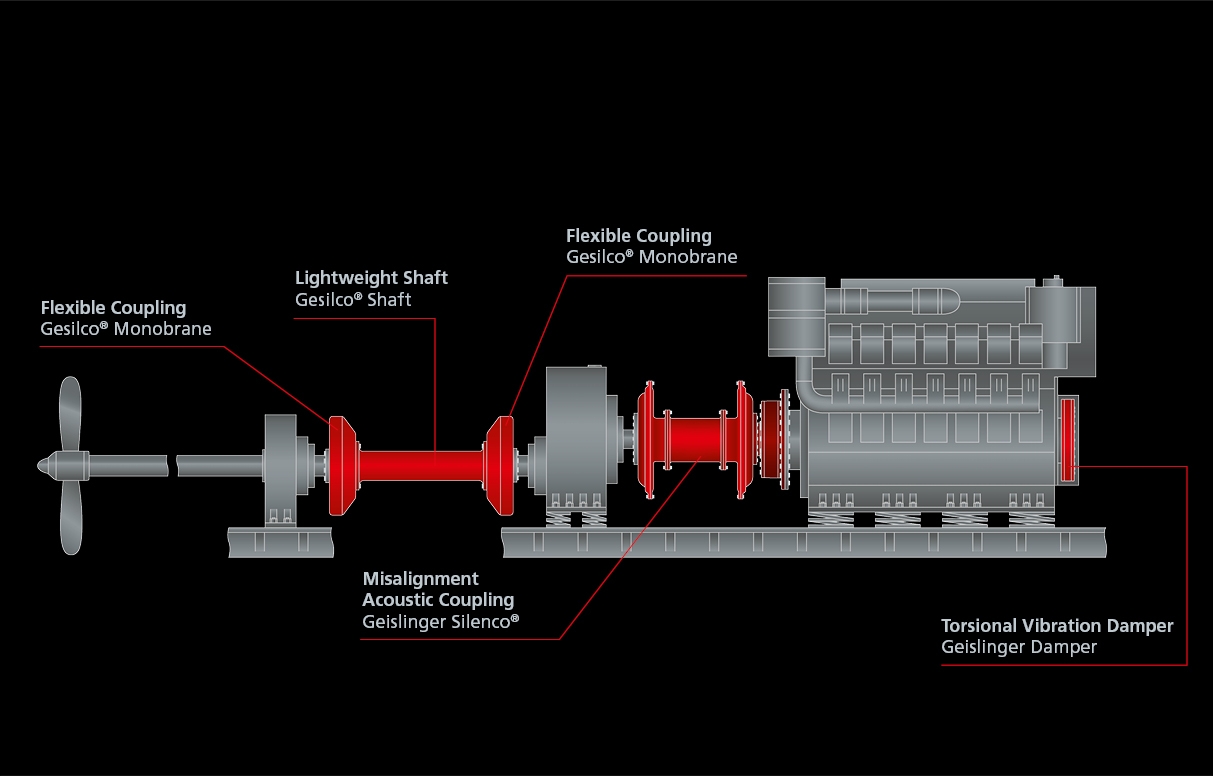

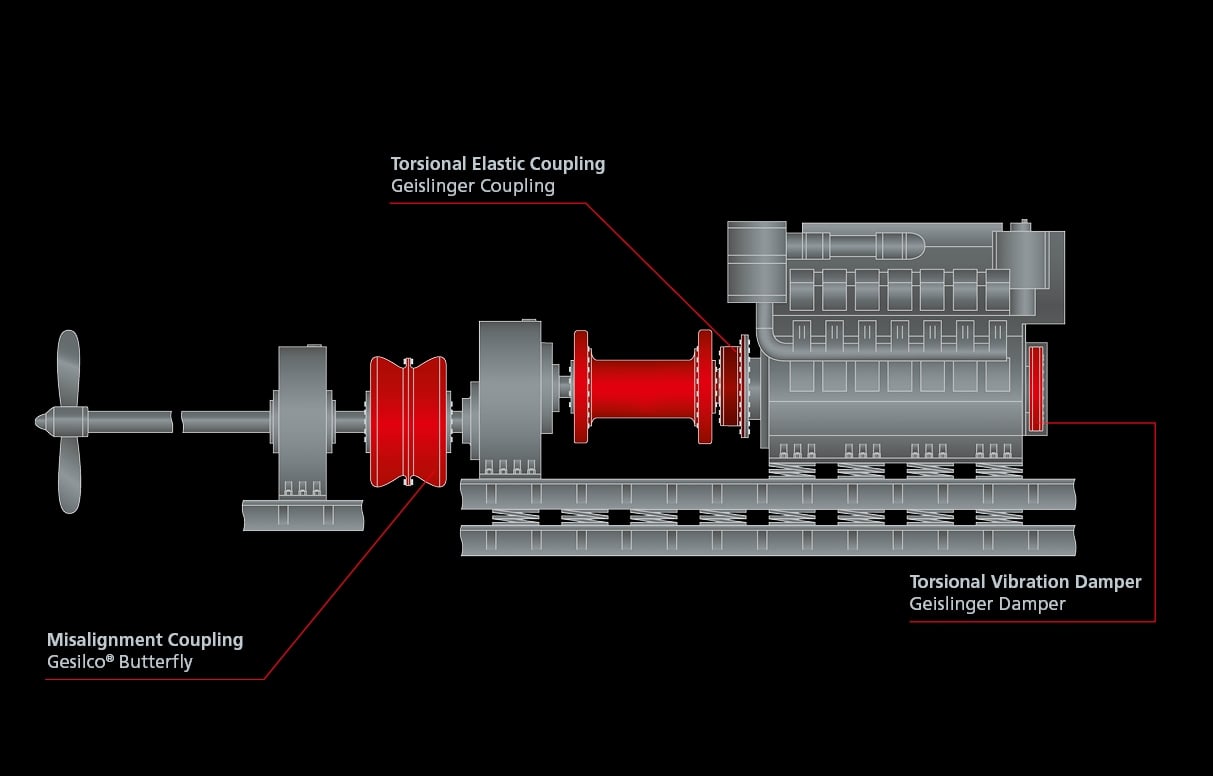

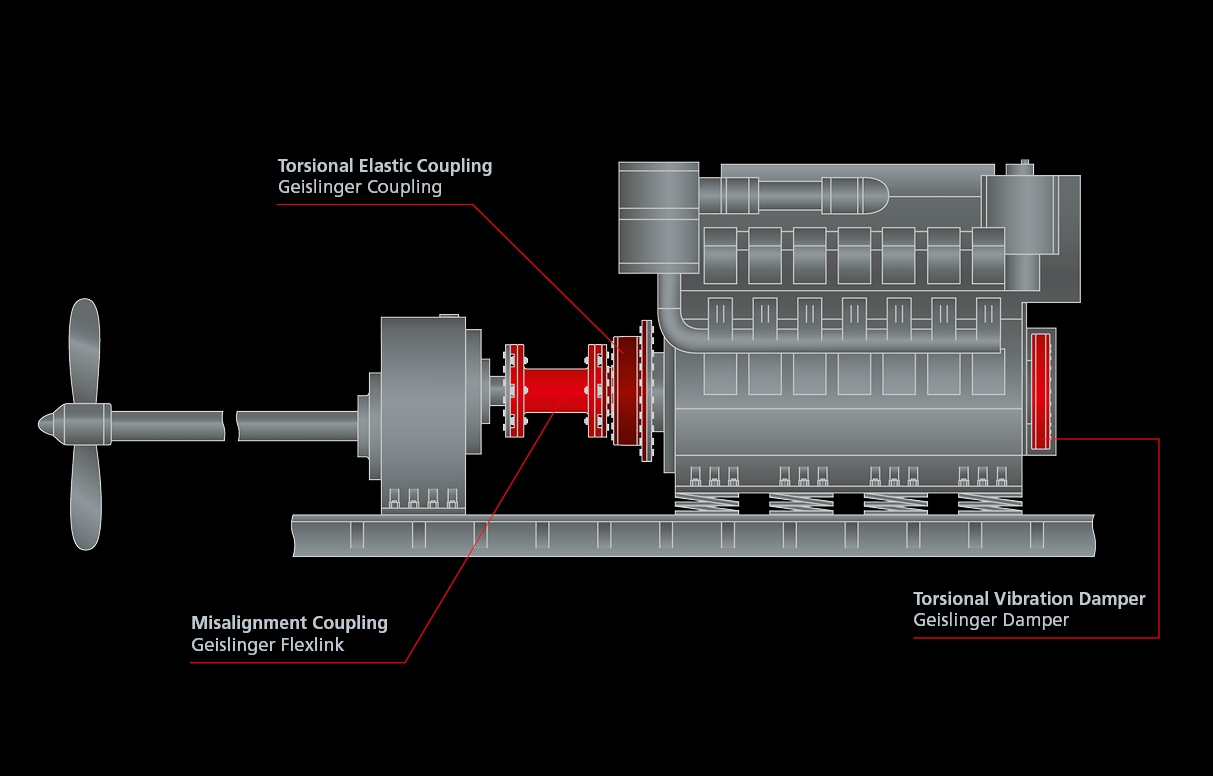

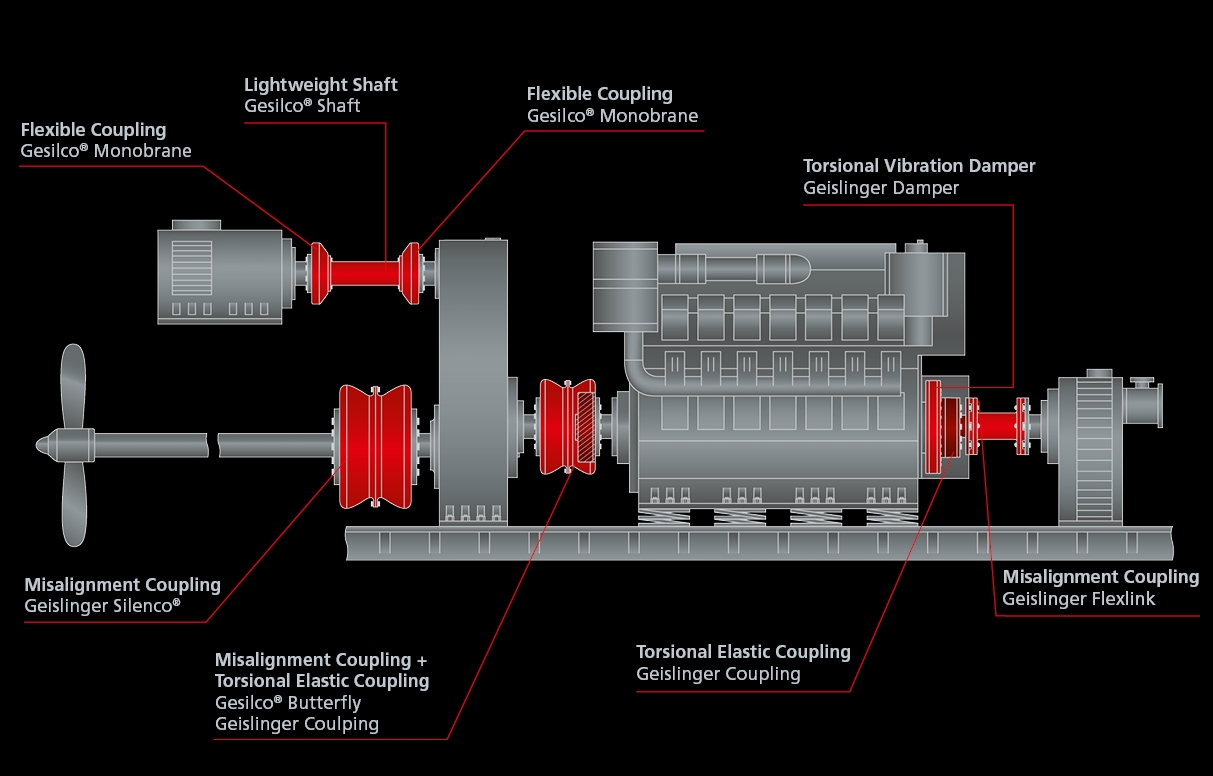

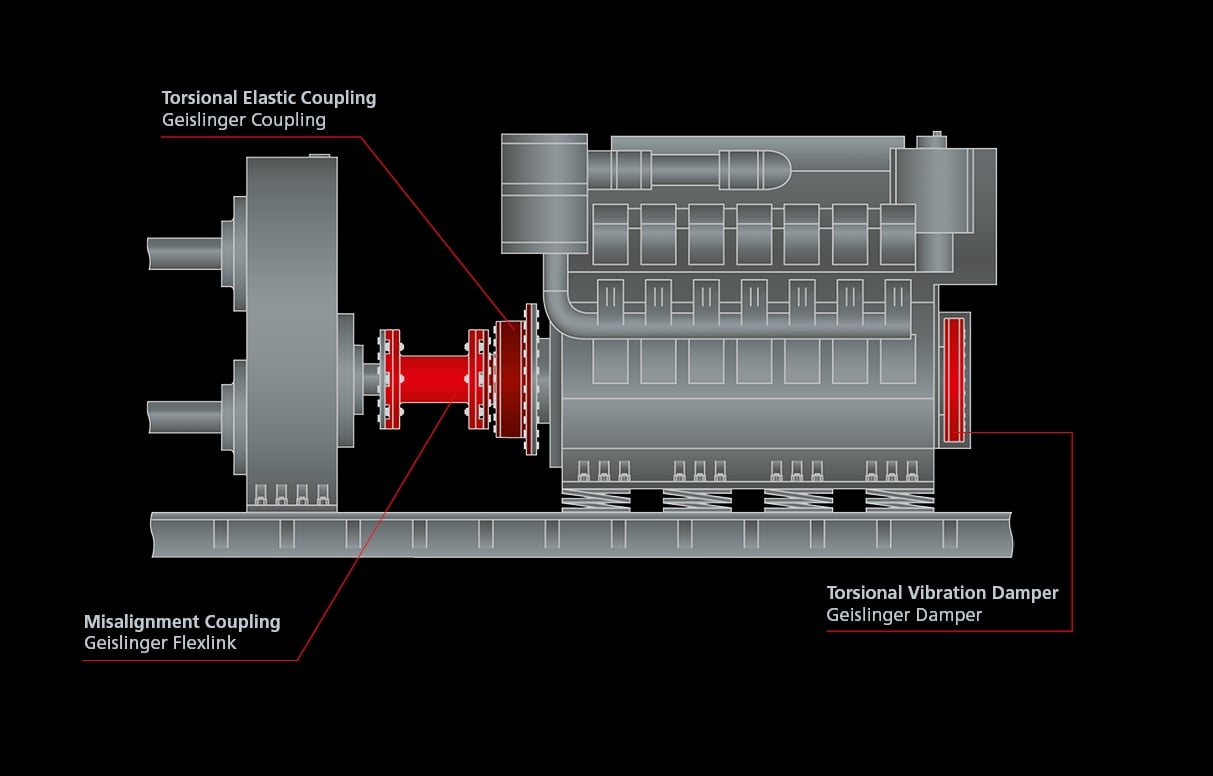

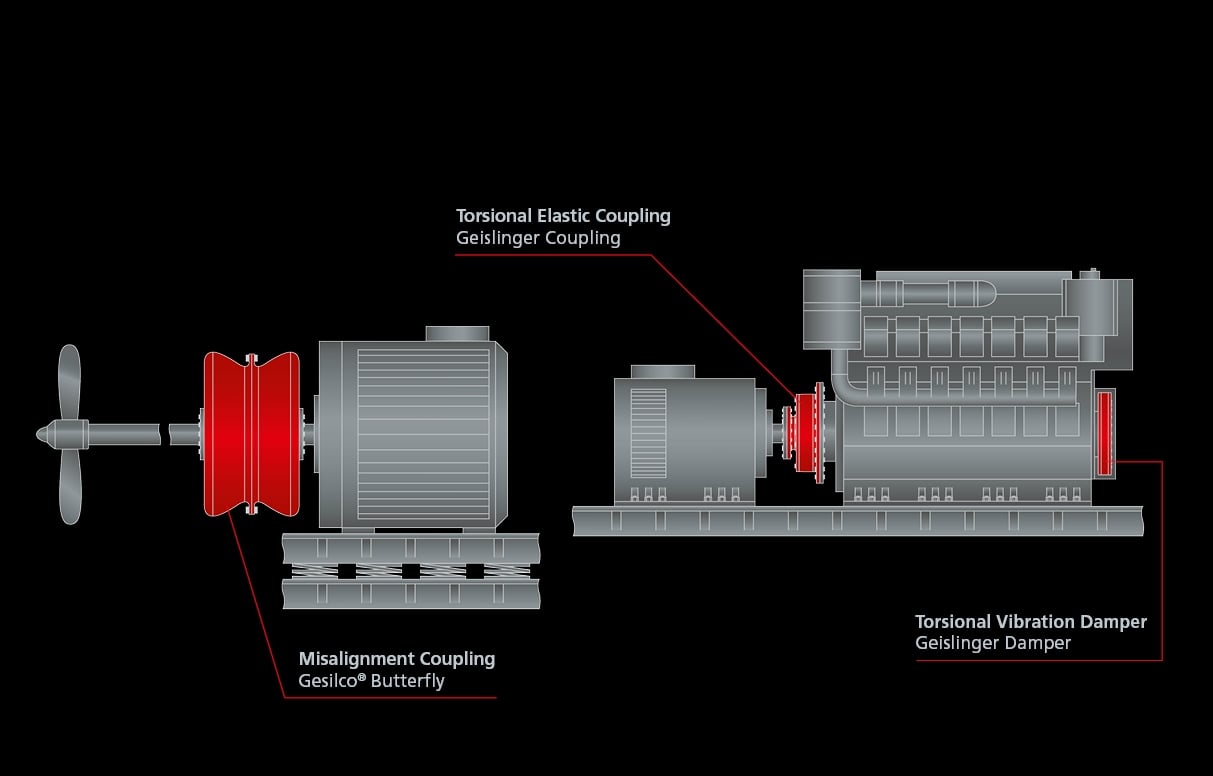

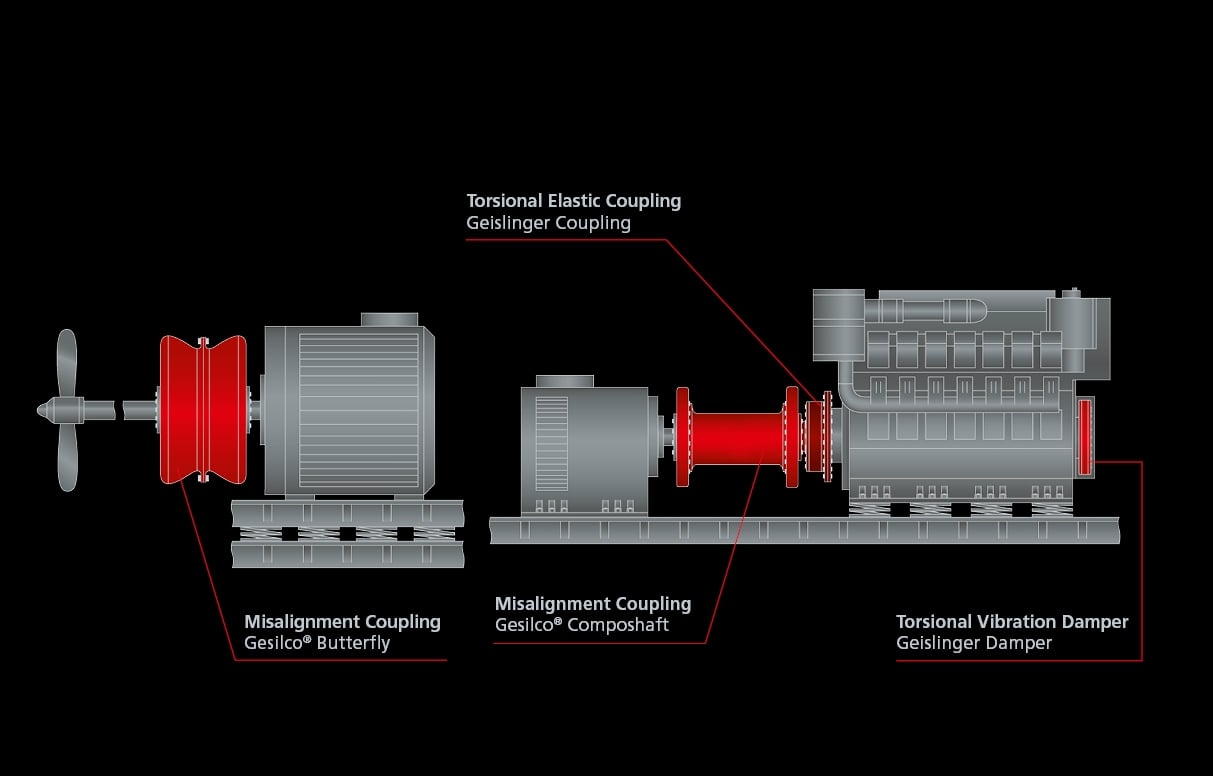

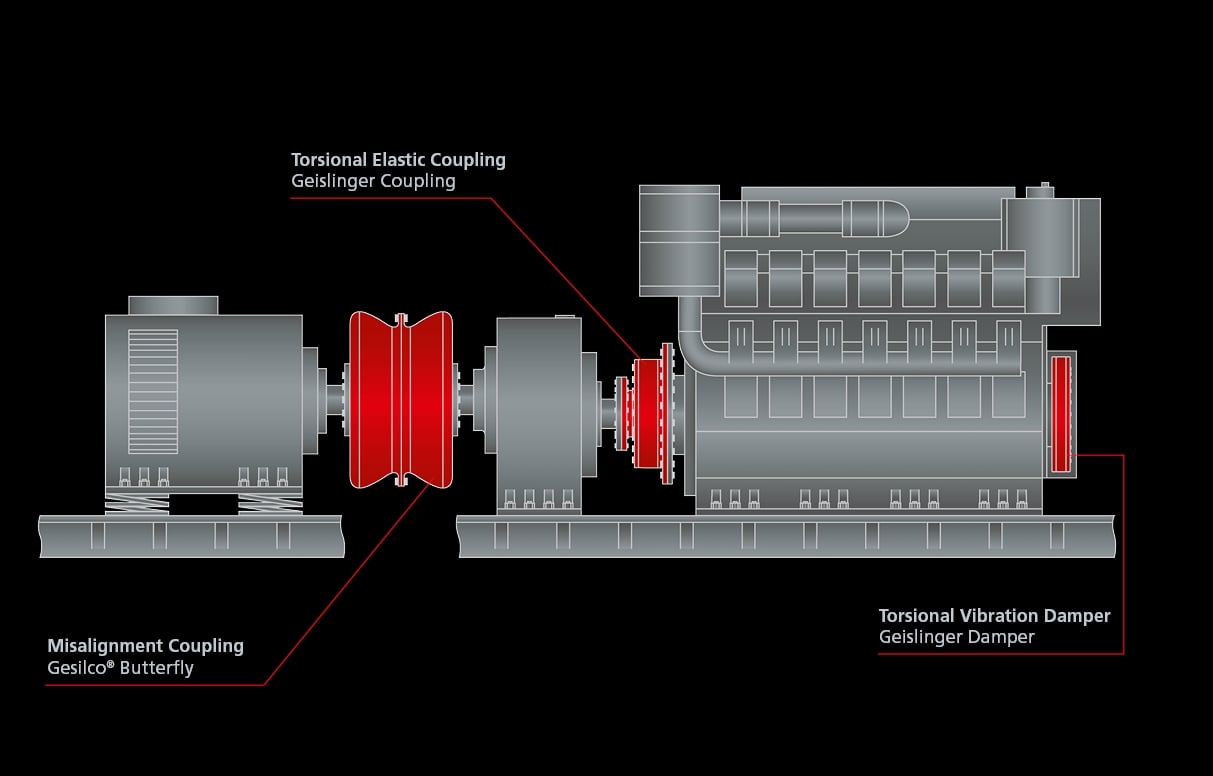

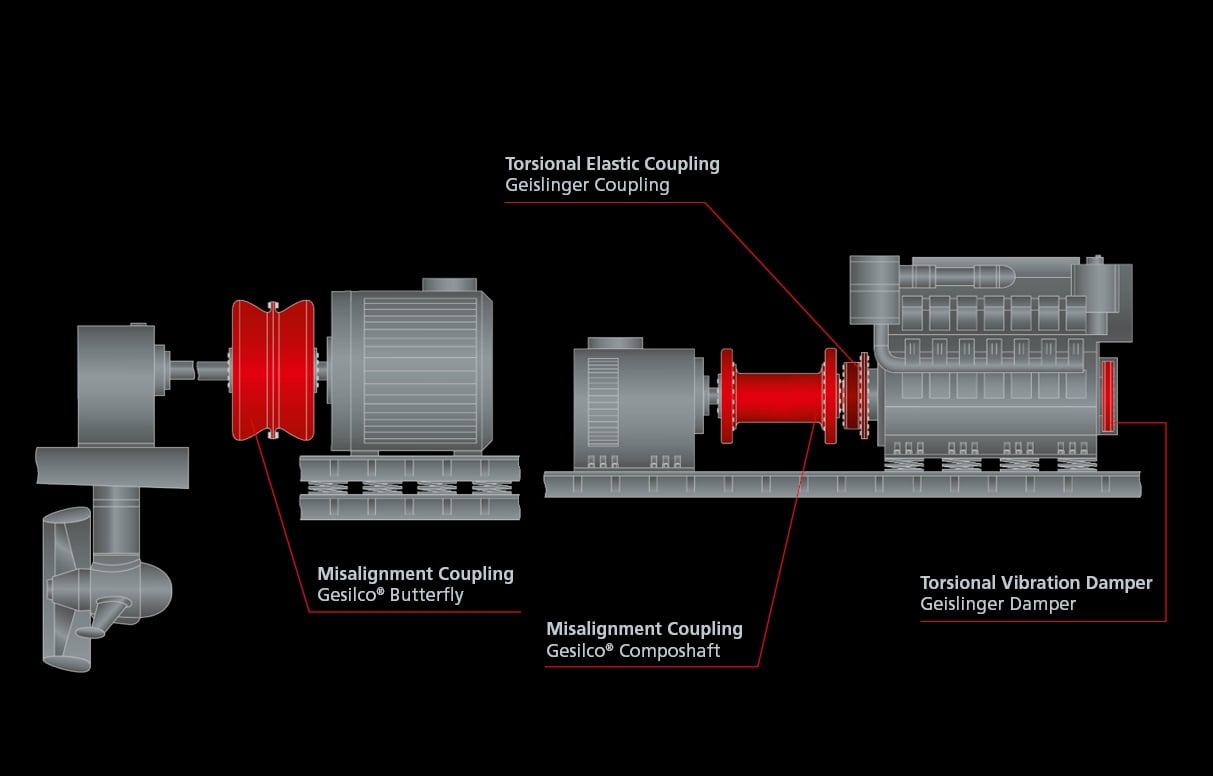

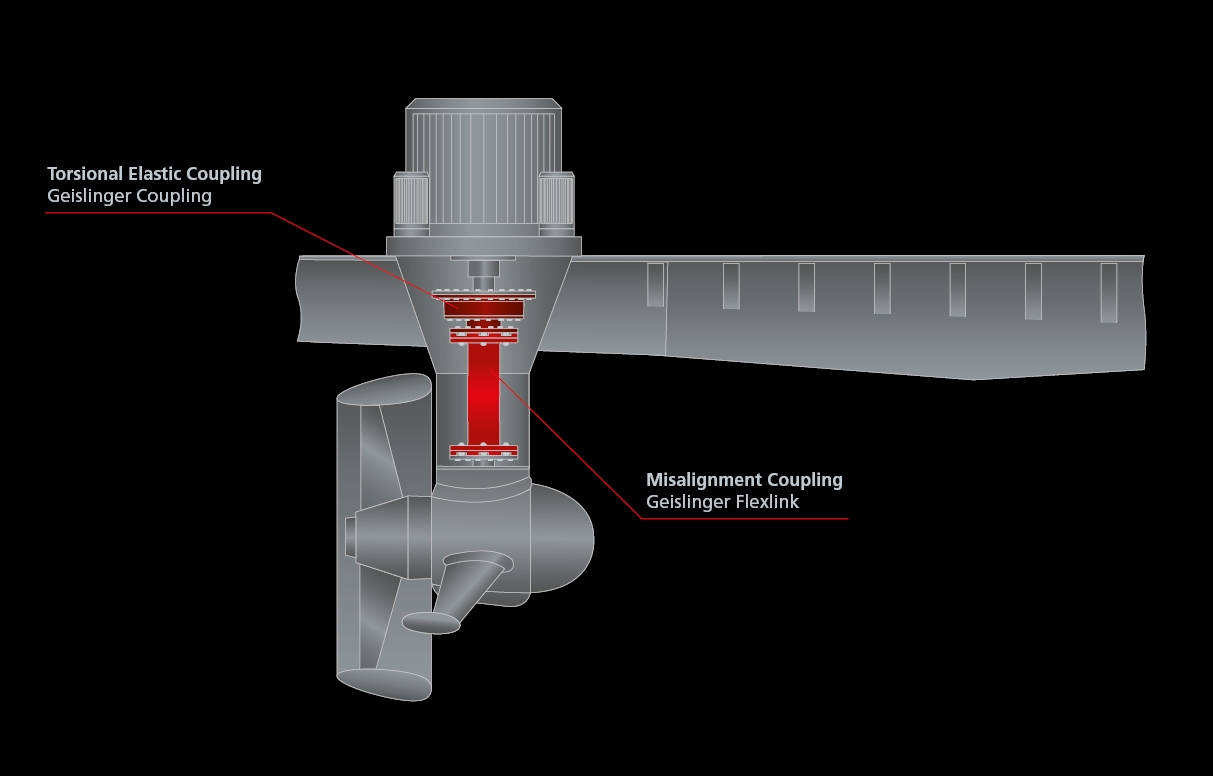

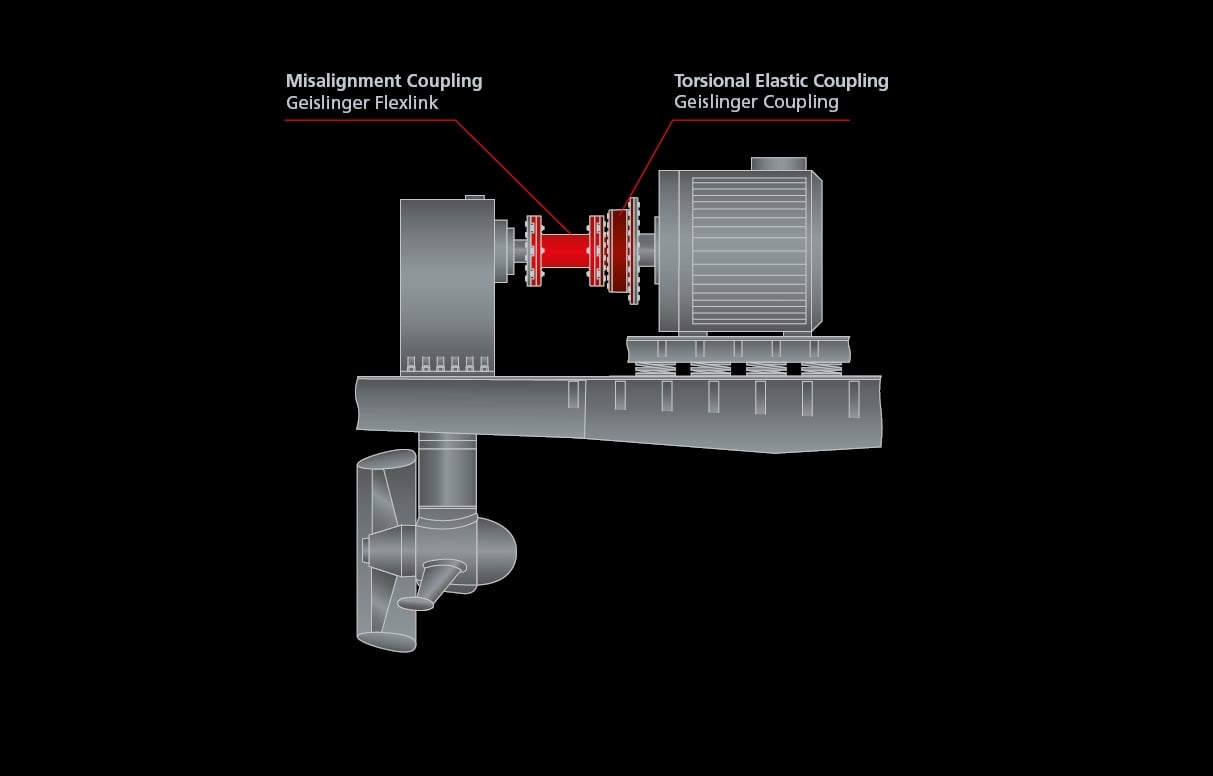

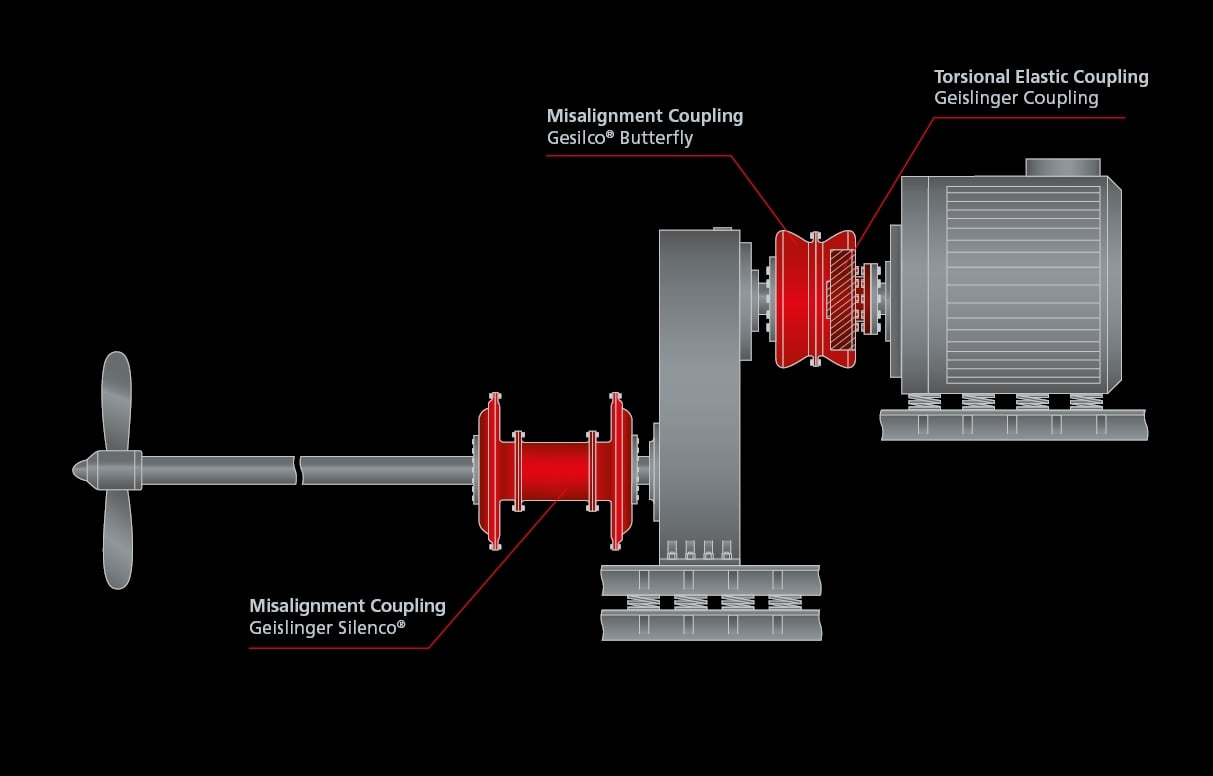

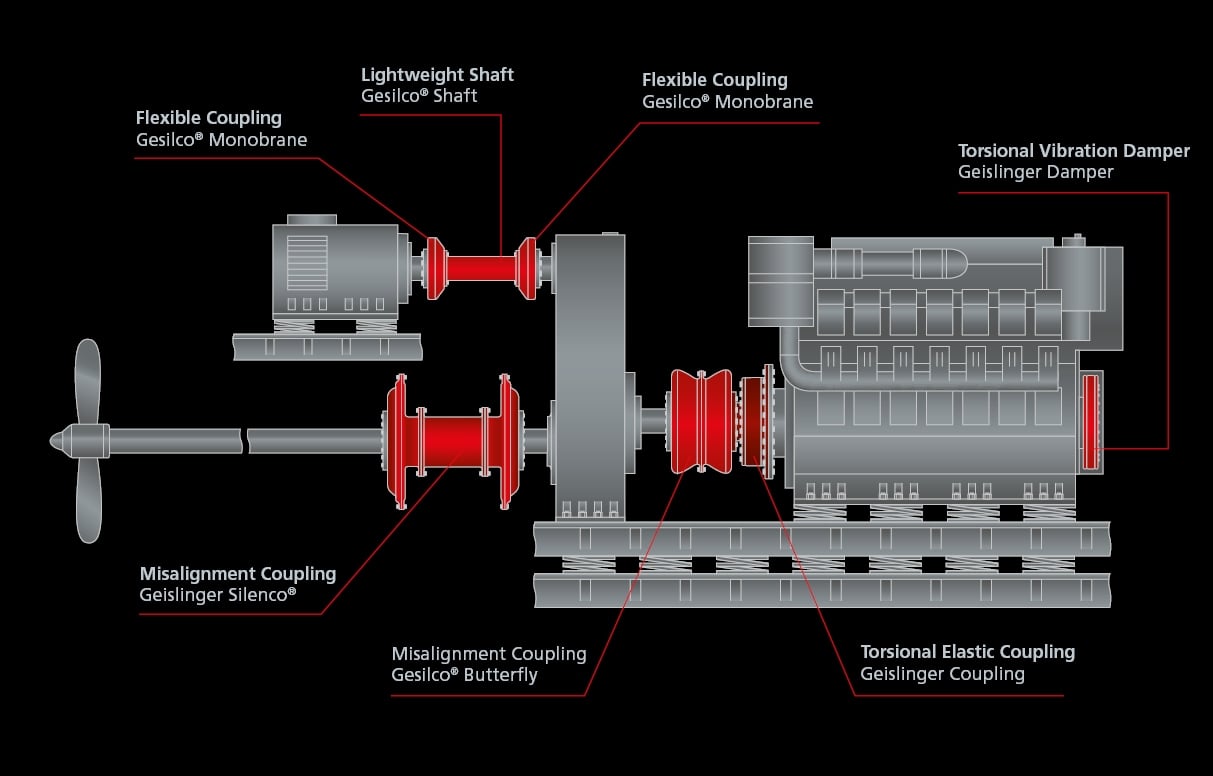

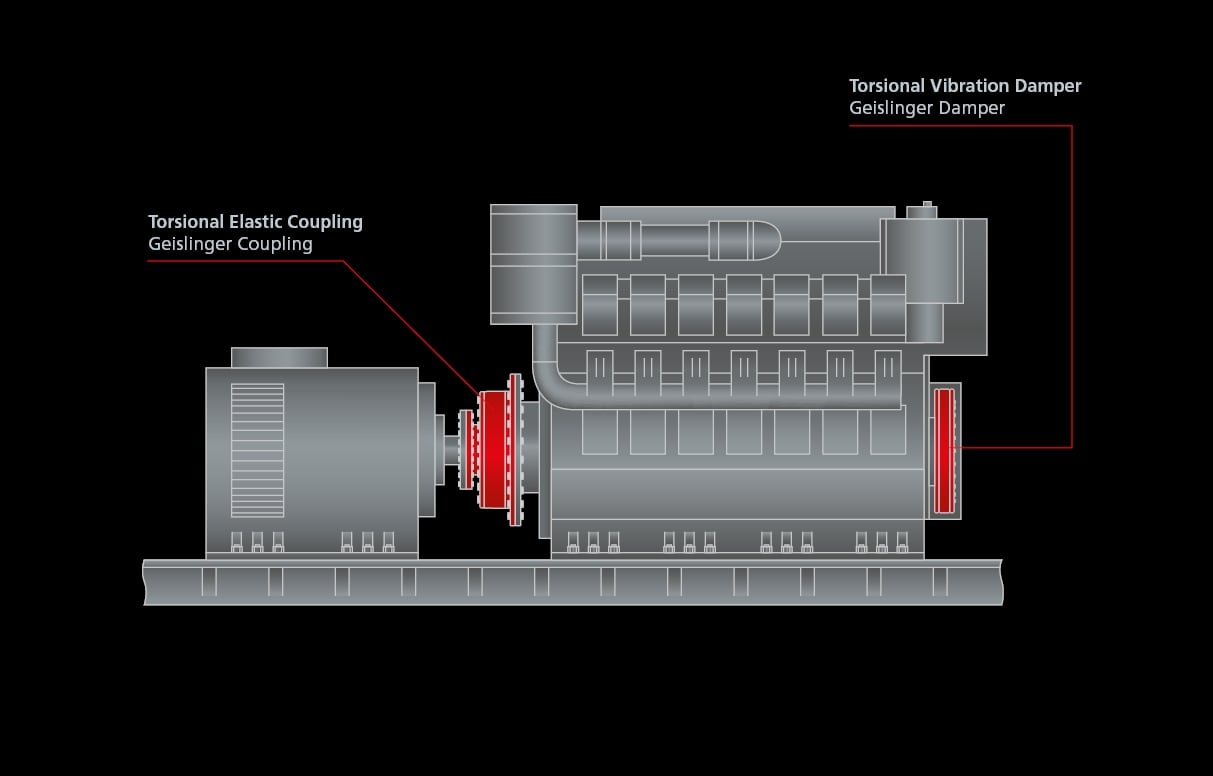

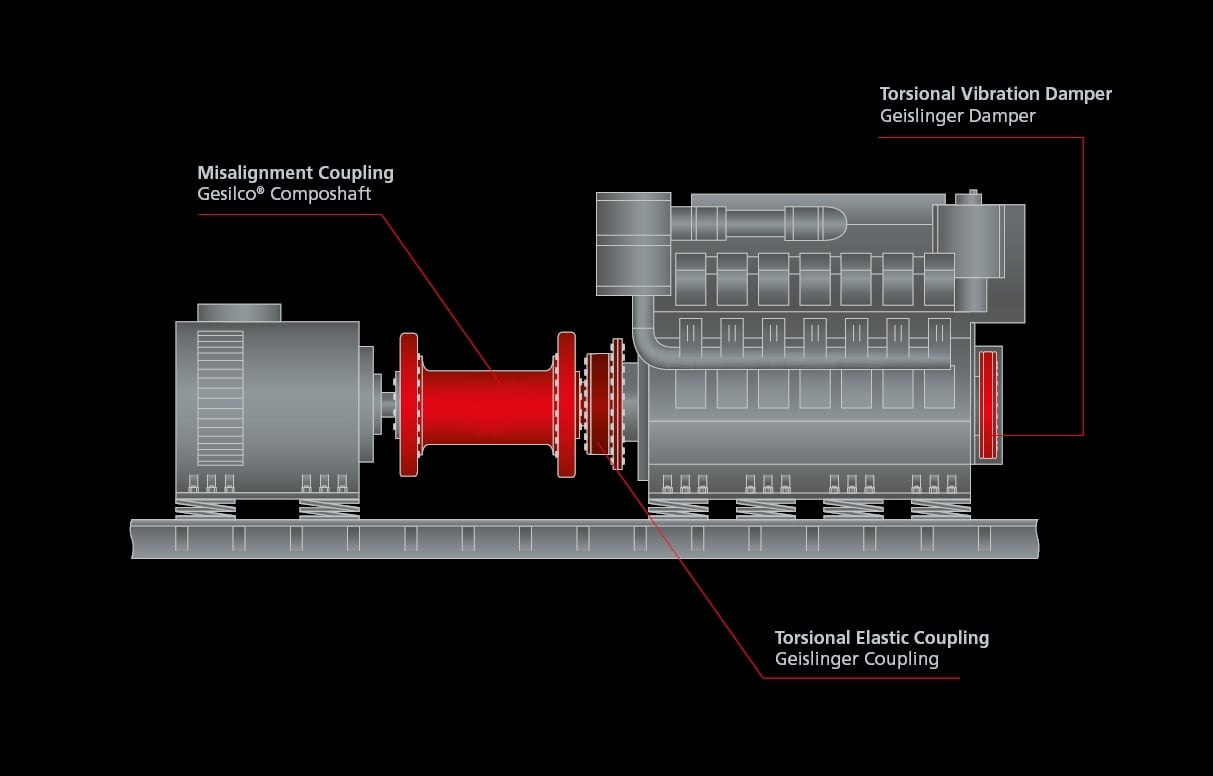

Applications

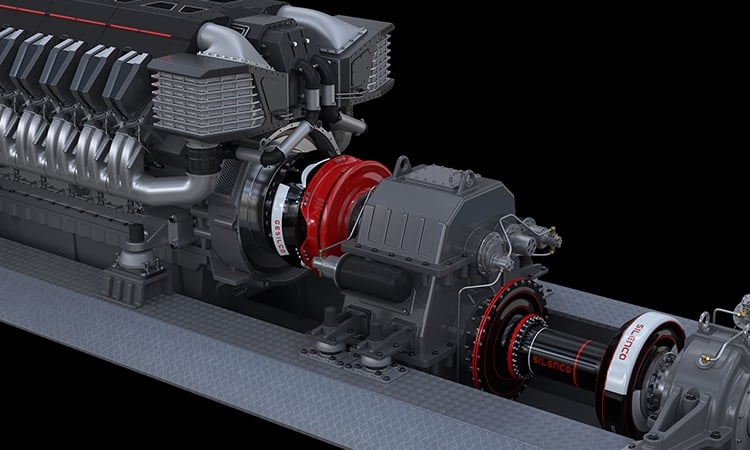

- Marine

- Power Generation

- Off-Highway

- Wind Power & Renewables

- Industrial applications